From the times of Ancient Rus' to the present day, the tradition has been widely in demand - a log bathhouse is quickly built and is environmentally friendly.

The performance properties of wood, especially natural logs, are very high. Let's look at them in more detail below.

Is the material suitable for a log steam room?

It is not only possible, but also necessary to build log baths , as they guarantee:

- maximum functionality;

- practicality;

- durability;

- provide an opportunity to gather with loved ones and friends in a warm, sincere atmosphere.

Coniferous trees are considered the best building material, as they emit unique resins and create a unique microclimate with a healing aroma. This wood practically does not crack due to temperature changes.

Deciduous trees such as birch, oak, aspen or linden are excellent for work. They also release elements and aromas that are beneficial to the human body.

The following types of logs are suitable for construction. Let's consider each type separately.

Chopped and planed

These are log houses of a standard shape, which are processed manually .

The top layer (sapwood) is carefully removed, and logs of different sizes in diameter are obtained, in their original form. The properties of reacting to external influences from outside and inside the building are preserved.

Minor roughness and knotiness are acceptable, the cost is inexpensive. It is difficult to assemble this material, since the logs have different diameters, which complicates the work of thermal insulation.

A detailed article about a bathhouse made from chopped logs is here, and from planed logs here.

Rounded

The logs differ from the previous ones in their beautiful, even appearance and size. They are processed on special machines, which additionally give the material a flat, smooth surface. The material becomes less resistant to negative influences, but this can be eliminated by using protective impregnations. This option is more expensive.

Full information about the bathhouse made of rounded logs is at the link.

Carriage

The log has a flattened appearance, is processed on both sides, gives minimal shrinkage and a slight appearance of cracks.

Logs with a diameter of 30 cm or more are suitable for construction; the buildings will be of high quality, warm, and durable. But options of 20-25 cm are possible; a smaller diameter will retain heat worse.

Large, thick logs with a large diameter crack faster and more often than others, but they look very impressive and rich, especially cedar ones. This wood has antibactericidal and medicinal properties and does not harbor insects. Young trees with an average diameter are most suitable for mass use.

Layout

Any bathhouse made from “cylinders” will look beautiful and impressive. The bathhouse with a terrace looks especially elegant, where you can relax after water treatments and enjoy the fresh air. Often, the planning of a terrace is provided for at the design stage, and its construction is carried out on a common foundation and under a common roof.

Two-story baths with a terrace or attic are especially popular. On the second floor you can arrange a recreation area with rooms for spa treatments or a guest bedroom, and on the terrace and veranda you can place a barbecue or grill. Such baths are usually part of entertainment complexes and are designed for high traffic and regular use. It is not uncommon to find elegant gazebos, swimming pools, and various decorative elements on the territory of a bathhouse complex.

The parameters of baths made of calibrated logs may vary. Standard projects involve a main structure of 4x6 m. A terrace or veranda is usually made 3x4 m - the same as a kitchen. Large buildings can reach dimensions of 5x5 or even 6x6 m with a 3 by 4 dressing room. Usually an extension is made measuring 1.5x4 m, which can be used as a rest room.

Designing bathhouses with a swimming pool is a complex and time-consuming process than creating conventional projects. Creating such a project involves taking into account many factors: the appearance of the building, its shape, type of foundation, location of utility networks, waterproofing of walls and much more. The pool can be located inside the bathhouse or outside. In the latter case, heating is usually used.

Options for complexes with an outdoor pool are considered a more economical option and are not so difficult to implement. The pool can be located under the same roof as the bathhouse and have common utilities with it. However, in this case, a large area will be required to accommodate all the buildings, and the volume of excavation work will be several times greater.

Rules for building a steam room

In the 21st century, the requirements for the construction of a bathhouse have changed dramatically. Now a dressing room and a steam room are not always enough; relaxation rooms, billiard rooms, showers and toilet rooms are very important. The total footage and amount of materials will depend on how many floors and rooms there are in the bathhouse, what kind of design and layout it is.

The best wood is considered to be that harvested in the northern regions of Russia, and in winter, since during the winter season it has the lowest level of humidity.

When building a log bathhouse, some features should be taken into account :

it is better to use logs with special protective impregnation against rotting, fungus and parasites;- raw wood will require a longer period of shrinkage - only after this are doors, windows installed and finishing done;

- the cracks must be sealed hermetically to retain heat in the room as much as possible;

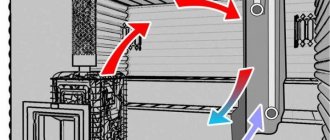

- the creation of ventilation and installation of the stove should be entrusted to a professional - this guarantees safety in operation for decades.

