In the process of heating the room, a sauna stove sends about half of the heat into the air, or more precisely, into the chimney, so the idea of building a sauna stove with a water circuit not only looks attractive, it is a great way to solve a lot of problems at the same time. If, of course, the sauna stove with a heating circuit is made at a more or less acceptable quality level.

A sauna stove with a heat exchanger: what is it?

The idea of using as much heat as possible from a stove is not new. A good application is to use it to heat the coolant. For your information! The principle of any heat exchanger is to ensure maximum contact of an insulated liquid carrier with a heated surface to increase heat transfer between them.

Many designs have been invented to implement this. Let's look at them according to the purpose of the heated liquid.

Model range overview

The Teplodar product range is not limited to equipment for baths and saunas. It includes heating boilers for the home, fireplaces, and electrical equipment. But the basis of production is stoves for saunas and baths.

Teplodar offers consumers the following models:

Siberia – sauna stove. Allows you to get high-quality dry steam and warm up the room in 30 - 40 minutes. Low humidity combined with high temperature, which the model creates, will allow you to feel the effect of a classic Finnish sauna. The Siberia Panorama modification with a door made of heat-resistant glass is available for sale. This option allows you to feel like you are sitting in front of a fireplace.

Sahara - the model also belongs to sauna stoves, but has a more advanced design. Owners of this unit can get dry and wet steam, since the oven can operate in 2 modes at once. A two-chamber heater, allowing the stones to be heated from 5 sides simultaneously, will ensure their uniform and rapid heating. The model provides the possibility of installing a multi-section steam generator capable of “organizing” good steam after just 20 minutes of combustion.

Siesta is a model that will not only warm up the steam room, but also allow you to cook a barbecue. Siesta will efficiently heat a steam room with a volume of up to 20 cubic meters. A vertical firebox closed on all sides by a convector and a closed heater in the rear part of the structure will allow the stove to be installed even in small steam rooms. The device is equipped with a built-in steam generator, an Anti-Smoke system and dampers in the chimney and door that allow you to regulate the intensity of combustion.

Sibirsky Utes is a stove equipped with a forged mesh. It is endowed with high efficiency and has excellent heat transfer dynamics and the ability to create light steam. Excellent convection, obtained due to the presence of free space between the fuel channel and the stones, helps to achieve the effect of a Finnish sauna with heating temperatures of up to 140 degrees. Thanks to the large volume of stones, the steam is light and comfortable for the body to perceive.

Kuban is a bright model equipped with 2 heaters. Closed, located inside the body, thanks to the supply of water to it from the dispenser built into the tank, it helps to obtain light steam. Open allows you to quickly warm up the room. The model is designed for storing firewood from the dressing room. This allows you to keep the steam room clean.

Blast furnace is a new product in the line of Teplodar furnace models. Equipped with a vertical stainless steel firebox and a casing that closes on top. The main feature of the unit is the presence of a heater inside the firebox. This design allows the stones to be heated to ultra-high temperatures and produce finely dispersed steam.

Cascade - models that stand out from the entire range with their magnificent design. The body of these kilns has smooth contours and holds a lot of stones. The firebox of the Cascade model is made of high-quality metal with a thickness of 4 mm, which extends the service life of the unit.

Rus is a specialized line of wood-burning stoves for Russian baths. The use of these units allows you to create an optimal balance of temperature and humidity, characteristic of a Russian steam room.

Bugrinka - a model that will appeal to true connoisseurs of the Russian bathhouse, because a large mass of stones placed in the stove participates in the formation of the microclimate. A powerful mesh stove is installed and heated from the steam room. A reliable door with a locking mechanism prevents accidental opening and spillage of hot coals.

Application area

Wasted heat can be used for two purposes:

- for heating water to be used for washing;

- for heating rooms.

Of course, such goals can be combined if the stove is powerful enough. After all, we will, in fact, be taking away part of the heat that would otherwise be used to heat the steam room (or atmosphere)).

