Whitewashing, or Safety First

If safety is of fundamental importance in the question of what is the best way to paint a brick stove, opt for lime whitewash. The process itself is quite simple, but it is worth remembering that despite all the advantages, this material is not durable. Whitewash cracks under the influence of temperature changes, so painting will have to be done every year.

Of the nuances of using whitewash, it is worth remembering the following...

- Salt is added to the solution to increase wear resistance. In addition, this will save you from the problem of streaks appearing.

- It is recommended to sift the chalk through a sieve, and both water and milk are used for soaking.

- If after mixing the solution has a slightly yellow tint, it is worth adding blue to it.

Painting

After choosing what to paint the stove in the house with, purchasing materials, preparing the surface, they put on protective clothing, take the tools they are going to use, and begin the painting process.

Step-by-step instruction:

- Close windows and doors to prevent drafts. Air currents will increase the likelihood of dust and small particles settling on the painted surface, which will negatively affect the appearance of the stove after complete drying.

- Thin the paint first if it is thick. Some experts recommend filtering the substance through cheesecloth to make sure that there are no garbage elements in it. This is also important if you decide to use a spray gun, so that the operation of the device is not hampered. This is also necessary when using paint of questionable manufacture.

- Regardless of the type of tool that is used, the work involves a certain algorithm for applying the composition: first the edges are processed, then the depressions and inconvenient places, then the main area.

Heat-resistant paints, or a reasonable balance of durability and aesthetics

If you are not bothered by the fact that any paint is a chemical, and therefore has some kind of harm to health (even imperceptible), then opt for paint. True, you need to clearly understand what kind of paint...

- The first thing you need to pay attention to when choosing a material for painting a Russian stove is heat resistance.

- Synthetic compositions, for example, pentaphthalic paints, nitro paints, etc., can withstand heating up to 80°C. An almost ideal option is silicon-organic enamels, which can withstand extremely high temperatures, but their price is quite high.

- Oil paints based on drying oil at high temperatures change their color to a darker one. Moreover, this does not happen evenly, but in spots.

- Remember that a rough surface transfers heat better than a perfectly smooth surface. Also, heat transfer rates will be higher for a dark-colored structure. Another thing is that not everyone will like a black stove, and it is quite difficult to fit it into the interior design.

- Aluminum dyes are also not suitable for bricks.

- If you are not satisfied with the variety of colors among the paints recommended for a brick oven, pay attention to latex compounds that are applied over a special primer with a rough texture. Latex compounds are very elastic: at high surface temperatures they expand, but then return to their original form.

A stove painted with heat-resistant paint in a house or country house looks beautiful, and its surface will not crack or chip for about 10 years. However, it is worth remembering the unpleasant odor of these compounds, as well as the rather long drying period.

Advice from the experts

There are no high temperatures in a brick washing bath, but the materials are affected by moisture. Therefore, the walls can be finished with tiles. The surface is first leveled with plaster. The layer is applied with a thickness of 15 mm. Once the ceramics have been laid, the solution is removed with a rag if it gets on the surface of the cladding.

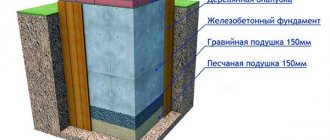

The foundation, floor, walls, windows - all these are parts of a single whole - the baths. Therefore, for its finishing it is better to use materials that combine with each other. For cladding walls, for example, you can use clinker tiles for interior work, and for arranging the foundation, clinker for difficult operating conditions.

Source

Homemade paints for the stove

Is it possible to prepare a composition for painting a stove with your own hands? Of course you can! After all, this is exactly what our distant ancestors did, who had no idea what a construction market or a hypermarket was.

The recipe for preparing such compositions deserves a separate article. This is not to say that the task is too difficult, but at the same time, almost no one now resorts to this difficult path. It is much easier to go to the store and buy everything you need.

It is impossible not to mention decorative options for painting heating structures, for example, in two colors or with original ornaments, with decoratively processed seams, etc. But this concerns not the choice of material, but the method of painting.

You might be interested in watching the video: “Do-it-yourself heat-resistant paint for the stove”

Preparatory process

Having chosen what to cover the red brick stove in the house with, additionally purchase tools for work, clean and prepare the surface.

Main events:

- clean from dust and dirt,

- putty the cracks,

- remove chips.

On a note ! A folk method that will help get rid of minor flaws is to apply a mixture of egg white and homemade milk to a warm oven.

Inventory and additional building materials:

- dye;

- roller, brush, spray gun or compressor;

- tools for cleaning uneven surfaces (soft sandpaper);

- protective clothing: gloves, goggles, mask;

- rags.