To build a bathhouse, you need to choose the right location on the site ; it depends on the building codes of SNiP, which take into account:

- communications (underground);

- the distance from buildings and neighbors’ plots is no closer than 8 m from other buildings, since the bathhouse is a fire hazard;

- distance from the roadway and water bodies - at least 5 m.

Many people plan in advance to landscape the area where the log house will be located, creating the most cozy and comfortable corner.

The most popular, inexpensive wood options are spruce and pine. Experts recommend giving preference to northern tree species; they absorb less moisture, unlike southern varieties.

It is necessary to start construction after the purchased “timber” has rested and “inhaled” for 25-30 days . The log house is assembled using the technology of cutting logs “into a paw” or “into a bowl”. The first option is cheaper, easier to assemble, provides a larger area, but requires additional insulation and external finishing. The second is durable, saves heat as much as possible, is more labor-intensive, expensive, but does not require external finishing.

Requirements for structures

Requirements for the location and construction of wooden baths were invented to make the building safe for visitors. They are spelled out in several government documents:

- SNiP II-25-80.

- SNiP 2.01.07-85*.

- SNiP 2.02.01-83*.

- SNiP II-L.13-62.

Requirements for distance to other objects and buildings:

- residential building - 8 m;

- trees - 3 meters, bushes - 1 m;

- natural, artificial reservoirs - 25 m;

- neighbor's plot - from 1 m;

- wells, wells - from 12 m;

- forests - 10–15 m;

- roads - 6–10 m.

These are average standards, errors are possible.

Fire safety requirements:

- Electrical appliances inside the bathhouse must be grounded.

- There must be a working fire extinguisher in the rest area room.

- The walls around the stove should be covered with reflective screens.

- A metal sheet must be fixed to the floor in front of the combustion chamber.

- The stove should be located above the floor level at a height of 12 cm.

- Do not use flammable mixtures or chemicals to light stove equipment.

The bathhouse should be located on a hill and not create smoke in residential buildings when the stove is fired. You can install an electric oven.

Forest (Photo: Instagram / makc_krupskiy)

Calculation of the amount of wooden material

To make a correct calculation, you need to know the length, height and width of the load-bearing walls, and all internal walls and partitions - this is the first thing. The second is the parameters, dimensions of the logs (thickness, width).

For example , for a log house 3x6 m3 (five walls) - two walls of 6 m each (12 m.) and three walls of 3 m each (9 m.). The standard height is 3 m, and the diameter of the log is 30 cm.

Calculation:

- The length of one crown is considered to be 12 m + 9 m = 2 1 m.

- Calculate the number of crowns in the log house. 3 cm is subtracted from the diameter of the log (to make a groove). The height of 300 cm is divided by the resulting figure of 27 cm, resulting in 11 rows up.

- The number of logs for a log house - the number of crowns and the length of one crown are multiplied. 11 x 21 = 231 m. This total length is divided by the standard log length of 6 m, rounded up. 231:6=39 logs in total will be needed to build a bathhouse 3x6 m3.

To find out how much this amount of timber will be in cubes, you should refer to a special table - the round timber cubes. In this example it will be 20.3 m3.

What distance should be from the bathhouse to the fence, house and other objects

February 21, 2022 Suburban construction 7,

When building dachas and suburban areas, owners focus exclusively on their own desires and budgetary capabilities.

When determining the size of a house or arranging outbuildings, neither their purpose nor the distance between buildings is taken into account. And the opinions of neighbors are rarely considered at all

But all this is fraught with risks - claims may arise from fire authorities, and neighbors are always ready to start legal proceedings.

Therefore, when determining the places and methods of location of the bathhouse on the territory of the dacha, several points must be taken into account:

- The high fire hazard of this structure,

- The need for water supply, sewerage and drainage.

Determining the minimum distance between a bathhouse and structures on an adjacent site

To determine the required safe distance between the bathhouse and other buildings on the territory of the dacha, you must be guided by SP 53.13330. This document was adopted on the basis of SNiP 2.07.01-89 “Urban planning. Planning and development of urban and rural settlements.” The presented regulatory document establishes the following requirements for development planning:

- the distance between structures built from non-combustible materials (concrete, stone, reinforced concrete, etc.) is 6 m according to the standards,

- the minimum free space between a concrete or stone building and a structure made of non-combustible building elements with wooden floors, which are protected by special non-combustible or low-combustible materials, is 8 m,

- if one building is made of non-combustible materials and the second is made of wood - at least 10 m,

- territorial gap between two buildings made of non-combustible materials with wooden floors – 8 m,

- mutual distance between structures with wooden floors and a log bathhouse is 10 m,

- between two log baths (wooden buildings) the distance is 15 m.

