The absence of a foundation under the stove will affect its reliability and safety.

Installation of piles for a heating device is the most economical and practical technology among existing types of foundations.

You can learn about the features of the method of making a pile foundation for a furnace, the cost of construction with your own hands and on a turnkey basis from the article.

Purpose of the foundation for the furnace

If the stove weighs no more than 250 kg, you can do without arranging a base. But if the floor in the house is made of wood, there is an extremely high probability of fire, so you should think about filling the base.

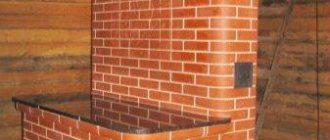

A brick kiln cannot be installed without a foundation; this is due to soil heaving and subsidence of the structure. If the foundation of the house is made using reinforced concrete, then the base for the stove may be of a different type. The foundation for the furnace will ensure uniform distribution of the load from the product and protect it from damage, destruction, and cracking.

Construction of a furnace on a foundation Source firreplace.ru

In general, the base will help to significantly extend the life of the fireplace, prevent a possible fire in the building and expand the functionality of the structure.

Nuances of laying the foundation

When arranging the base for a fireplace, you will need to take into account a number of certain rules. These include:

- The foundation for the stove in the house must be separate, not connected in any way to the base of the building itself. This is due to the fact that over time the house may sag. However, it should not be connected to the stove, otherwise this may lead to its deformation, poor draft or other damage. Sometimes it is possible to partially connect the bases with one wall.

- If the bases of the building and the fireplace are located nearby, they must be separated by sand-based backfill with a thickness of 50 mm.

- If the base of the building is strip, the base of the furnace should not come into contact with it in any way.

- When choosing the location of the heating structure and its base, you need to take into account the location of doors, windows and roof beams. It is necessary that the chimney pipe does not touch the ceiling beam during the installation process.

- When calculating the size and depth of the base, you need to take into account the weight of the stove with chimney and ceilings.

Loamy soil in section Source stroidominvest.ru

The size of the base depends not only on the weight of the stove, but also on the quality of the soil on which it will be installed. Most of the pressure is exerted by the chimney, so during the design process you should try to place it in the center of the base. This will prevent load asymmetry and shrinkage of the structure. The choice of base is also influenced by the material from which the stove will be built. The depth of the foundation for metal and brick fireplaces will differ significantly.

Comparison of support parameters

Screw piles have insufficient load-bearing capacity to withstand heavy loads of heavy structures, so in most cases they are used for the construction of lightweight and low-rise structures. At the same time, metal supports are economical and relatively simple to install.

A detailed comparison of pile and driven supports is shown in the table:

| Options | Screw supports | Driven rods |

| Scope of application | private housing construction, construction of low-rise residential buildings, agricultural buildings, garages, warehouses, fences and other lightweight structures, strengthening of existing foundations and slopes | civil and industrial construction, construction of transport structures, as well as engineering and hydraulic structures |

| Soil types | various soils, except rocks, as well as difficult areas prone to landslides and subsidence | |

| Difficulty of terrain | landscape with any elevation changes | |

| Maximum service life | 70–100 years | 100–150 years |

| Load-bearing capacity of one product | up to 7 tons | up to 10 tons |

| Susceptibility to corrosive processes | highly susceptible | not susceptible |

| Waterproofing method | cold or hot galvanizing, polyurethane coating, alkyd paint or primer application | adding hydrophobic compounds to concrete |

| Burying method | screwing method | using impact force |

| Impact of installation method on the ground base | the blades break up the soil masses, the soil takes time to shrink | reinforced concrete support pushes the soil, compacting it underneath |

| Installation speed | high, from one day | |

| Installation equipment | electric screwing machines, devices for manual installation (rods) | piling units |

| Possibility of DIY construction | installation requires the collaboration of at least three builders | impossible |

Average price:

| Construction type | Wooden house | Foam block building | Brick building |

| Screw piles | 120 thousand rubles. | 460 thousand rubles. | Not recommended |

| Driven piles | 200 thousand rubles. | 475 thousand rubles. | 525 thousand rubles. |

A lot of useful information about pile-driven foundations is presented in this section of the site.

Types of bases for the oven

The most common base options for such structures are:

- Based on continuous poured concrete.

- Rubble concrete.

- Support-pile.