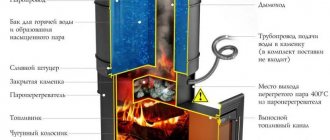

Scheme of heating water in a remote tank with a samovar-type heat exchanger (video with explanation, see below)

Bath stove with water heat exchanger

This is the first time. We are talking exclusively about water (no antifreeze), the consumption of which depends on the number of people who can wash in the bathhouse at the same time and other factors. In any case, you can’t do without a spacious tank. And here again you have options for where to place it:

- some place the tank directly on the stove , which must have an appropriate design for this. Water is supplied to the washing room from the steam room;

- others use a heat exchanger , and the tank itself is placed in an adjacent room, from where it is connected by two pipes to the heat exchanger.

Both designs of stoves with a tank have a right to exist, and the choice is yours.

Bath stove with heat exchanger for heating

If instead of a tank you connect a heat exchanger with a radiator, you get an autonomous heating system .

Here again you have two options):

- or create a design that is based on phenomena such as convection and gravity;

- or force the coolant to forcefully move in the system - for this you will need a pump, and therefore electricity (! A separate section is devoted to electric stoves).

If the bathhouse is small, then there is no need to bother with even the simplest system, because usually the stove is enough to heat adjacent rooms . But what matters here is what kind of winters you have. It happens that a small bathhouse needs additional heating.

It was already mentioned above that it is possible to combine heating of water for washing and heating. In fact, you can make two parallel systems, and use antifreeze rather than water for heating. For this purpose, one heat exchanger will need to be placed inside the stove, and the second - on the chimney. From the point of view of increasing the efficiency of the furnace, this option is simply excellent.

On a note! When creating a heating system, do not forget about the expansion tank , which will absorb excess coolant.

Brick or metal

The choice of furnace material matters only from the point of view of individual preferences and conditions:

- Price . Based on the cost of the final product, purchasing a metal furnace will be cheaper than purchasing material and paying workers to build a brick furnace. If you do the masonry yourself, the final cost will decrease due to the deduction of payments to hired workers, which will significantly affect the price.

- Bath area . Metal stoves take up less space, so if the area is small, the choice is definitely in favor of a metal product.

- Difficult to install . A brick stove requires a separate foundation, which lengthens the installation period; a metal stove is installed on a lighter base. The wood-burning sauna stove is quite popular and is practical.

- Sometimes the decisive factor is a photo of a factory-made metal stove - the range of modern manufacturers is distinguished by functionality and attractive design.

Whatever material the stove is chosen from, installing a heating circuit will make the choice more successful.

Types of devices

The furnace provides several options for placing heat exchangers:

A coil or water circuit is a steel structure that can be located both inside the furnace and outside , for example, between the furnace wall and the casing. Its use is not limited to metal stoves - water circuits can also be built into brick ones.

The shape and size can vary significantly from a simple C-shaped, once bent tube with fittings , which is located inside the firebox, to a water jacket around the entire body.

IMPORTANT! The correct location of the metal pipe inside the furnace is always such that the open flame does not touch it in any area. It should be remembered that even stainless steel is subject to oxidation in a flame.

A large tank that touches the walls of the furnace with a wall or bottom (or both) can also be considered a type of heat exchanger.

For your information! By taking heat away from the stove body to heat water, you reduce the operating power of the stove.

But in the design of all furnaces there is an element that in most cases (but not in all!) becomes the cause of significant heat loss - this is the chimney, where very hot furnace gases are sent (if the furnace does not have a smoke circulation system).

The second type of heat exchangers tries to correct this shortcoming. For this purpose, either a small flow-through tank of 5-10 liters , communicating with a large tank outside the steam room, or a full-fledged tank, from where hot water is supplied to the washing room. (In the latter case, there are more difficulties with fastening.)

Photo: samovar-type heat exchanger

Photo: heat exchanger tank on a pipe

By the way! The external tank, among other things, also serves as a heater for the room in which it is installed (dressing room or washing room).

Making a potbelly stove

Initially, it is necessary to draw up a drawing diagram indicating all the dimensions of the parts and prepare the necessary tools for performing metal work (welding, grinder, pliers) and materials.

After cutting the metal, the following actions are performed:

The main elements are welded at right angles: the bottom and walls. Except for the front.