The presence of an already constructed bathhouse on the adjacent site clearly requires you to comply with the requirements for fire breaks. Such safe distances within the site are not differentiated and are fixed at the minimum possible level of 8 m.

How to eliminate shading of the neighboring territory

Compliance with fire safety standards is as important when designing buildings as taking into account the distance to fences between estates. The main condition is to minimize shading of the area adjacent to yours. Therefore, the rules provide for the need to arrange a bathhouse at a distance of 3 m from the fence of a neighboring estate. But the distance to the boundaries of the site adjacent to external roads or driveways is determined to be 1 m.

Minimum distance from the drainage trench to the fence of the neighboring plot

To operate the bathhouse, it is necessary to provide water drainage from the sewerage system. The requirements that must be taken into account in this case are described in SP 53.13330.2011. If the drainage trench is filled with a filter-type mixture consisting of gravel and sand, then it should be 1 m away from the fence of the neighboring house.

Distance from the shore of the reservoir to the bathhouse

If the building site is located near a reservoir, then during construction the requirements of the Water Code and the Construction Rules in conditions of high groundwater levels should be taken into account. The first document established the distance of the bathhouse from the reservoir by 20 m, and the second document provided for the location limits of 20-30 m from the shore.

The legislation also defines requirements for ensuring freedom of access to reservoirs, and therefore the width of the coastal zone cleared from structures of any type is 20 m. If you want to build a summer house with a bathhouse on an area adjacent to small reservoirs up to 10 km long, then the width of the free the coastline will be 5 m.

Compliance with the minimum distances for placing structures is important. This is due to the risk of administrative fines, problems with neighbors, as well as basic personal safety requirements

The larger the territory, the more opportunities the owner has when designing the placement of buildings on it

However, even in this case, it is important to choose the right material for the construction of a bathhouse, taking into account the distance between buildings on the site itself

What distance should be from the bathhouse to the fence, house and other objects

Where to build a bathhouse on the site and what distances should be maintained so as not to violate the norms? Standard distances from the bathhouse to the fence, house, site boundary and other objects.

How to build a sauna with your own hands?

Construction work should be carried out in stages, following the instructions.

Project

The layout, number of floors and dimensions of the bathhouse structure are determined - individual solutions or a choice of ready-made turnkey projects are possible. Based on the selected drawing and calculations, materials are prepared.

Laying the foundation

For log structures, a reliable, durable concrete strip foundation is created. A pile option is possible depending on the composition of the soil. Ventilation vents are provided around the perimeter.

Installation of the first crown and walls

The foundation is covered with waterproofing, for example, roofing felt, and the wood is pre-treated with antiseptics. The logs are carefully laid crown by crown to the desired height and allowed to dry. The inter-crown insulation can be anything - from modern materials, or natural moss.

The logs should be laid with the north side outward, and the south side inside the log house. You can see from the annual rings on the cut that they are thinner on the north side, and the tree on this side is more resistant to the negative influences of nature. This extends the service life of the building significantly.

Roof

Often, for a small bathhouse, a pitched roof is chosen. This budget option is easy to install.

A gable roof of a more complex design is used in the construction of spacious, large options.

For work you will need:

- wooden beams;

- lathing boards;

- the covering can be anything - tiles, slate.

Bake

The best type is a brick oven; it guarantees maximum thermal properties. The walls of the stove should not come into contact with the walls of the bathhouse . You can choose ready-made models (made of metal), wood-burning or electric models.

Insulation

The cracks between the logs are carefully insulated with tow, moss or flax with sealant. In a completely finished log house (according to the drawing), openings are cut and window and door frames are installed.

To preserve heat, it is advisable to make the doorway at a height of 30 cm from the floor, and the window no higher than 100 cm. The floor is laid in a continuous manner, or a strip covering with slots is created for water drainage. Concrete screed guarantees up to 50 years of service compared to wood (up to 10 years); tiles are also durable.

Finishing of external walls and partitions

External finishing for rounded wood is not necessary, but chopped round timber requires decoration, but only after complete shrinkage. Each crown is aligned relative to the previous one. In finishing they use:

- stains;

- antiseptics;

- varnish coatings.

