The dream of every owner of a country house or summer house is to have a sauna or bathhouse on his small plot of land. The bathhouse is a wonderful relaxation, the best place to chat with friends. The bathhouse cures many diseases, and is popularly considered a real cure not only for colds, but also for other ailments. It relieves stress and makes you forget about annoying worries and problems. Therefore, people who decide to build a bathhouse first of all think about a beautiful interior, because they want to feel free and comfortable in it.

In a Russian bathhouse, the stove is heated with wood, which means that it must be prepared in advance. The owner provides a special place for storing firewood. This could be a barn, a fence behind the house, or a woodshed. This is for the main fuel supply.

But sometimes there is a need for several logs next to you during bath procedures. For such cases, it is advisable to have a special firewood rack for the bath . We must try to make it not only useful, but also an attractive thing that will help enliven the room, create comfort and a favorable environment for relaxation and pleasant time with guests.

Materials for woodshed

For production use:

- wood - boards, round timber, beams, slats;

- wood materials - plywood, OSB, chipboard;

- metal;

- brick;

- blocks;

- roofing materials;

- cellular polycarbonate.

Any available materials, construction pallets, obsolete utensils or furniture can be used. There are no restrictions on their use, but for outdoor conditions, moisture resistance is an important criterion.

Tree

This is the most affordable material for making a woodcutter with your own hands. It is easy to process, and with the help of mechanical fasteners you can assemble any spatial structures.

Wood combines perfectly with any other materials for country house construction. To be used outdoors, lumber must be treated to prevent rotting. They can be coated with waterproof impregnations, paints, and stains. For decoration, forged elements, decorative grilles, and clapboard cladding are used.

Metal

A durable, strong woodshed can be built from metal profiles, pipes, corrugated sheets, sheet metal, and fittings. The frame is assembled using welding, bolts or rivets. The outside is sheathed with boards, metal mesh or any other materials as desired. Metal parts are treated with a primer and metal paint.

In the wall-mounted version, the back part of the woodshed is already there. Racks or walls are installed on the sides, and the top is covered with roofing material sloping away from the wall.

Wall-mounted forged firewood

Brick

The brick woodshed is a solid, solid structure. Most often it is provided as part of a complex of an oven, barbecue and barbecue in summer kitchens or gazebos.

Brick is durable, not afraid of rotting, corrosion, and fire. But it is quite heavy, so it requires a solid foundation. It can be poured from concrete, laid out from blocks or bricks.

Polycarbonate

The woodshed made of cellular polycarbonate looks elegant and harmonizes with the surrounding country houses. The material protects well from precipitation, preventing the wood from getting wet. It can be transparent or colored and can be combined with any building materials.

For the installation of firewood, sheets with a thickness of 4-6 mm are used. They are attached to a frame made of wood or metal using roofing screws. The edges must be covered with protective profiles to prevent moisture from entering the cells and rapid flowering.

Non-standard solutions

The woodshed can be built from unusual materials:

- wooden barrels and other used containers;

- unsanded logs;

- sewer concrete rings.

The barrels are placed on their side on a non-rotting stand and firmly secured. After treatment with antiseptics, a simple but convenient woodshed is ready.

An interesting option is a woodpile for firewood made of a concrete ring, imitating the cutting of a huge round log. Manufacturing comes down to installing the structure in a recess and further decorative finishing. To imitate bark, textured plaster with a cement binder is used. The relief is created using a spatula, a roller attachment or fingers. After the solution has set, paint the surface with facade paint. To protect the ends of the rings from slanting rain and snow, you can install shields made of boards or moisture-resistant plywood.

Scandinavian woodcutter

The Norwegian-style firewood box looks very unusual and beautiful. This is a small house with plank walls and a squat, wide roof. The originality of the building lies in the fact that it is a frameless structure.

The boards are laid like crowns, that is, with a remainder. Cuts are made in the end parts of the boards. Each element rests on 2 neighboring ones and is rigidly clamped with a locking connection. There are gaps between the boards for ventilation, which creates a favorable conditions for drying even a large amount of firewood. The roof is made of lightweight material, such as flexible tiles.

In Scandinavian countries, not only utility blocks are built in a similar way. Not very nice objects are hidden in them, for example, transformer booths.

Firewood: why we need it and where to store it

To organize a good rest, it is advisable to have firewood, but for heating it is simply necessary. Still, country life most often focuses on them. There are several arguments in favor of this heating method:

1. lack of electrical and gas communications in the area where the dacha is located,

2. heating with wood is one of the more accessible and cheaper heating methods,

3. firewood is a necessary attribute of a real bathhouse, therefore lovers of the ancient method of rejuvenation always have the necessary supply of firewood,

4. live fire is always beautiful and adds coziness to the room.

A live fire will add coziness to the room

All these arguments contribute to the fact that heating a country house with wood is becoming one of the most popular methods.

But you can’t buy an armful of three lozins in a supermarket, and where is this super store if you are in the middle of a summer cottage? Therefore, they stock up on firewood for a long time and store it on the site for long-term storage. But not all wood is good for a fire; freshly cut trees generally need to dry well, therefore, you need not only to have a place for storage, but to create conditions for the firewood to dry sufficiently.

A woodcutter at the dacha will solve the problem of storing firewood

For these purposes, woodsheds for summer cottages are built on a country plot. These specially constructed structures must meet the following requirements:

1. the design must allow for the placement of a large volume of firewood for storage; when neatly packaged, it must be easily accessible for use;

2. when storing firewood, there must be a constant flow of fresh air necessary to dry the raw materials;

The woodshed must have good ventilation

3. The woodshed must have a canopy that well covers the firewood from precipitation;

4. During construction, try to erect obstacles in the path of sunlight. Under the influence of ultraviolet radiation, wood changes its structure and subsequently burns very quickly under the influence of fire, which is undesirable for a stove;

Try to protect the firewood from direct sunlight

5. The design of the firewood shed must fit into the landscape created on the territory of the dacha, not introduce disproportions and not disrupt the harmony of the space.

