28.10.2012

The interior decoration of the bathhouse, and

the lining of the walls of the steam room in particular, is of great importance.

Without doing this, you cannot count on the durability of the structure itself. After all, heat loss, especially in a steam room, will not add to the pleasure of visiting it. Therefore, the presence of thermal insulation of the walls is a necessary condition when building a bathhouse with your own hands. All this fully applies to non-log buildings. But what to do if the bathhouse is a log house, the material of which is an excellent natural heat insulator? Let's try to figure this out together.

1.Rates and finishing work calculator for 2021

Check out the prices of facing works. Prices for Moscow and the Moscow region are shown in the table. If you have any questions about the project and payment methods, please contact the manager by phone. He will tell you about everything in more detail. Also read reviews about the company. Contact phone number –

| Name | Unit change | Price in rub. |

| Caulking of a log house made of rounded logs | m.p. | from 75 |

| Sanding walls made of rounded logs | m² | from 300 |

| Thermal insulation (5cm) | from 120 | |

| Installation of sheathing | from 200 | |

| Steam and waterproofing | from 80 | |

| Finishing the bathhouse with clapboard | from 400 | |

| Finishing the bath with ceramic tiles | from 1500 | |

| Finishing the bath with porcelain tiles | from 1700 | |

| Bathroom finishing with clinker tiles | from 1800 | |

| Finishing the bath with terracotta tiles | from 1900 | |

| Finishing a bathhouse with a block house | from 460 | |

| Finishing the bathhouse with siding | from 300 | |

| Finishing the bath with imitation timber | from 400 | |

| Finishing the bath with salt stone | from 8500 |

Use the built-in calculator to find out the cost of finishing a bath.

Work price RUR/m²

Sum:

0₽

What else to finish?

Large public baths, starting from Ancient Rome, were and are now often finished with mineral materials - stone, tiles. They are definitely not suitable for a small bathhouse: as the size of the building decreases, per unit of its volume there is an increasing area of external surfaces, and with it heat loss. Then, to make a stone bath breathe, it needs high, from 4-5 m, ceilings and well-designed ventilation and hot air supply systems; The design of the Roman baths still fascinates engineers and builders.

Have you been to the hammam? How high is it from the heels of the person standing in pairs to the lowest point of the ceiling? If less than 4.2 m, then what kind of equipment is hidden in the technical premises? How much does it cost, consume fuel and electricity? In a private household, the interior decoration of the bathhouse should, without alternative, be wooden. This makes it difficult for it to achieve proper hygiene, but there is no other way to install a healthy sauna with dimensions less than approx. 12x16 m no.

By cooperating with us you get

Guarantee of meeting deadlines

- Delivery of the project is always on time

- In case of delay, we incur a penalty of 3% per day

Transparent, fixed estimate

- No hidden extra work

- You pay only for what you need, and you choose what you need yourself!

Daily photo and video reports

- Work progress reports via WhatsApp or email

- You will be in the know, even if you cannot be present on site.

We consult clients free of charge, coordinate a home visit, carry out the necessary measurements and calculations, draw up an estimate, and begin work after concluding a contract. During the implementation of the project, we make detailed photo reports, record videos, and send them to clients. This way, customers will be aware of what is happening if they cannot be present on site during construction work.

Expert recommendations

In order for a log bathhouse to serve its maximum service life, it is important to properly and carefully maintain the premises.

- Natural ventilation of the premises must be organized. Fresh air will help quickly dry wooden materials that are most exposed to moisture.

- In the washing and steam room, after all procedures have been completed, cleaning must be done (everything needs to be swept, washed, put away) and then thoroughly ventilated. If possible, it is advisable to move all furniture outside.

- To provide additional protection, wooden materials periodically need to be treated with protective impregnations. They will prevent rotting, the appearance of fungi and mold. But the compositions must be intended specifically for the bath, without containing harmful and dangerous substances in their composition.

Any finishing materials for the bath can be used at the request of the owners. But the main thing is that they are natural, safe, moisture-resistant, not afraid of temperature changes and retain heat well.

How we are working

Leave a request

We will contact you and give you a free consultation

We coordinate the departure

Our specialist will visit your site to make the necessary calculations and take measurements.