A conventional foundation is built from rubble on a cement composition or from concrete. In size it should be approximately 100 mm larger than the area of the stove itself. The height used is the same as when arranging the base for a conventional building. Roofing felt or several layers of waterproofing are installed on the finished structure, a brick is placed on top, and with the help of metal corners it will be possible to guarantee fire safety.

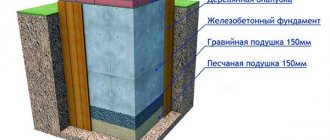

Scheme of the foundation for the furnace Source stopdacha.ru

See also: Catalog of companies that specialize in foundation repair and design.

When choosing the type of foundation and its size, it is necessary to take into account the quality of the soil. The density of the soil and the level of its freezing are of great importance. There are 3 types of soil: clay, sandy loam and loam. In areas where there are rivers, reservoirs and lakes, most often there is a sedimentary type of soil. In this case, it is better to entrust the creation of the foundation to specialists, since it will be necessary to perform accurate calculations of the water passage point.

A fairly common type of soil is loam, which contains sand and clay. Because of this, the soil has low plasticity rates, and the arrangement of the foundation can be problematic. The fact is that when dry, loam crumbles, in cold weather it swells, and when precipitation occurs, the viscosity increases significantly. To avoid complications with this type of soil, the depth of the base should be above the freezing point.

Advantages and disadvantages

Positive sides:

- Simplicity of installation of main communications, removal of sewer drains.

- Possibility of arrangement on different types of soil.

- Lack of sensitivity to soil heaving.

- Service life is about 150 years.

- Increasing soil density.

- Possibility to carry out foundation installation throughout the year.

- Repair of individual parts without dismantling the entire base.

- High-quality ventilation.

- Quick installation.

- Low price.

- Minimal shrinkage.

Flaws:

- To make metal piles resistant to rust, you need to buy products with an anti-corrosion coating.

- Standard piles are not suitable for laying foundations on rocky soil. For this purpose, specialized building elements are used, which are installed using special equipment. This increases the cost of the foundation.

- For buildings with a pile foundation it is impossible to make a basement. To do this, a number of additional works need to be carried out.

Arrangement of a concrete base

The foundation for a concrete-based Russian stove is created using the following materials and elements:

- Cement. If the soil contains a large amount of sulfates, sulfate-resistant cement of the SSPTs brand is best suited.

- Sand. You need a coarse-grained type without inclusions; mountain sand is the best choice; river and sea sand are also suitable.

- Formwork.

- Crushed stone.

- Waterproofing layer. Ruberoid would be a good choice.

- Container for preparing construction mixture.

- Bayonet and shovel shovels.

- Level for measurements.

- Hammer, nails and construction stapler.

Concrete foundation for a furnace Source hozsektor.ru

To build a high-quality foundation, you must carefully follow all instructions. The procedure consists of the following steps:

- Marking, digging a pit and filling it with sand and gravel.

- Arrangement of formwork and installation of reinforcement.

- Pouring concrete solution.

Digging holes and backfilling

The first step is to decide on the location of the stove, based on its size, the volume of the house, the number of windows and doors. The approximate dimensions of the structure are indicated on the ground. The base should be approximately 20 cm larger than the heating device. Pegs are used to mark the boundaries of the pit.

After which a trench is dug. It should be deeper than the soil freezing level and 100 mm wider than the base. Thanks to this backlog, it will be possible to avoid the consequences of possible soil movement. For dry sandy soils, the pit depth should be about 80 cm, for heaving types - at least 1 m.

Then a pillow is placed at the bottom of the hole. First, a layer of sand about 15 cm thick is poured and filled with water. When the water evaporates, add a small amount of sand and add water again. After which crushed stone and small stones are laid, the thickness of this layer should be 20 cm. The pillow is compacted, then sand is poured back in and water is poured in. The action must be repeated until the sand stops settling.

Installation of formwork and reinforcement

Formwork is installed along the perimeter of the trench. To do this, you can use old boards or sheets of plywood; the material will not affect the functionality of the structure in any way. Supports must be installed at intervals of 50 cm. It must be taken into account that there must be a free space of at least 10 cm between the formwork and the soil. At the corners, the structure is fastened with metal staples. The boards are fastened using nails.