Making firewood

Do-it-yourself firewood for a dacha is very easy to do - even someone who has little experience in construction can do it.

First of all, you need to decide on its location - it should be level, but with a slight slope so that water can drain from it without outside help.

It is necessary to outline the perimeter of the building and dig 4 holes in its corners where the base of the building will be located - these can be metal pillars or beams.

The bottom of the pit is lined with a sand cushion on which the base is placed. The remaining space can be filled with crushed stone, or filled with mortar - at your discretion.

After the foundation, you need to build the frame and walls of the building. For them, you need to strengthen several boards from below along the entire length of the future firewood shed. The boards must also be diagonal to make the structure stable.

Metal objects must be welded to the posts and secured using corners. This will be the frame onto which the walls are then attached. Almost any wall material is suitable.

If the material for the building is wood, then you can use boards or slabs; if metal, then clapboard and planks.

The walls should not be solid - there needs to be room for air circulation and ventilation of the firewood.

If you are going to make a firewood shed out of metal at your dacha, then cover it with a chain-link mesh, and you can use corrugated sheet metal or slate as a roof. It is best if it is single-pitched.

When building, make sure that the water rolls back and not forward of the structure.

If the roof is made of wood, select beams of different shapes for it: those located in the front should be higher than the back ones.

This is your firewood. As you can see, building it is not at all difficult. This design can be used to light a bathhouse and other everyday needs.

When you put logs in the woodshed at the dacha, remember that you cannot place them directly on the ground.

To cover the floor of the structure, you can use construction pallets, which you can buy, or simply boards and other material that you have at your dacha.

The main thing is that the coating is continuous and completely covers the ground.

Video:

Varieties

There are different types of wood burners.

They differ from each other in several ways:

- installation location;

- material;

- form.

First of all, choose the installation location. It should be as close to the stove as possible.

There are three options:

street stationary location

mobile structure

placing a small firewood inside the bathhouse

The first option is used in estates where no changes in the location of outbuildings are expected, and the size of the bathhouse requires the use of large volumes of firewood.

The second option is used in estates with limited free space. They build firewood sheds on a movable platform (usually it is installed on wheels) and move it to a place where the structure does not interfere with anyone at the moment.

Installing a small storage unit inside the bathhouse allows you to avoid having to go outside once again to add another portion of fuel to the stove. As a rule, the volumes of such firewood boxes are small and require frequent replenishment.

The structure can be built from different materials:

wood (including boards, bars, logs and other types of lumber);

pallets;

metal (pipes, angles, fittings, other types of rolled metal);

piece building materials of the traditional type (brick, cinder blocks, etc.).

Most woodsheds are made of wooden parts. These can be boards, bars; they often use slabs and other types of inexpensive and practical materials. More durable brick or block structures are built to increase fire safety - in a non-combustible compartment, the spread of fire can be prevented in the event of a wood fire.

Metal firewood sheds are made to increase the speed of assembly, strength and durability of the structure. Firewood loggers made from rectangular aluminum pipes are famous for their particular practicality. Manufacturing requires a certain number of pipes and several hours of time, and the service life of such a structure is practically unlimited.

There are also decorative models, decorated with forging and other original details. As a rule, they are installed inside the bathhouse to create a certain style in the interior of the room.

Size and design

Dimensions are calculated strictly individually. They depend on the number of woodpiles that will be simultaneously stored in the building. Reserves must fully satisfy the need for this type of fuel at the site. For example, if only a fireplace is heated with wood, then a small, compact firewood rack, designed for two or three woodpiles 1-2 m wide, is sufficient. As for the design, the number of options is almost unlimited. Firewood boxes can have square, rectangular, round and semicircular shapes. Roofs are usually made with single slopes, but if the master decided to carefully work out the design of the building, to make it beautiful and unusual, then there are more complex options: gable, half-hipped, hipped, covered with tiles or ondulin. Of course, the process of building such a woodshed will take much longer. The buildings can be three-walled without doors or full-fledged barns that are completely closed.

Installation of a free-standing woodshed

The design of the product is similar. The difference is in two points - the canopy can be beveled in any direction, a foundation is required.

Please note that the diagram is similar to the previous one and can be used for a firewood shed adjacent to the house. Elements of longitudinal and transverse strapping have been added here

If desired, you can make the wall cladding continuous or sparse, including the front wall, and additionally hang the door.

The foundation in this scheme is shallow blocks or a shallow strip foundation.

The scheme with a gable canopy is also close to the previous one.

In this option, there is no sheathing as such - its role is played by crosspieces made of timber on the side walls of the woodshed. Instead of individual rafters, simple triangular trusses are used, and the role of the longitudinal strapping is performed by rafter beams at the top and timber flooring at the bottom

If trusses are used for a gable roof, they are assembled separately using a template and only then attached to the frame. Another difference between a design with a gable roof is that the ridge needs to be protected from leakage. For this purpose, additional elements are used, which can be purchased complete with roofing material.

Attaching the frame to the foundation

If the firewood shed is installed separately on a foundation made of concrete, brick or blocks, it is necessary to properly attach the wooden or metal frame to the foundation.

There are several options:

- mortgage with a U-shaped holder, used for monolithic bases. The mortgage is installed at the pouring stage, the frame is fastened after the base has reached its design strength;

- anchor bolts (dowels) on top of the waterproofing. To increase the service life of the support (crown) beam or board, lumber is impregnated with an antiseptic;

- studs to the foundation over the waterproofing.

The last two methods are applicable for both monolithic and block foundations. The first method is suitable for block bases to a limited extent, only when using a fastening profile with a supporting plane.