It is important to know! It is recommended to install the bottom of the heating structure at a distance of at least 30 cm from the floor level. Installed metal legs will help reduce the strong temperature effect on the floor covering

The furnace space is subject to zoning, namely, a grate or a sheet of metal is welded between the firebox and the ash pit, in which backlashes are drilled to remove ash.

- It is necessary to make an opening on the front wall to mount the doors. Now the front part can be welded to the remaining elements.

- Hinged hinges are added to the sides, after which the doors can be installed according to the location diagram.

A chimney pipe must be welded at the top of the stove structure. After completion of the work, all seams are cleaned and checked for defects. The next stage is the installation of the water jacket.

How it works

It is easy to guess that in the case of a flow-through water circuit or a tank mounted on a chimney, it is necessary to ensure constant circulation of liquid between it and the storage tank outside the steam room.

This can be done either through the natural laws that water obeys (and such a system is considered open), or with the help of a pump that provides forced circulation.

IMPORTANT! Natural circulation based on gravity and convection is preferable. Connecting pipes must have a diameter of at least one inch and a length of no more than 3 meters.

Look at the diagram above, which clearly shows how the pipes should be positioned so that the water rises and falls freely. Below is a video explaining the diagram.

DANGEROUS! Before lighting the stove, make sure there is water in the system!

Video

Watch a short video that explains the above diagram of a stove for a bath with a heat exchanger for water (this principle can also be used for heating) and shows an example of its budget implementation:

Installing a coil on a chimney

For small steam room ovens, heat exchangers can be installed directly on the chimney. The design of a water heating coil is practically no different from built-in heat exchangers; the only inconvenience is the need to install an additional storage tank for hot water.

Many owners of steam rooms install both types of heat exchangers on the heater stove, the internal one made of alloy steel and the external one made of copper or a copper alloy. The first water circuit is used to produce hot water and boiling water, the second is constantly filled with liquid and looped into the heating system.

Popular furnaces with heat exchangers

Cast iron stoves are deservedly popular among lovers of Russian baths, but how are they combined with heat exchangers? As it turns out, they combine perfectly.

Cast iron stove

To get started, we recommend visiting the website of the Petrozavodsk stove manufacturer Karelia. Among the products offered to visitors are components, among which there is a disk-shaped heat exchanger, apparently attached to one of the walls of the furnace. Thus, you can purchase both a stove and an exchanger at once. As an option, they also sell mounted tanks for the chimney.

Cast iron stove with heat exchanger for a bath. Photo source

Vesuvius stove

Vesuvius stove with heat exchanger for a bath

The stove manufacturer Vesuvius also provides the opportunity to simultaneously purchase a stove (and in its catalog you will find both steel and cast iron stoves) and a heat exchanger . The buyer has a choice of three models - two “samovars” for the chimney, differing in capacity, and one rectangular heat exchanger, which takes heat from the stove wall.

photo of heat exchangers on the Vesuvius website

Stoves for baths "Termofor"

There is a message on the Termofor website that the manufacturer took into account customer preferences and produces the most popular models - Tunguska 16 and Tunguska 24 - with already installed heat exchangers , which require an external location of the storage tank. The material of the exchangers is high-quality food grade stainless steel, 2 mm thick . Depending on the buyer’s choice, the placement can be varied by installing it either on the right or on the left wall of the stove.

Useful video

Termofor sauna stoves with a heat exchanger may be built well, but there are negative reviews. Watch the video and see what it looks like:

Several alternative options

Despite the fact that the options described above are the most popular and considered optimal, I decided to briefly mention some alternatives. In fact, they are varieties of stove heating, but have their own characteristics.

For example, if you have such capabilities, then you can install a diesel fuel boiler in your bathhouse. But this option requires a separate room (diesel fuel does not smell much), and you need to think about fuel storage.

There are also pyrolysis heating boilers. The undoubted advantage of such a boiler can be considered a very long, almost complete combustion of fuel. The disadvantage is the high cost and difficulty of operation (for example, raw wood does not burn in it).