The finished formwork is immersed in the bottom of the trench. Then you will need to waterproof the base. For this, polyethylene is used; it must be stapled around the perimeter to the formwork. Next is reinforcement. This will ensure the rigidity of the entire structure. Reinforcement is performed using steel rods with a cross-section of 12 mm, which are fastened together by welding or wire. At the end you will need to connect the floor to the foundation. To do this, you need to lay out an even row of bricks.

Concrete foundation diagram Source karelia-dom.ru

Arrangement of a rubble concrete base for the stove

Creating this type of base for a stove consists of the following steps:

- The trench is being marked. Just as in the case of a concrete foundation, the size of the pit should be 10 cm larger than the foundation itself so that the movement of the soil does not cause significant damage to the structure. A hole is dug out.

- At the bottom of the pit, a cushion is placed based on crushed stone with a thickness of 15 cm. The layer is carefully compacted.

- Then a layer of large stones is placed on the bottom, but they should not be more than 15 cm in diameter. Crushed stone is poured on top, which will fill the empty spaces between the stones.

- A cement-sand composition made in a ratio of 1 to 3 is poured. It is best to use cement grade 400 or higher.

- A day later, a new layer of stones is laid, and so on until the entire trench is filled. The layers of stones must settle, otherwise the service life of the rubble base will be significantly reduced.

- When the hole is filled, the evenness of the surface is measured using a building level. If irregularities are noticed, they are eliminated using a cement-sand composition.

- The smooth base is covered with film and left until completely dry. This takes at least 2 weeks. The solution must be constantly moistened and protected from exposure to the sun.

- After drying, the formwork is dismantled and waterproofing is carried out. You can use molten tar for this. The empty spaces between the base and the soil are filled with coarse sand and crushed stone.

Rubble concrete foundation for the furnace Source stroimdom.com.ua

It's better to be fully prepared

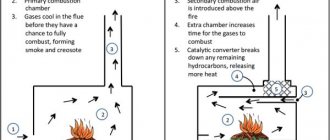

A screw pile consists of a shaft, which can be solid or composite, and a tip. The essence of its application is to, due to turning forces, pass through weak layers of soil and cling to dense, incompressible layers. It is fixed in the ground thanks to the blades; their surface, and not just the trunk, rests on the ground.

Operating principle of a screw pileSource avocet.ru

If we compare the screw version of piles with the driven one, the advantages of the former are obvious when compared from the point of view of the complexity of installation, the presence of noise and vibration. Again, in a small facility you can do without drilling or piling equipment. However, not everything is as wonderful as we would like.

Is the screw base as reliable as is commonly believed?

Pile foundations, including screw ones, are laid in difficult hydrogeological conditions when the strip option is unacceptable. And they must be designed in the same way as any others, with calculations based on load-bearing conditions: soil resistance, strength of piles and grillages material, settlement from vertical loads. Not only does no one do this during self-construction, but it is also almost impossible to find supports of proper quality:

- In pursuit of cost reduction, modern manufacturers remove up to several millimeters of metal from screw piles, which previously served as an anti-corrosion safety margin, and instead provide a cheaper anti-corrosion coating.

- The diameter of the blades was also reduced to a minimum, and since the thickness of the trunk proportionally depends on this size, it also became smaller. In a new format, far from ideal, the pile most often used in low-rise construction has dimensions of 300/108 (blade diameter/trunk diameter) with a wall thickness of 4 mm. By the way, such parameters of screw supports are simply unacceptable in Western countries.

Modern (budget) screw pile formatSource ecodom-kostroma.ru

Excerpt from the documentSource ecodom-kostroma.ru

- However, even today manufacturers guarantee metal piles a half-century service life, although at the same time they have become almost half the price of bored piles - capital, time-tested and very reliable. There must be some catch here!

- And this is what it consists of. It is not worth installing metal supports with modern pile parameters if the service life of the wall material is longer than 50 years (concrete, brick, natural stone). And even a wooden frame, with proper treatment and external protection, can last longer than this “very reliable” foundation.

Reinforced concrete grillage will last longer than supportsSource evroctandart.su

It turns out that building a house on screw piles only makes sense if it is built using frame technology. This foundation design fits into it just perfectly: the load on the support is minimal, and it does not need to “compete” with the walls in terms of durability. First of all, this concerns light outbuildings, for which hardly anyone expects such a long service life.