When using a foundation, there are two options for the installation sequence:

- first secure the racks to the foundation, then assemble the frame;

- fasten on the base of the post of the already assembled frame.

The first option is convenient for small point supports with already concreted embeds, since otherwise it is difficult to guarantee the correct placement of the posts. The second method is universal.

Types and advantages of wood burning for a bathhouse near it

The combination of the development and landscape of the land plot, the wealth of the owner, and the appearance of the bathhouse determines the type and location of the block for storing a supply of logs.

There are many options for the placement and design of firewood racks near the bathhouse: each steamer brings his own vision of the convenience of using the sauna to the standard design.

The following types of storage exist.

Attached to the wall

The attached woodshed is arranged in the same style as the bathhouse

Particular attention is paid to the roof

It is important that the drain does not leak into the adjacent storage area. Isolation of logs from the log wall should prevent the penetration of wood pests into the structures of the main structure

Fire danger is a significant disadvantage of this arrangement.

Isolation of logs from the log wall should prevent the penetration of wood pests into the structures of the main structure. Fire danger is a significant disadvantage of this arrangement.

Under the same roof

A firewood storage and a bathhouse under a single roof are arranged when logs are the main type of fuel for the steam room.

This option is a special case of constructing a complex structure for a utility block and sauna in accordance with the project developed before construction.

In order for the bathhouse with firewood to fit organically into the design of the buildings on the site, the combination must be planned at the stage of working out the placement of the object.

Carefully! Fire safety with this storage location is given special attention

Autonomous

The woodshed near the bathhouse is an autonomous woodshed. It is a covered space protected from rain and snow on all sides. The logs are isolated from contact with the ground by a gap of ≥10 cm. The walls should not be too dense - air circulation is carried out through them to dry the firewood in the woodpiles. A positive point: the ability to store brooms prepared for the winter for the steam room.

Portable

The portable firewood holder for a bathhouse has compact dimensions, which allows you to carry logs in your hands for 1–2 fireboxes.

Such storage belongs to the short-term category, for the period of warming up the steam room.

The supply of firewood and logs from the mobile basket is consumed quickly; it is not considered as a way to save from precipitation.

Serial with accessories

Serial firewood for logs and bath accessories is offered by many manufacturers at a relatively low price: from one and a half to 5 thousand rubles. This is not only a means for placing firewood, a poker and a scoop near the firebox, but also a thing with artistic features that can enliven the interior. Models of firewood racks made of forged metal are especially attractive.

Each of the listed types of wood burning for a bath has advantages and disadvantages. But under some circumstances, the disadvantages become advantages.

Do-it-yourself firewood for a wooden bath

A sauna heated by a traditional stove requires the preparation of a large number of logs. For storage and protection from adverse conditions, firewood sheds are erected for the bathhouse. Instructions for self-construction will allow you to take into account all the nuances.

Features of firewood sheds

Do-it-yourself firewood for a wooden bathhouse is built with lattice walls like blinds. In this case, precipitation during oblique winds will not get inside, and water will flow down the canopy. But even in a cobbled-together structure, with short intervals, the logs dry well.

It is necessary to ensure dryness inside the structure, so the top of the woodshed is closed and the floor is insulated from the ground. The structure is installed at a height of 20 cm. If this rule is not followed, this will lead to rapid rotting of the fuel.

During construction, it is necessary to consider ventilation. To do this, during storage you need to leave gaps between the firewood. The logs are prepared in advance and left to dry.

It is recommended to cook logs in winter, since when splitting you need to put in a minimum of effort.

Types of structures

You can build a loggerhead yourself, purchase a finished product in a store, or order a forged model from a workshop. But before making a purchase, you need to select an option based on the purpose:

- The portable model holds a small number of logs. Their compact size does not require effort to carry.

- Street structures are constructed as separate buildings or extensions. They are usually placed in the garden near the sauna.

- Extensions to the bathhouse are built near the wall and are made in the same style as the house.

Traditionally, the sauna is warmed up and heated using a stone or metal stove. Therefore, firewood is prepared in advance, and proper storage determines the quality of the kindling.

Types of woodburners

There are many options for placing a woodshed near a bathhouse. At the same time, the owner can make changes to the basic elements at his own discretion based on ease of use.

How to do it yourself?

Below are instructions for creating firewood loggers. Let's start with the option of a free-standing woodshed. To build such a structure, it is necessary to make manufacturing drawings so that the firewood shed turns out to be of a given size and fits into the landscape. The base will be 6 logs. These are the supports that create the frame. Let's look at how to build a firewood shed step by step.

Please pay attention to the following details

- Be sure to take into account the slope of the roof so that the snow falls down unhindered.

- The roof must be larger than the woodshed. The protrusion should be about 25 cm.

- It is necessary to have a floor that is raised 10 cm above the soil.

- There should be gaps in the walls and floors for free ventilation. These elements are made of wood.

- Treat all wooden materials with an antiseptic before fastening.

- You can decorate the woodshed with carvings, plants, and sculptures.

- To protect firewood from moisture, create drainage.

There are a number of distinctive features for such a building.

It is necessary to pay attention to the fact that the woodshed is located close to the house. It is necessary to ensure that water from the roof of the building does not fall on the firewood. The woodshed located in the north will insulate the northern wall of the house

The house will shield the firewood from unwanted light. In this case, a floor is also needed. Firewood should not be stored directly on the ground. To add aesthetics, you can make doors that will close the firewood. If you place the firewood shed on a covered terrace, then leaving the house for logs will be more pleasant and easier.

On the Internet you can find many ready-made projects with drawings and pictures for various firewood makers. The option you prefer depends on the availability of space, capacity requirements, availability of materials and imagination. The size of the firewood shed will be determined not only by the space available on the property, but also by how much wood is required to store the firewood.