If desired, use siding or brick decoration with insulation. For interior decoration, lining, edged boards, and varnishes are used.

After removing the top layer during rounding, the number of cracks on the logs decreases - this increases the thermal insulation of the material.

Tip: Drawing up a goal tree

Construction is a rather complex and labor-intensive process. Its implementation requires special skills. For proper organization - drawing up a clear plan of sequential actions. This is precisely what is suitable for this purpose, nothing more than drawing up a tree of goals

This is a kind of set of ideas, which is distributed among levels depending on the degree of complexity, importance

This planning method is considered very effective. The “trunk” of the tree is the main task, the “branches” are the tasks of the levels below.

As a rule, a tree is depicted graphically. This allows you to clearly understand your goals and determine methods for achieving them.

Also, using such a graph, you can determine the approximate time frame for achieving the result.

When compiling a goal tree, we are guided by the following principles:

- Takes into account needs and resources. The goal you strive to achieve is not always achieved through the available capabilities. At this stage, you can perfectly structure your actions and evaluate the resources needed for a solution;

- Specifics. Goals must be clear, precise, and specific. Here the parameters of achievement and the time for implementation of the plan are determined;

- All subgoals, when completed, must solve the main task;

- The main task is divided into secondary ones. Or vice versa: several additional goals merge into a single one.

Important! When compiling a tree, you should always choose an option, the execution of which will require the use of available resources and their rational use.

Advantages and disadvantages

Natural wood has an undeniable, beautiful appearance, guarantees safety and durability. A log bathhouse has the following undeniable advantages :

minimal thermal conductivity - retains heat in the room for a long time, warms up many times faster in winter compared to a brick building;- excellent air circulation - condensation does not accumulate, steam “flows” freely;

- sound insulation – absorbs extraneous noise as much as possible, including from the street;

- wood is easy and quick to process - a log house is created in a short time, exclusive options are possible (to order), both in project development and in finishing, carving;

- environmental friendliness, being in a log bathhouse is not only safe, but also useful - pine, cedar and other wood release beneficial essential substances and resins into the air (the steam becomes medicinal);

- affordable price compared to brick construction;

- wear resistance - the structure, if all technological processes during installation are followed, will last for many decades, up to 50 years or more.

a log bathhouse ; additional ventilation is a big savings. Facade cladding and interior finishing are also not required; the log house looks impressive, status-bearing and noble. The variety of different ready-made turnkey projects significantly reduces the construction time of the structure.

But you should not forget about some disadvantages

- a fresh log house needs time to shrink - this period can be shortened by rounded, dried logs;

- wood that is too dry may crack;

- in humid climates, poorly processed logs are susceptible to mold and mildew;

- fire hazard.

If you carry out construction work, following the instructions, taking into account all the features, and choosing the right type of high-quality wood that matches the climate zone, then the log house will last for many decades.

Finishing work in a bathhouse made of rounded logs

You can begin interior decoration after caulking the walls and laying communications. It is necessary to start installing floors , which are most often installed on logs, although in a washing room it would be more convenient to use a concrete screed with the possibility of laying ceramic tiles or other material with similar characteristics.

The walls of the bathhouse do not require special finishing, since the wooden frame itself has a very aesthetic appearance. But to protect wood, you can use varnish or colorless impregnations, but this is true for all rooms except the washing room and especially the steam room.

In the washing compartment, you can protect the walls and ceiling with moisture-resistant decorative materials, but be sure to take care of the problem of vapor barrier and moisture removal. To do this, it is necessary to install special ventilation gaps between the rounded log and the finishing coating.

Things are different in the steam room - since coniferous wood is often used to build walls, which actively releases resins that can slightly spoil the appearance of the walls. Therefore, it is better to sheathe the steam room with clapboard made of hardwood , for example, linden, alder, oak, etc.

In the event that the diameter of the rounded log for the construction of the bathhouse was selected correctly, then there is no point in dealing with the external decoration of the walls - such a structure has its own charm, and bathhouses look especially impressive if the ligation of the crowns is done “without remainder”, although in this case , more expenses will be required for the purchase of material, but the corners will be warmer , since cold bridges will not form at the joints.