It is also possible to use long-term combustion boilers, capable of burning a separate batch of fuel for up to 5 days, maintaining the desired temperature. There are even options for high-quality graded coal. But this is rather an “industrial” option, which is not suitable for a good traditional bath.

DIY making

Despite the availability of different options for sale, you can try your hand at making a heat exchanger yourself. It's not that difficult if you have welding experience. In any case, it’s easier than making a stove from scratch.

But before you get started, you need to do a little calculation.

Calculation of heat exchanger power and area

It was already mentioned above that heat exchangers connected to the body take away part of the furnace power. Therefore, the first rule will be the following:

IMPORTANT! The heat exchanger power should not be more than 1/10 of the furnace power.

The second rule is related to the length of the pipes: if the system is gravity-fed, then you should not extend the pipes further than three meters. The pump in the system eliminates such restrictions. But the pump is installed more often when the coolant is used to heat rooms. However, if the storage tank is not located too high, you can only wash with a hose. If this is inconvenient, then you need to either take the tank into the attic and insulate it, or install the same pump.

The third rule concerns the volume of the heat exchanger (if it is a small flow-through tank and not a coil). The water in it should heat up within a couple of hours. If it’s longer, then the volume is too big. If it is faster, then it is better only at first glance - the water should not boil, this will cause scale, steam, testing the expansion tank, and other problems.

Now, actually, the calculation itself:

The power of the heat exchanger depends on its area: 9 kW for each square meter of exchanger . The area is quite simple to calculate: if it is a coil, then multiply the circumference (3.14 * diameter) by the length of the pipe. If this is a “samovar” heat exchanger, then take the diameter of the inner pipe, multiply it by the number Pi, and multiply it again by the height of the “samovar”.

Power = resulting area in sq. meters * 9 kW.

If the exchanger hangs on the chimney, you can ignore the rule of deducting its power from the power of the stove. Only if he is on or in her body.

You can calculate the power required to heat a room using the same principle as for a steam room, that is, based on the volume of the room. In the steam room, a kilowatt per cubic meter is taken, but the adjacent ones do not need high temperature, so focus on half the value.

Knowing how many kilowatts are needed to heat a washing room, you get the area of the heat exchanger, and from it the length of the pipe for the “samovar” or coil.

Let's consider a couple of options for self-manufacturing heat exchangers.

Let's assume that you decide to increase the efficiency of the stove by installing a heat exchanger on the chimney.

- The thickness of the steel required for this is 2.5 mm.

- In addition to the sheet material, you will need two pipes with different diameters.

- The smaller one should be adjacent to the chimney pipe, the larger one should be 5-10 cm wider than the first one.

- Two circles are cut out of sheet metal to fit the diameter of the larger pipe, then a hole is cut in the center to fit the diameter of the smaller one and everything is carefully welded.

- You also need to make holes for the pipes through which water will come and go.

- The pipes are threaded and must match the diameter of the connecting pipes.

ADVICE! After checking the tightness of the seams, installation on the chimney and routing of pipes, it is recommended to insulate the heat exchanger using mineral wool and foil - this will dramatically increase the rate of water heating.

Another option for a heat exchanger for a chimney is a coil made of a copper tube with a diameter of 10 mm, which is made to tightly wrap around the chimney pipe. 1.5-2 meters of pipe is enough. The ends of the coil are inserted into the nuts, flared under the fittings, and then the fittings are screwed to the nuts.

Note! The copper tube must be flared exactly under the cone of the fitting so that they eventually fit tightly against each other. Be careful because this is where leaks can occur in the future if you flare at an uneven thickness.

Here are a couple of videos on the topic:

Video

How to bend a copper tube yourself with a pipe bender.

Without pipe bender.

Design Features

The developers of Teplodar stoves managed to implement the rule of the “golden ratio” in their products.

Main design features of the units:

- A body without sharp corners, which is ideal for steam rooms with different areas and interiors . This shape prevents the risk of injury during maintenance.

- Equipped with a two-chamber mesh for stones . The Sahara Profi and 16 series configurations have a dome design and are equipped with a central chimney. The firebox in the stove has a symmetrical shape, the chimney is removed from the walls of the steam room. It also has convection channels that allow you to quickly heat the steam room.