Commercial offer

Based on the data collected by a specialist, we prepare an estimate for you and send it for your approval.

We conclude an agreement

If you are satisfied with everything, we conclude an agreement and carry out all the necessary work.

Each client can receive a guarantee certificate valid for at least 2 years for a turnkey project of any complexity. We hold promotions where we offer various services on favorable terms and guarantee transparent cooperation. You can view the company’s portfolio in the field of construction on the website or on social networks. Contacts - +7 (495) 258-93-97

3.Types of finishing of a turnkey timber bath

There is an internal and external lining of the bathhouse made of logs. It is carried out at least six months after the completion of construction of the facility. During this time, shrinkage of the wooden structure occurs. Afterwards, repeated caulking is carried out - the process of processing log houses (the first rough caulking is done when assembling the log house) and cladding the house.

3.1 Internal

A bathhouse made of rounded logs is covered inside with various natural materials that are resistant to moisture and high temperatures. Most often, lining or tiles are used, less often salt stone.

Inside the bathhouse there is a dressing room, a steam room, and there are also projects with a shower room, a terrace, an attic, and a staircase leading to the second floor. Each of these premises has its own requirements for safety and environmental friendliness. The building materials must match them.

It is a universal wooden board for cladding a log house. Made from deciduous and coniferous wood:

- aspen or linden;

- alder, ash;

- cedar;

- larches;

- pine, spruce or fir.

The material covers all surfaces of the house and doors. In the steam room, panels made of deciduous trees (aspen, alder, ash) are installed. They are smooth. The steam room is not covered with coniferous material. When heated, toxic resins are released from it.

For covering the dressing room, attic and terrace with doors, choose any type of lining. These rooms are not heated.

Used to cover floors, ceilings and other surfaces of bathhouses, as well as Russian stoves that can be built inside. It is durable, tolerates high air humidity, sudden temperature changes, and lasts a long time. A wide range allows you to create any pattern on the flooring of your home. Oriental tiles will fit perfectly into a Turkish bath.

The following slabs are chosen for cladding the house:

- terracotta;

- porcelain stoneware;

- ceramic;

- clinker

Ceramic is considered the most popular for a shower room. It is easy to clean, inexpensive, and lasts a long time.

Designed for interior lining of bathhouses. Does not deform when exposed to high temperatures. Usually it is a briquette or pebbles. When heated, it releases particles that create a marine microclimate and disinfect the air in the house.

The material has a beautiful pattern, textured surface, and useful properties. Most often, Himalayan salt is used to make it. The material is installed in a room with air humidity of no more than 55%. They can be used to make one or more walls in a log house. The only negative is the price.

3.2 External

For the exterior cladding of a house, it is best to order imitation timber, block house or siding. They will help to insulate the facade and foundation of a log house.

A type of pine lining for covering the frame of a house. It lasts a long time, is easy to install, and keeps the house warm. Consists of natural wood and has a beautiful appearance. Such cladding of a house will last at least 30 years. The hollow located in the center increases its service life. The house is covered with middle or high class material.

There are several types of imitation timber. Thermal one has a darker rich shade, and the brushed one resembles an aged board. Both options will give the log house an original appearance from the outside.

It is a wooden panel made of coniferous wood with a semicircular front side. The back surface of the block house is quite flat with two longitudinal grooves. They improve the quality of the ventilation system of a log bath. The panels are designed for large surfaces of a log house. The best length of material is 3 m.

The advantages of a block house are durability, tolerance to temperature changes, compliance with environmental standards, waterproofing, simple installation, light weight, low price. There are no cons for the home. Problems can only arise due to a violation of the technology for installing wooden panels, so it is recommended to contact professionals.

Decorative panels for lining a log bathhouse, standard size - 22x125 cm. Siding can be metal or vinyl, available in 10 colors. It is mounted in a horizontal position with a distance of 20 cm from the foundation of the house.

Siding protects the house from precipitation and is resistant to fading and temperature fluctuations. Does not release toxins and does not cause inflammation. Its main disadvantages include the need for grinding, poor ability to pass air, and the high price of fixing structural elements. This material is used to cover a house made of profiled timber.