How much does it cost: prices in the Russian Federation

In our country, it is possible to build an excellent, high-quality bathhouse in a short time in any region. Average prices , taking into account the diameter of the log, size, number of floors, layout and cutting are as follows:

- budget option 3x3m - from 80 thousand rubles. (chopping by hand), from 95 thousand rubles. (chopping into a bowl);

- sizes 3x4m or 3x5m are slightly more expensive by 7-15 thousand rubles;

- 3x6m – from 105 thousand rubles. up to 120 thousand rubles;

- 4x6m – from 114 thousand rubles. up to 132 thousand rubles;

- 5x6m, 6x6m differ little in price - from 120-135 thousand rubles. up to 140-150 thousand rubles.

Cedar logs have the best resistance to moisture, the highest thermal protection, and healing properties, so they are expensive; larch is also considered expensive for its super strength. And pine, spruce, aspen or linden are cheaper.

Log houses made of rounded logs will cost more:

- 2x4m – from 255 thousand rubles;

- 4.6x5.5m – from 550 thousand rubles;

- 5.5x7m, 2 floors. – from 770 thousand rubles.

The choice of materials for finishing and its delivery to the installation site also affect the total cost.

Determining the quality of wood for logs

But the quality characteristics of logs from different woods are not the same. That's why they differ in price.

Thus, most baths are built from coniferous logs - spruce or pine. They are inexpensive and have many advantages. That is why the best wood for a bathhouse is from northern coniferous species, which has a dense structure and does not change its properties due to high humidity or high temperature. Ideal in this regard are pine from the Baltic Sea and Canadian spruce. In second place are high-quality alder, aspen and linden wood. And a self-built bathhouse made from aspen or larch logs will last for 100 years, but it will also cost more - because the logs of this species are very strong, and this strength only grows over time.

By the way, all production of wooden building materials in Russia is concentrated in the northwestern regions, where there is an excellent raw material base. And today, quite a lot of different companies and intermediaries of manufacturers are engaged in the sale of these products - you can even order everything you need via the Internet. It is only important to draw up an agreement with the contractor, which will indicate in black and white the type of wood, its moisture content, length, type of groove and method of drying. And, if you have the opportunity to look at the proposed wood in advance, you should pay attention to the following characteristics that indicate quality:

- Low heat capacity

- Light or dark yellow tint of the log surface

- Pleasant soft smell

- Good sound absorption

- No blue spots on the cut

- Low thermal conductivity

- There are a small number of knots that sit inside without gaps - if there are any, it means the core is rotten.

- Resistance to splitting

- The cut of the log has a hard surface

The core of the log itself should be exactly three-quarters of the cut and at the same time have an even dark shade.

But what if the arriving logs look damp?

The reason for their dampness may be insufficient drying. In this case, it is better not to treat them at all - except with a transport septic tank. If this has not been done in advance, what should be specified in the contract. After that, you need to create a maximum ventilation mode. After all, if this is not done, the entire structure may shrink in the future - and longitudinal cracks will appear.

Photo

What kind of baths can be built from logs? Photo below:

Safety

Safety for a bathhouse is a paramount issue. Wood, stoves, constant exposure to high temperatures often lead to fires. The main reasons are contact of the chimney with wood and improperly installed electrical wiring. To avoid contact, it is recommended to tile the stove. The wiring must be used with asbestos insulation and run along the surface of the wall. Switches and sockets are not installed in the steam room; the lamps are protected by special shades. Sockets in dressing rooms are equipped with special covers.

If we take into account all the mistakes traditionally made by builders, the bathhouse will last a long time and safely.

COMPARATIVE CHARACTERISTICS

| Characteristic | Rounded | Chopped |

| Appearance | The surface is flat and smooth, the shape and width of each log is the same. | The width and shape differs in each log, the surface is rough and uneven. |

| Diameter | The entire length of the log is the same, not exceeding 320 mm. | Different. The choice of sizes is quite wide, up to 520 mm. |

| Assembly | Due to the identical diameters and smooth surface, it is quite fast and simple. | Complicating the process due to different-sized logs. Requires additional skills and professionalism |

| Thermal insulation | The tight fit ensures high insulating properties and minimal heat loss. | A large number of gaps reduces the insulation characteristics. To live in a log house on a permanent basis, additional insulation is required. |

| Production | Mechanical. High production speed at the expense of loss of some protective properties. | Manual. The protective layer remains intact, but the production time increases. |

| Protective layer | Gets lost. Treatment with additional protective agents is necessary. | Saved. A basic impregnation against moisture and insects is sufficient. |

| Shrinkage | From 0.5 to 1.5 years. The result is 7-12%. | From 0.5 to 1.5 years. The result is 7-12%. |