Let's consider a few more options that will look original and allow you to use available materials. You can make a woodshed from barrels very quickly. Make rings out of barrels by knocking out the bottom. Place the barrels on top of each other and secure. Place firewood in barrels, but do not forget that firewood needs air, so do not fill the barrels too tightly.

Woodsheds are also made from an old rabbit house. If there are buildings left at your dacha that are no longer used for their intended purpose, then make a place out of them for firewood:

- disconnect the doors;

- repair the roof so that it is strong and protects the firewood from precipitation;

- repair the frame or replace it with mesh.

You can also make a woodshed from pallets. This option is very easy. The boards in the pallets are already nailed together at a distance. All that remains is to assemble the structure from the pallets. From 5 pallets you can make a cube, which can be placed on a base or covered with a roof. You can make a large shed out of cubes. You can also make a woodshed from concrete rings. To do this, you just need to lay the ring or several rings horizontally and secure it. This is the simplest idea for a woodcutter.

Spend a little time and effort to create a firewood shed that is convenient for you and protect your firewood supplies from bad weather and dampness. Proper storage will not only preserve firewood, but also make it more suitable for use. A firewood shed can not only become a convenient and necessary building on your site, but also become a decoration element. Drovniks are decorated with carved elements, plants, and bindweed. You can place a bench next to the woodshed. It is advisable to make the woodshed in the same style as other buildings. It all depends on your desire and imagination.

To learn how to make a woodshed for your dacha with your own hands, watch the video below.

Do-it-yourself firewood for a bath - made of wood or metal

The traditional fuel for a real Russian bath has always been firewood, which needs to be stored somewhere and protected from external influences. A good owner always has them in order and at hand. For these purposes, special designs have been used for a long time: woodshed, woodshed or woodshed.

What is a woodcutter

The woodshed is a separate, free-standing building, often with its own foundation. Such a structure may look different. However, it is always built according to the general principle - it is located without adjoining a residential building, and consists of enclosing structures and a canopy. Its dimensions are determined based on the amount of firewood that will have to be stored. Most often, wood is chosen as the material for building a woodshed. This solution is practical and fits perfectly into the landscape of country houses. A high-quality woodshed should have good ventilation and reliably protect the logs from precipitation.

Additional information: when building a woodshed, it is important to exclude the possibility of direct contact with open ground.

Product Features

When planning to organize a place to store firewood on your site, you should first decide on the type of structure:

- The woodshed is an autonomous, separate building with its own foundation;

- Drovnik is a type of woodcutter, but in a simpler design. Often it looks like a shed adjacent to the main building. The foundation for such a structure may well be the blind area of a house;

- A firewood rack is a mobile structure like a basket for moving logs and a stand for loading them into a fireplace or stove.

An important step before starting construction is to decide on the location. The woodshed should not be too far from the house. The place should ideally be in the shade so that in hot weather the aggressive rays of the sun do not damage the firewood. The utility unit should be discreet and echo the overall design concept. It is necessary to provide a special stand for firewood in advance to avoid unwanted contact with wet soil. To take into account all the details, the firewood for the bathhouse should be included in the drawings at the stage of planning the entire site.

What are they built from?

Woodsheds are made from a wide range of materials: from brick and wood, to metal and stone. The choice of suitable material will directly depend on the purpose of use of the structure and its location. Most often, the frame of the woodshed at the bathhouse is made of wood or metal. In the first case, it will be necessary to impregnate with antiseptic solutions.

Metal firewood rack for a summer residence

Metal is one of the strongest and most durable materials. That is why firewood logs for bathhouses are often made from it. A metal firewood rack will be an excellent mobile solution for a small amount of firewood. These firewood racks have an attractive appearance and are made of aluminum profiles.

A more solid option is a stationary design. The frame is made of a profile pipe or channel and sheathed with welded mesh or other material.

Attention: metal surfaces must be coated with anti-corrosion compounds or special primer enamels.

Wooden firewood for a summer residence

The woodshed can be constructed of wood. This option is most common due to its simplicity. Available materials are used. Any wooden blanks will be useful: boards, beams, even old pallets. Then it's up to your imagination. You can make an option with the simplest outlines, or you can think of an unusual wall decor by adding carved elements. The only condition is that the structure must be well ventilated so that the firewood has time to dry.

Types of woodsheds

The structure called a firewood shed has one task - maintaining order and organizing conditions for proper storage of logs. But there are a lot of possibilities for locating the woodshed near the bathhouse. The choice of one option or another is determined only by taste preferences and an acceptable financial component for the owner of a bathhouse or sauna.

Woodshed adjacent to the building

This option is considered the fastest construction. There is no need to build a back wall - the wall of a house, bathhouse, or any other building can act as it. The appearance of the side walls and roof can be anything. Often a polycarbonate canopy is used as a roof; this is a budget and practical solution. In addition to the roof, there must be a floor. There may not be any side walls. If the woodshed is in plain sight, you can think of a more aesthetic option, consisting of several sections of different shapes. It is advisable to place the structure on the windy side so that the firewood is well ventilated.

Important! Small pests like to live between densely stacked logs. To prevent them from migrating into the house, you need to isolate the structure from the wall of the building. A sheet cut from metal is suitable for this. The wooden structure must be treated with compounds from a group of insecticides.

Free-standing woodshed

This option refers to more substantial buildings and may well become an element of the landscape design of the site. A free-standing firewood shed must have a construction plan. The design can be open type with lattice walls. A popular option is to build a woodshed based on the gazebo principle. In this case, pillars are dug in that will serve as support for the roof. The base is placed at a distance of approximately 0.2 m from the ground. The walls can be anything, the main thing is to ensure air exchange.