The feasibility of such a solution is very doubtfulSource www.hebelblok.ru

How to make sure the quality of piles

It was about the general capabilities of the foundation. Now about handicraft production, which is basically impossible to get rid of in our country. Therefore, before you screw in screw piles on your site, you need to look for products of acceptable quality. There is no ready-made recipe here, but we can give some advice on this matter:

It is unlikely that you can purchase high-quality metal piles at a run-down metal warehouse, since their production is a technologically complex process and requires good organization of labor and material support.

This is how blades for piles are cut Source chelny.zoon.ru

If the piles have a minimum thickness - the notorious 4 mm mentioned above, then the manufacturer is obliged to provide reliable anti-corrosion protection. Do not believe if they tell you about the presence of a zinc coating - by definition, cheap piles cannot have it, and installations for its application are in short supply. In practice, other coatings are used (for example, GF-021 primer), sometimes even of normal quality. But you need to be sure of this.

The quality is obviousSource bibliostroy.ru

The next tip again concerns the thickness of the pile wall. It is already extremely reduced, and if you measure this size with a tape measure and find a missing millimeter, refuse the purchase. Because of this, the service life of a house placed on such a foundation can be reduced by 10 years.

Creation of a support-pile foundation

A fairly popular type of base is the support-pile structure. It is durable and reliable, so it is perfect for a stove, bathhouse or wooden building. The process of creating such a foundation is as follows:

- Markings are made on the ground according to the dimensions of the stove with an addition of 10 cm in each direction.

- Use a bayonet shovel to dig up 20 cm of soil.

- Pegs are installed around the perimeter and ropes are pulled.

- In the places where the peg is installed, holes are drilled with a depth of 50 cm and a diameter of 20 cm.

- Formwork is created on the basis of boards, which are connected using nails. It is installed in a pit.

- Along the perimeter of the formwork, polyethylene is attached to its walls. It will help provide waterproofing.

- A 15 cm layer of sand is poured into the bottom of the trench and compacted thoroughly. Gravel is poured on top and water is poured in.

- Reinforcement is knitted based on wire with a diameter of 0.8 mm. It will need to be twisted carefully.

- Piles are installed in the pits. For such purposes, it is best to use asbestos pipes.

- The piles are filled with concrete mortar. It will take about 2 weeks for the composition to dry.

- After the concrete has hardened, you can pour the entire base area. It will also take about 2-3 weeks to dry.

Support-pile foundation for a furnace Source besedkibest.ru

This basis is durable and of high quality, but its creation will take quite a lot of time. If you want to complete the construction as quickly as possible, it is better to give preference to the concrete or rubble concrete type.

Device

The load of the building on the ground is transmitted through a strip foundation installed around the perimeter of the object and under its load-bearing elements, and piles. Both the supports and the tape are reinforced with reinforcement. The installation of the former is carried out using the bored method or using the technology of pouring concrete into asbestos pipes installed in wells. The bored method also involves preliminary drilling of wells into which the supports are immersed.

Screw piles, which have blades at the bottom of the support for screwing into the ground, are also becoming widespread today. The popularity of the latter is due to the lack of need for complex soil preparation.

Driven piles are rarely used, since this method causes ground vibrations, which negatively affects the strength of the foundations of neighboring objects. In addition, this technology implies a high noise level during operation.

Depending on the soil characteristics, stand piles and hanging analogues are distinguished. The first option is characterized by the fact that the structure of the racks rests on solid layers of soil, and the second - the structural elements are suspended due to the friction force between the soil and the side walls of the supports.

Base for a metal stove

A metal heating structure also requires a separate base. The fact is that if the stove does not stand level, this can lead to its deformation and destruction.

The procedure for constructing a base for a stove weighing no more than 150 kg is as follows:

- The trench is marked and excavated. Its depth should be no more than 0.5 m.

- Crushed stone is laid and compacted. The final layer of the pillow must be at least 30 cm thick.

- The concrete mixture is poured. You will need to set aside a day to set it. This solution is made in the following proportions: 1 part cement, 4 parts sand and water.

- After the cement has set, roofing felt is installed. It will serve as a waterproofing layer.

- The remaining space is also filled with concrete, but made in different proportions. You will need to take 1 portion of cement, 4 portions of gravel and 3 portions of sand and water.

- The finishing layer is leveled using a building level.

Metal furnace on a foundation Source sarinform.com

It will also take about 2-3 weeks for such a base to harden. It will need to be moistened periodically.