A combination of several types of paints in finishing a stove Source rio-max.ru

Important ! In the room before work, the furniture, floor, and walls are covered.

How to whiten

In stores you can find modern compositions for whitewashing stoves; they are made by different manufacturers, but they go under one name - putty. Before use, such a purchased composition must be diluted with water in a ratio of 1 to 2.

After treating the stove with it, its walls will have a well-groomed appearance for a long time and will not fade. Among the popular manufacturers, it is worth highlighting those whose products come at an affordable price and with a high quality composition.

| Brand | Volume, kg | Description | Price, in rubles |

| Master | 1 | For this product, you need to prepare the surface of the oven so that it is dry and dust-free. They can be used to repair small cracks and whitewash walls, ceilings and stoves. |

30

Nova 0.8 Can be used for plastered, wooden and concrete surfaces. 21

BRAVO 16 A water-dispersive composition of the product is used for painting rooms and preparing walls for wallpaper. 960

Diola-006 4 In its pure form is used for sealing cracks, places after removing nails and screws, and restoring chips. After dilution with water, it is used as paint.

115

Flamingo 5 Its moisture-resistant composition can be used for any premises; it is characterized by high plasticity. 110

The best way to whitewash the stove in the house is up to everyone to decide for themselves; you can choose the appropriate one from the given means.

Types of coatings

There are several types of coatings for different surfaces in the bathhouse, each of which has several differences. This applies to general properties, general purpose, etc.

Antiseptic

Wooden surfaces in bath rooms are exposed to high temperatures and humidity. To protect them and make them more durable, you need to use antiseptics. Their main task is to protect the wood from mold, mildew, discoloration, blue stains, and rot. Antiseptics can repel rodents and insects.

Fire retardant

Fire retardant is an additive that changes the degree of fire protection of wood, polymers, and fabrics. The wooden panels that will be used to finish the steam room near the stove must be impregnated with this composition.

Steam room (Photo: Instagram / gefest_official)

Oil and wax impregnations

They allow you to improve the technical characteristics of wood and change its external design. Advantages of oil impregnations:

- low price;

- availability (impregnation can be bought at any hardware store);

- ease of use;

- attractive matte shade;

- environmental cleanliness.

Disadvantages of oil:

- Every 3 months you need to renew the coating and polish the surfaces after applying oil.

- Grease stains on oiled surfaces appear stronger than on other decorative coatings.

Types of oil:

- tung;

- teak;

- tar;

- linen;

- toning.

A separate impregnation option is wax oil for wood. It protects wood from the destructive effects of moisture. The finished wax impregnation consists of 3 components - oil, inorganic additives, beeswax.

Bath oil (Photo: Instagram / galmet_vko)

Dye

Kinds:

- Acrylic. Suitable for painting indoor and outdoor surfaces. Suitable for wood, stone, concrete, brick. There are paints for facades and floors.

- Silicate. More often used for finishing facades made of brick and concrete. The finished coating can withstand various aggressive factors. Average service life is 20 years.

- Silicone. Suitable for painting different surfaces in the shower. The silicone composition is resistant to temperature changes and moisture.

- Organosilicon. Decorative coating resistant to high temperatures. The paint will fade when exposed to high heat, but the integrity of the coating will not be compromised. Silicone enamels are used for concrete, stone and brick facades. Suitable for metal stoves.

A universal option is acrylate varnish. This is a water-based varnish that is suitable for coating walls, floors, and ceilings.

Varnish

Can be used to cover surfaces in dressing rooms and recreation areas. It is prohibited to use ordinary varnishes for the steam room. At high temperatures, they begin to release harmful substances, crack, and fall off the walls.

Bath varnish (Photo: Instagram / amur_kudesnik)

Calculation of the number of tiles

To do this you need to know a few things:

- the total area of all oven surfaces on which the tiles will be laid;

- the dimensions of possible areas with a narrow decorative layer of ceramics;

- dimensions of ceramic tiles.

To calculate the area, you will need to subtract the dimensions of the blower doors, combustion chamber, and gaps between finishing parts. For furnace cladding, it is recommended to make gaps of up to 10 mm.

If you plan to make a narrow finishing belt, make barriers and other decorations, the area of such a layer is taken into account in the calculation. Now knowing the dimensions of the tiles, we can easily calculate the number of tiles of the main layer and decorative belt.

We divide the total surface area by the area of 1 tile and get the number of parts required to complete the work. If the doors on the firebox and ash pan are small, they can not be subtracted from the total area. For reserve, it is recommended to increase the number of tiles by 20% of the calculated value.