Creative and original ideas for placing firewood in the form of columns

If you want to not only place firewood for the fireplace in a niche in the wall, but want to do it in an original and unusual way, then turn the woodshed into a column! Rectangular niches in the wall can be filled with firewood up to the ceiling or hidden in the corner of the room, it all depends on your taste preferences and the overall style of the room.

So, in the photo below there is a small living room from the designers of Capoferro Design Build Group, who placed a small rectangular woodshed in the corner of the room. Now the niche in the wall is only half filled with firewood, but if desired, the firewood can be stacked up to the ceiling of the room.

Rectangular woodshed in the corner of the living room.

The designers of Designdock Lakberendezés built a real column of firewood for kindling next to the built-in fireplace. The unusual firewood rack has become an excellent decoration for a cozy reading corner.

Woodshed-column in a wall niche.

To create the right balance and harmony in the room, follow the basic rules of symmetry when decorating the interior. So, the designers of the D'apostrophe Design company placed two small column firewood burners in niches on both sides of a small built-in fireplace.

Symmetrical wood burners in niches near the fireplace.

A small rectangular woodshed in a wall niche.

Stylish woodshed in a white living room.

The photo below shows a simple and stylish option for storing firewood from the designers of InHouse Design Studio, who placed a small firewood rack in a cabinet niche.

A small woodshed in the niche of the closet.

Woodshed-column in a stone wall.

Drovnitsa

There are many options for a firewood rack as a storage facility for the consumable batch of fuel for a fireplace (on the left in the figure), but it is not functional. To carry firewood, you still need a separate firewood basket, and when you transfer it to the firewood stand, debris spills onto the floor.

Metal firewood racks

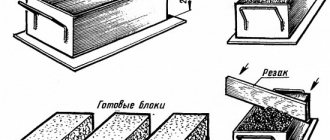

There are also a lot of combined firewood racks (other items in the figure) of varying capacity, complexity, convenience and cost. But in this series, a firewood box made from an old barrel or small barrel deserves special attention, see fig.:

Diagram of a firewood maker made from a keg or small barrel

- Original, stylish, fits perfectly into most interiors with a stove or fireplace.

- Made from a barrel, it holds a load of firewood for the daily heating of the stove.

- A firewood box made from a barrel/barrel can be dragged through the snow like a sled by attaching a strap to it, but an armful/bundle of firewood weighs a lot.

If you find a suitable blank for a firewood box from a barrel/barrel, then keep in mind that you cannot knock out both bottoms at once or the remaining one will crumble. You must first fasten the hoops with rivets with self-tapping screws, having first drilled holes in the hoops for them. You need to drill with a drill with a drill depth limiter, but a construction drill is not suitable, its probe is too far to the side. The drill tucked into the tool must be tightly wrapped in thin sheet metal (for example, from a coffee can), so that its tip protrudes from the wrapper to the thickness of the hoop, and the wrapper must be wrapped with thin wire. You need to screw the tin stop onto the drill AGAINST the direction of its rotation so that it does not turn around when the wrapper rests against the metal of the hoop.

Video: examples of making simple firewood racks - for carrying firewood and for barbecuing

***

2012-2020 Question-Remont.ru

Display all materials with the tag:

Go to section:

Peculiarities

Decorative firewood - can be indoors or outdoors. Be an additional functional and decorative element in the interior or be an element of landscape design.

firewood holder - installed indoors or in open and closed gazebos with a fireplace. They are made portable or stationary, organically fitting into the overall interior. They are made from wood, metal, thick fabric and other materials.

Types of woodsheds

You cannot throw logs randomly into a woodpile. They should be folded correctly for better preservation.

Methods for stacking firewood:

- Circular method

- "Stack"

- With stakes

Circular method

If you do not have a stationary woodshed, then you can stack the logs in the form of a barrel tower. It is necessary to drive a stake. It will serve as the basis of the structure being built.

Tie a fishing line or rope and draw a circle of a given diameter, depending on the amount of raw material. To prevent them from becoming damp and rotting, place tree bark or thick plastic film on the ground as a base.

Place the firewood on it in a circle carefully and tightly so that the structure is stable and does not sag. By laying firewood about 0.5 m high, you can fill the middle by stacking them in any order, but quite tightly. Continue laying in this way until the barrel tower is about 1.5 m high.

"Stack"

Stacking of logs is often used. This type of installation requires support. The wall of a house, bathhouse or other building is suitable as a support; firewood grate for a summer residence. When laying, strictly control the slope towards the support. If you are laying two rows, then place thinner logs on the support and thicker ones on the outside. Due to the difference in size, there will be a slope towards the support.

If your structure stands separately from the wall, then use a wooden beam as a support. The height should be small, otherwise, under the pressure of the firewood, the support beams may break and the structure will fall apart.

With stakes

If it is not possible to lay it otherwise, you can use stakes as a support. The stakes must be those that will not bend from the logs. Drive them into the ground from several sides, forming a frame.

When stacking firewood, line each row with branches. They will play a reinforcing role. Place the logs in a checkerboard pattern. The top must be covered with any covering material that does not allow water to pass through.

We build a woodshed with our own hands

In this section we will describe how the woodshed was built near the house. The construction and painting took three days “without stress.” It was built like a frame barn.

Materials

Internal dimensions are 1.8 * 3.7 m, the height of the front pillars is 2.45 m, the rear pillars are 2.2 m. The total volume is 13 cubic meters, but a maximum of two cars are loaded - no more than 10 cubic meters. Moreover, they leave paths inside - to make it easier to take, they don’t load it to the top - not everyone in the family is tall. If the load is full, it is advisable to install additional jibs so that the weight of the firewood does not squeeze out the sheathing boards.