What is important to know about wood quality

In addition to the type of wood, it is important to consider the quality of the material when purchasing.

Its operational characteristics are determined by the class:

Extra – the highest quality, without knots or defects.

A - also has impeccable qualities, but it can show a texture typical for this breed.

B – small knots and pronounced patterns are possible.

C is the lowest quality grade with noticeable knots and uneven texture.

For finishing steam rooms, it is optimal to use Extra, A-class lining and a mixture of A and B. This is due to the fact that large knots with overheating and constant changes in humidity can lead to deformation of the entire canvas and the formation of traumatic chips and splinters.

Class C lining can only be recommended for dressing rooms, rest rooms and other auxiliary premises.

If the premises are sheathed with edged boards, it is also worth considering the quality of the material. In the steam room and washing room, it is recommended to use extra-class and first-class boards. Second grade material has knots that will not withstand temperature changes. This board can be used to decorate rest rooms.

The service life of wood siding and the preservation of its remarkable appearance will depend on proper treatment with protective solutions and periodic maintenance.

Stages of finishing a log bath

First, they measure the area of the premises, calculate the amount of materials, and create a project. After completion of construction and shrinkage of the bathhouse frame, the project begins:

| 1. Insulation of a log bath. The surfaces of the house are sanded and caulked with penofol or polypropylene. | |

| 2. Installation of slatted sheathing to ensure ventilation of the log house. The slats are installed at a distance of 70 cm from each other, fixed with galvanized or stainless steel screws. | |

| 3.Installation of vapor barrier. A vapor barrier film is laid on a log house with the rough side. The surface of the overlapped joints is overlapped and insulated. | |

| 4.Installation of thermal insulation and waterproofing. A thermal insulation layer (mineral or basalt wool) is applied to the surface of the house, and then a waterproofing layer. | |

| 5.Finishing the log house. A log bathhouse is covered with the selected material. The outside of the house can be subjected to standard or sandblasting and coated with a protective compound. |

5. Mistakes when covering the steam room

The main room in the bathhouse is the steam room. When covering it, numerous mistakes can be made:

- The lining is installed on foil without a ventilation gap between the lining and the bath. Steam penetrates through it and settles on the foil in the form of drops. This leads to rotting of the lining on the back side. Thanks to the free space, the drops will be blown and dried.

- Immediately attach the lining to the timber wall. After building a house, the timber can gradually settle, and the board will prevent this. As a result, the log can push through the lining, it will bend inside the house. There is also a possibility that the lining will be stronger than the log and will hang on it, creating blown cracks.

- A wooden floor is laid in the steam room, which begins to rot due to water penetration. Instead of wood, porcelain stoneware is usually used - a mechanically resistant material with low moisture absorption.

- The vapor barrier in the house is not done correctly; the joints are taped with transparent tape instead of metallized tape. Subsequently, it turns out to be leaky, and cracks appear in many places in the house.

- Do not put a window in the steam room, which can provide additional ventilation and natural light. A plastic window is suitable for a steam room if the temperature inside does not reach 90-120°C.

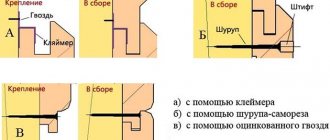

- The sheathing is attached using the open method. This results in nail heads sticking out, which can cause burns or scratches during cleaning. It should be installed in a closed manner in the house.

The company Artel and S will help you avoid this. We develop an individual bathhouse project to order, follow installation technology, use modern equipment

The popularity of red cedar and abash wood finishes

Red cedar is quite popular today. Of course, this is a very expensive tree, but it is worth it. A bathhouse, which is decorated with red cedar, can always be recognized even with your eyes closed - only by its unique aroma.

The healing properties of this wood are widely known. In such a bath you can not only relax perfectly, but also calm your nervous system and gain vital energy. The pinkish tint of cedar will add some variety to the usual wood finish.

For passionate connoisseurs of the exotic, we recommend covering the walls of the steam room with African abash wood. The unique porous structure of this palm tree gives the wood extremely low thermal conductivity. Shelves made of this material will remain slightly warm even at very high air temperatures.