- Converters with a special funnel . From it, water enters the apparatus and circulates through channels that are heated to a certain temperature, which leads to its evaporation. The grate is made of cast iron.

- Dispenser taps on the tank . Thanks to them, it is possible to regulate the humidity level in the steam room of the bath. The feeding force can be adjusted from jet to drip mode.

- The chimney diameter is 115 mm, the most common . Chimney outlets are located in different ways: offset or centrally.

The manufacturer provides additional equipment:

Gas-burners;

Models with built-in water tanks can be equipped with mounted or remote tanks.

Principles of installation, connection and safe operation

- Installation options depend only on the choice of location of the exchanger. The most difficult thing will happen if you decide to place it inside a finished oven , where it was not originally planned. For this you will have to disassemble the case and make holes. It is much easier to use a hanging structure or put a coil or a “samovar” on the chimney pipe.

- As for the pipes that connect the heat exchanger to the tank, for a gravity-flow design it is important to observe slopes, and also remember that the fastening of the pipes should not be rigid - allow them to “walk” freely during thermal expansion.

- The material for pipes is best copper , and connections are brass . When purchasing seals, pay attention to their ability to withstand high temperatures.

Operating safety depends on your awareness. The main thing is not to forget about two things:

- when leaving the bathhouse, you need to drain all the water from the system;

- You should not start heating without making sure that the storage tank is full of water.

If a brick oven with an internal water circuit is flooded and you forgot to add water in time, it is better not to do this when the oven is heated.

It is also important to prevent the liquid from boiling in the system.

Principle of operation

Heating from a stove with a water circuit is represented by a simple diagram. The designated coolant heats up during fuel combustion, after which it moves through a system of pipes, warming up the surrounding space.

Modernized stoves and solid fuel boilers have inherited the functional features of the “Swedish” boiler, which is well known to many consumers. Thus, the principle of operation of the Swedish installation is that the laying of firewood for kindling is preceded by filling a special tank with cold water. During the combustion of solid fuel, the water masses warm up gradually, but subsequently they also slowly cool down.

Sauna stoves with a heat exchanger: reviews

Reviews from consumers whose washrooms receive hot water from a heat exchanger in a steam room or whose bathhouses are heated with its help are usually positive.

According to one of the users, he kept a boiler in the bathhouse for some time to heat water, but for the sake of saving money he decided to switch to a cheaper design. And after thinking a little more, I didn’t buy a ready-made one at all, but twisted the coil myself and installed it inside the oven. I'm pleased with the result.

Also, those who purchased a stove with a built-in water circuit do not complain, because the water becomes hot in an hour and a half, and the steam room arrives in two.

There are no problems with the heating systems either - the radiators installed in the cold dressing room by another bathhouse owner solved the problem of cold, the stove copes well with heating the combined washing room and steam room, and with heating the dressing room.

***

Are you convinced that a sauna stove with a heat exchanger is better and more profitable than a boiler? It will heat the adjacent rooms and provide hot water for washing. And at the same time, the efficiency of the stove will increase if you hang the exchanger on the chimney pipe. Exchangers are inexpensive, but it’s easy to make them yourself. In general, we recommend an affordable solution.

Advantages of stove heating

- The main advantage of stove heating with a water body is that there is no need to purchase expensive units and components.

- Over many years of use, the stove will only need minor cosmetic repairs. This is much cheaper and easier than taking expensive equipment for service.

- Free design.

Craftsmen can build a stove of any shape and size, and the owner can decorate it to his liking if he wishes. The stove can fit perfectly into the design of the room - If we compare stove heating with a water circuit with solid fuel boilers, then there are additional advantages due to the fact that the stove heats not only the coolant, but also the smoke outlets. Directly during combustion, the heat generated is transferred to the heating radiators, and then the stove gives off heat for some time until it cools down completely.

- The heat exchanger can be built into an existing structure. In addition, even a cooking stove can become the basis of your heating system.