The frame is made of timber - racks, the lower and upper trim are made of 100*100 mm timber. The timber is pre-impregnated with used machine oil. Everything was assembled end-to-end, with nails, and reinforced with corners on screws. For the supports, standard small foundation blocks 200*200*600 mm were purchased in the amount of 6 pieces.

Construction step by step

The beginning of the construction of the firewood shed is standard - leveling the site and aligning the blocks. If the soils are viscous (clay loams, black soil), it is better to make a sand and gravel bed. Dig small pits 20-25 cm deep, pour and compact crushed stone, and place blocks on top.

Leveling the site is the first step in building a woodshed

Two layers of roofing material are laid on the blocks, timber is laid on top. The harness does not connect with the support in any way. If you wish, you can drill holes and hammer in the studs.

First, we laid out the beams of the lower frame and fastened them with nails (80*3 mm). Then screws were screwed into the corners. The next step is installing the racks. They are placed in the corners and above the intermediate support. The rear pillars are shorter than the front ones - so that there is a roof slope. They, too, were first placed vertically (checked with a plumb line), and hammered in obliquely with nails - two on each side. Then they secured them with corners on screws - two per rack. If there are concerns, you can also screw/nail the plates to each rack from the outside.

The racks are attached to the bottom frame beam

The entrance to the woodshed is located in the center. Because of this, the racks are offset and not installed above the support block. As a result, there is a slight deflection. To eliminate it, place four blocks in the first row, taking into account that the middle will be occupied by the entrance. Especially if there are doors: they place a significant load on the racks, so they need support.

In front, the intermediate posts are not above the support

Once the posts are in place, it's time to assemble the roof. First I nailed the side boards at the top. They are installed on the same level with the upper trim of the rear, shorter part (seen in the photo below). They and the rafters are made of 50*100 mm boards, the lathing is made of 30*100 mm boards.

Corrugated sheets were used as roofing material, and the boards were laid flat under it. The roof overhangs are about 35 cm, the side projections are about the same. The size of the roof was selected so that there were no scraps: exactly four sheets were used.

Roofing felt is laid under the corrugated sheet to prevent condensation from dripping onto the firewood: the costs are small, but there are benefits. Ruberoid began to be laid from below, laid along the overhang. The next one goes in 10 cm. It turns out that the drop that fell at the top simply flows down without getting inside.

This is what a woodshed with a finished roof looks like

The next step is to lay the floor. It was made from a 100*40 mm board. They were laid with gaps of 2-3 cm. Next, the wall sheathing was nailed. It was decided to make a gap equal to the width of the board (100 mm). The boards were nailed down, two on each edge. The structure turned out to be well ventilated, however, with a side wind it gets heavily clogged with snow.

Do-it-yourself woodcutter is almost ready

The last stage is painting. Here, take any composition for wood with bio-protective properties: so that the bugs eat less. In this version it is painted with BioTex, rosewood color.

Ready for use after painting

That's it, the woodshed is built. You can repeat this: nothing complicated. The complexity of carpentry work is at the level of high school students. The most complex components are the roof, but it is made very simply.

See the video for another construction option.

Questions and answers

Let's look at the most common questions that arise during the construction of a firewood shed:

Do you need a foundation for a brick firewood shed?

The weight of the structure is small, therefore, most often they do without building a permanent foundation. However, if the soil is too pliable and loose, it is necessary to create a reliable support structure. The recommended option is a pair of screw piles with a top frame and a platform.

Do I need to treat the parts of a wooden structure with an antiseptic and fire retardant?

Yes, this procedure is strongly recommended either before or after assembly. Logs can be infested with insects, which can quickly destroy a wooden firewood logger. Therefore, the application of protective impregnation in this case becomes a mandatory stage of construction.

Which option for assembling a metal firewood box is better, welding or threaded connections?

There is an opinion that it is more profitable to assemble it using bolts and nuts - if necessary, the woodshed can be disassembled completely or partially, expanded or reconstructed. However, this method may be unnecessarily expensive and will not give the expected effect. Bolts quickly rust, even when a protective layer is applied. Disassembling such a structure becomes too difficult, and it is simply cut with a grinder. Therefore, it is easier and faster to assemble a metal firewood log with welded joints.

Is it possible to combine a woodshed with a carport?

This is an undesirable combination option, since the firewood can absorb the odors of fuel or oil. If you still combine the firewood shed with a shed, then install a wall between the two compartments so that the logs do not absorb odors. In addition, fire safety must be taken into account.

How far from the entrance to the bathhouse should the woodshed be located?

This is a matter of ease of carrying logs, which is done manually. The closer the woodcutter, the better. If it is too far away, you will have to make some supply of fuel inside the bathhouse, which is not always convenient.

Manufacturing technology for a mobile woodpile for a bathhouse

Metal portable firewood for the bathhouse

- We weld four identical twigs into a square.

- We bend two rods in the shape of the letter Y. The distance between the “legs” should be equal to the length of the sides.

- We weld the sidewalls to the resulting frame. As a result, the arcs will rise up, and the tips will protrude beyond the base, forming a kind of support.

- We weld metal plates to the legs. This will give the structure stability.

- We weld a few more rods at the base and walls. This will prevent the firewood from falling out.

To make the structure last longer, it is advisable to paint it.

Do-it-yourself wicker woodpile for a bathhouse

- We knock together a square base from four wooden slats.

- Every three centimeters we drill holes on two opposite slats.

- We insert willow twigs into the holes made. In the middle, instead of rods, we insert a wire, the ends of which are bent with pliers.

- We bend the racks at the desired angle and intertwine them with thin rods.

- At the end of the weaving, we bend all the posts, bring them behind the adjacent ones and weave them from the inside.

- We wrap the handles with several rods and cover the ends.

It is advisable to soak the vine in water before use. This way it will be more pliable. In addition, it is recommended to pre-treat it with an antiseptic composition to increase service life.

How to make a wooden firewood rack for a bathhouse

- We cut out two trapezoidal elements with a height of 20 cm from the board. The width of one side is 25 cm, the second is 30 cm.

- At a distance of 5 cm from the edge of the wide side, cut a hole in the middle 9 cm wide and 3 cm high.

- We round and sand the walls of the hole with fine-grained paper.

- We connect the lower parts of the two parts together with slats 45 cm long, which we nail close to each other. We use nails as fasteners.

- We nail two slats on each side, forming peculiar walls. Leave a gap of 1-1.5 cm between them.

- We round the backs above the arms. This can be done before assembling the entire structure.

- We carefully sand all surfaces, first with coarse and then with fine-grained paper. This is necessary to protect against splinters during operation.

In order for such a woodpile to last longer, it is advisable to treat it with an antiseptic composition.

Firewood tins

Recently, various household containers are often used in country decor. For example, here are these vintage brass or copper troughs from the 40s:

Copper trough for firewood. Photo from placesinthehome.com

Or charming buckets:

Original firewood owl. Photo from flowhearth.com

Trough for firewood. Photo from jossandmain.com

They look good on their own. And although not everyone likes their brutal simplicity, it provides incredible scope for creative experiments. What interesting things can you do with a bucket or trough?

- Decorate with hand painting;

- practice decoupage techniques;

- age the surface in shabby chic style;

- just paint it.

Firewood-clothes

If you wish and have the skill, a firewood stand can be felted from wool or sewn from an old coat

Oh, what is this? Firewood in your coat! Photo from uncommongoods.com

...or from any other suitable material:

Canvas firewood stand. Photo from bestmadeco.com

True, such a firewood rack is more suitable for the role of carrying: keeping it near the fire, in my opinion, is risky.

Wooden stands for firewood

There is a whole forest of possibilities here. You can take a regular box:

You can take a regular wooden box

And to make it not so boring, decorate it and screw on the wheels.

Use a gang for a bath, create a composition from slats, or saw a barrel:

Wooden half-barrel firewood box. Photo from etsy.com

At worst, wait until the New Year and borrow a sleigh from Santa Claus:

Firewood sled. Photo from potterybarn.com

And the most unexpected option is to put together a stand for firewood from the firewood itself:

Firewood rack. Photo from onekingslane.com

Wooden coasters, just like wicker, wool and fabric ones, have one significant drawback: they can easily catch fire. So whatever option you choose, safety comes first. Be careful!

Where do you store the “on-duty” supply for kindling?

303

Types of wood burners

Firewood can be indoor or outdoor. The first ones are located directly in the room. They usually don't take up much space and store a limited supply of fuel for the fireplace. Street ones are much larger in size. They are used to store large amounts of fuel necessary for servicing a fireplace, sauna, or barbecue. Depending on the location, outdoor firewood sheds are classified into two types:

- Attached to a house or other outbuildings.

- Freestanding. As a rule, they are placed away from the house, but not far from the bathhouse or recreation area in the area where barbecue is usually grilled.

Depending on the type of structure, they can be stationary or portable. The second ones are used for storing small woodpiles. Open firewood sheds are a covered structure on supports (sheds). Closed ones are complemented by walls and are more reminiscent of typical households. the buildings.

Advantages of forged products

A forged metal stand for firewood in a bathhouse is designed for long-term service, and therefore requires especially serious treatment. Compared to other types, it has a number of undeniable advantages:

- has higher resistance to changes in temperature and humidity, which is very important for a bathhouse due to the constant presence of water and steam;

- Possibility of use both outdoors and indoors;

- reliability under heavy load.

With the right choice, a forged woodpile will delight the owner with durability and strength, an elegant appearance, openwork intricate patterns will emphasize the aesthetic taste of the owner.

The firewood stand should complement the overall picture of the room and harmoniously match the rest of the accessories and the style of the interior.

Construction of a stationary firewood rack for a bathhouse

Construction of a foundation for a stationary firewood shed for a bathhouse

- We drive four pegs in the corners and two in the middle of opposite sides.

- We check with laces the evenness and identity of the diagonals.

- We dig holes to the depth of soil freezing.

- We install square formwork made of slats around each recess.

- Using a level, we level the plane in which the formwork is placed. This is necessary so that all foundation pillars are at the same height.

- We lower a sheet of roofing material into each hole to protect the solution from moisture.

- We make a solution of cement, sand and crushed stone in a ratio of 1:4:4 and pour it into each hole.

- We insert reinforcement with a 12 mm thread into each hole filled with concrete. The pin should protrude 9 cm above the concrete column.

Before proceeding with further work, you need to wait until the base is completely dry, after which the side walls can be covered with ceramic tiles to protect the base from moisture.

Installation of a frame for an outdoor woodpile near the bathhouse

- We cut the timber with a section of 10*10 cm along the length of the walls. There should be five of them in total: four around the perimeter and one in the middle.

- We drill holes along the edges of each element using a 13mm long feather drill.

- We put longitudinal bars on the studs, install transverse ones above them and mark the intersection points for the cutout.

- We tie half the tree. We file the cuts along the edges and chop off the excess using a chisel.

- We lay a layer of roofing material, longitudinal elements and then transverse ones, having previously treated them with machine oil or rubber-bitumen mastic.

- We screw the nuts onto the studs, enlarging the hole at the top using a router. This is necessary to secure each bar.

- We reinforce the floor with joists and screw 2 cm thick slats with self-tapping screws.

- We nail boards along the side perimeter to cover the strapping bars.

- We cut the timber with a section of 5*5 cm. The length of the segments should correspond to the height of the front and rear pillars.

- We prepare two 15-centimeter boards with a thickness of 3 cm. Their length will be equal to the width of the structure.

- We sand all the parts using an electric planer.