Model selection criteria

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

Relaxation in the bathhouse will be useful and enjoyable if the stove installed in it is chosen correctly and meets the necessary parameters. It is important to take into account the characteristics of the room and evaluate the technical capabilities of the stove. Only in this case will the heating of the air in the steam room be optimal and it will be possible to obtain an appropriate microclimate in the room./expert_bq]

What characteristics need to be taken into account when selecting a stove?

Power

This is the main criterion for selecting a model.

It depends on the volume of the steam room. Standard indicators are from 4 cubic meters / m to 18 cubic meters / m. Most models of Teplodar sauna stoves are suitable for such premises. When selecting power, you need to pay attention to the heat loss of the steam room, the most common of which are surfaces with high heat capacity (glass, tile), insufficient wall insulation, and operation in winter. Commercial baths require stoves with increased service life. Teplodar also has these in its assortment, they are marked with the PROFI icon.

The most powerful, created specifically for commercial use in steam rooms with a volume of up to 70 cubic meters, is the KomPar gas furnace.

Kamenka

The microclimate in the steam room and the rate of steam generation depend on its design features.

Among the Teplodar assortment, you can choose options with the following types of heaters:

Open means rapid heat exchange. The hot stones in it are in direct contact with the environment, the room warms up faster - only 1 hour and the steam room is ready. Stoves with an open heater can be of two types: classic - Sahara, Taman, Rus, where the stones are distributed at the top of the stove, mesh stove - Siberian cliff, Cascade, where the stones fill the entire height of the heater.

Open heaters are often chosen for Finnish saunas - the air in the steam room will be drier and hotter compared to saunas with a closed heater. It also performs a decorative function. Specially selected, beautifully arranged stones complete the laconic design of the stove.

A special type of open heater is the open ventilated one in the Rus and New Rus models. The models provide the ideal microclimate of a Russian bath.

Closed heater - a traditional type of heater for a Russian bath - models Laguna, Siesta. The heat lasts for a very long time, even after the fuel has completely burned out. Thanks to the internal water supply system, closed heaters will appeal to lovers of soft, moist steam - these are ideal conditions for steaming with brooms and comfortable long relaxation in the sauna. The peculiarity of stoves with a closed heater is that their design is more reliable and safe. It is almost impossible to get burned by hot steam from such a stove.

A combined heater is a design in which stones are placed in two heaters: closed and open (models Domna, Kuban). This method of laying stones allows you to independently choose the mode of steam supply and air humidity, so if desired, it is possible to arrange a Finnish sauna or Russian bath.

Firebox door

The Teplodar plant produces stoves with 3 types of doors:

Standard blind steel partition separating the combustion chamber from the room. This is a traditional option, which is presented in most modern models. Firewood can be laid from the steam room or dressing room. The latter option is more common: it is easier to use and the steam room remains clean.

Standard steel with a small viewing glass . Used in some modifications of Rus and Sahara stoves. Such a door is equipped with stoves with an extended fuel channel for loading firewood from the adjacent room.- Panoramic - has a purely decorative function. Through heat-resistant glass you can observe the live fire and monitor the fuel level. A number of sauna stoves from the Teplodar company have modifications with panoramic doors - models New Rus Panorama, Sibir Panorama, Sibirsky Utes Panorama Profi.

Fuel type

Sauna stoves are traditionally heated with wood. The smell of burning logs and the beautiful sight of a live fire encourage relaxation. All Teplodar sauna stoves are wood-burning, except for the gas model KomPAR.

Firewood is an economical, simple type of fuel that carries with it the traditional romance of a bathing holiday. But at the same time, this is a more complex way of lighting a stove - the wood needs to be dried, chopped, stored somewhere, constantly added to the firebox and the ash removed after burning.

There are also modern models of sauna stoves that use gas as an alternative source. In modern sauna stoves from many manufacturers, if necessary, a special gas burner and a special chimney are installed.

This feature is provided in all Teplodar sauna stoves, except for models with a panoramic door and Rus 9. Such stoves are connected to a gas pipeline or gas cylinder. This is convenient because you do not need to monitor the fuel level, empty the ash pan, and wash the bathhouse from soot and ash.

Important! Installation of a gas stove for a bath can only be carried out with the permission of the gas service and with the help of qualified specialists.