- We cut notches on both boards, one for each support.

- We fasten the racks to the boards with self-tapping screws and to the floor using mounting angles.

- We strengthen the supports with spacers and check the evenness and parallelism with a hydraulic level.

- We stuff two-centimeter slats in a horizontal position with a gap of 2 cm, forming peculiar walls. The gaps between the slats are necessary for ventilation.

It is important to paint or coat all wood with antiseptic compounds so that the building lasts longer.

Construction of a roof for a firewood shed near a bathhouse on the street

- We install 10-centimeter boards with a thickness of 3 cm over the building with an overlap on both sides; they will serve as rafters. We use metal corners as fasteners.

- We screw 2 cm thick slats to the boards in 0.5 meter increments. This is a lathing for installing roofing material.

- We fasten the metal profile sheet with construction screws.

- We fix a wind strip at the ends of the roof to protect the structure from slanting rains.

The door does not need to be installed. You can use bamboo blinds as a kind of damper.

Construction stages

1 You have a question: “How to build a woodshed from wood at the dacha with your own hands?” We need to know the amount of firewood that we will place in it. If you only need firewood to barbecue or light a fireplace in cool weather for the season, then you will need a small firewood shed of 1.5-2m3.

This can be a free-standing structure or randomly folded blocks. If they are needed for a bathhouse, for frying barbecue, and for heating the house, then it is worth building a woodpile with your own hands, taking into account the consumption of firewood for 2-2 years. It takes from 2.5 to 6 cubic meters of firewood per year to heat a house. Only after a year does the firewood dry out well enough and produce good heat when burning.

Wet firewood (recently prepared) burns poorly, produces a lot of smoke and produces almost no heat.

2 Choosing a place on the site for firewood

Take seriously the issue of choosing a place for a woodshed. Consider whether you are ready to build it stationary or a portable option will do.

If you plan to heat a house or bathhouse, then it would be reasonable to locate it near them or make an adjacent canopy. The approach to the woodpile should be convenient; it is advisable to lay paths to it. The place itself should be dry and shaded. It is better to pave the base of the woodpile, pour a concrete blind area, or, alternatively, use wooden pallets so that the firewood does not have contact with the ground.

3 Let’s start building a wood firewood shed with our own hands

The simplest option:

1 Take two three-meter boards 250mm wide for the base

2 Cut a two-meter board into 25 cm pieces, take 4 pieces for the base

3 For vertical racks, cut 4 boards of 1.5 m each

4 We twist the boards for vertical posts and short boards together, then screw three-meter boards to them

5 We fix the remaining 25 cm of boards in vertical boards in the middle and on top.

6 It is advisable to treat the structure with an antiseptic or paint it so that it does not deteriorate under the influence of precipitation.

7 Making a canopy

If you have a free-standing woodpile and it is not possible to make a stationary canopy, use any covering material (roofing felt, polycarbonate, slate sheet, etc.)

For a woodshed built with your own hands, you can make a pitched roof.

The main function of a canopy is protection. It protects against natural phenomena and also provides ventilation for wooden chocks. It is necessary so that the logs dry out and are not exposed to putrefactive fungi.

Cover the canopy with sheets of metal profiles, colored or galvanized, slate, polycarbonate, brick, etc.

Video description:

Outdoor firewood rack for a summer residence

If the size of the barn allows, wooden logs are placed inside. The advantages of such placement are as follows:

firewood is not exposed to atmospheric conditions;

aesthetic, they are not scattered on the site;

there is no need to build additional outbuildings;

firewood can be stored for a long time without changing its characteristics;

they are hidden from prying eyes and unscrupulous neighbors.

DIY firewood shed

If the size of the barn does not allow you to place wooden logs inside, make an extension to the barn from the outside.

Advantages:

-saving space and materials;

-convenience, all buildings are nearby, no need to go far;

- additional thermal insulation of the adjacent room.

1 Install the extension on a flat surface. It’s good if the blind area is already made of concrete, brick, tiles or asphalt.

2 Make a base from bricks, concrete blocks or wooden pallets. The base is necessary for ventilating the firewood.

3 The frame can be made of metal pipes or wooden blocks. Metal pipes can be used round, profile or channel. If you plan to use the woodpile for a long time, assemble a solid structure by digging the woodpile posts into the ground to a depth of 0.5 m

4 If you use metal pipes as racks, then make the walls of the woodpile from welded mesh by screwing or welding it.

5 If you use wooden beams as racks, then the walls can be covered on one, two or three sides, depending on the design of the building. Suitable materials include slats, boards and other materials.

The main thing to remember is that the structure must be ventilated.

There is one drawback. Insects and wood pests come with the delivered firewood. Therefore, it is worth protecting the wall of the shed adjacent to the woodpile. It can be treated with special protective agents or a sheet of metal nailed to the wall.

DIY woodshed

As mentioned above, the woodpile can be stationary or portable.

They can be both inside the house and outside.

Stationary outdoor firewood sheds are often built separately. They can be in the form of a closed firewood shed or in the form of a very simple canopy. Such a woodshed can be placed far from the house and other outbuildings for fire safety purposes.

When building it, you need to fill the foundation in compliance with all the rules. Dig a ditch around the perimeter of the woodshed under construction to a depth of soil freezing of up to 1 m. We fill in layers of sand and crushed stone and compact each layer thoroughly. We pour the concrete foundation.

You don't have to fill the foundation. To do this, remove the top layer of soil, cover it with sand and compact it well. Place a base of stone tiles on the sand, on which wooden beams should be laid.

Next we install the frame. We sew up the walls. Walls can be made of logs, boards, wooden planks, metal pickets, polycarbonate. The main condition is that the firewood shed must be well ventilated.

We cover the roof with any available building material.

Drawing of a woodcutter with dimensions