Log bench

This is an interesting and at the same time quite simple solution, which can have several options. You can do the following:

- Make markings on the log (the lines will run lengthwise), but the cut itself needs to be made with a slight offset, so you will end up with two parts unequal in size. The smaller one will be needed for making the backrest, the larger one will be for sitting;

- cut the log in two and level the surfaces of the parts at the place where they were cut, you should get smooth planes, all irregularities can be removed with a chainsaw;

- If you want to make a bench without a back, follow the diagram below, cut two grooves in the top of one of the logs and place the part intended for sitting in them.

Then the product will look like this:

If you expect to have a backrest, you can adhere to the following scheme of work:

You can also use this option:

Photo source: www.remoo.ru/uchastok/skamejka-iz-dereva-svoimi-rukami/

Manufacturing

It is quite possible to decorate the bathhouse yourself. A bench made with your own hands is a source of pride for the craftsman. Depending on your skills, you can make a simple or two-tier bench. With some skill, you can handle the second option without any special skills, following the instructions. In any case, you will need a diagram and drawings.

Simple shop

If you are a novice carpenter, it makes sense to make a small mobile bench. As you work, you will gain minimal experience, then you will be able to cope with more complex and intricate designs. First, make a diagram indicating all the dimensions (height, length, width).

For manufacturing you will need self-tapping screws, as well as polished ones:

- boards 150×20×5 cm – 2 pcs.;

- bars 5×5 cm – 2 pcs.;

- strips 10×2 cm – 2 pcs.

Let's consider the stages of work.

- Divide the first block into 4 parts of 50 cm each - these are the future legs.

- Divide the second block into 4 parts of 41 cm each - these will be horizontal posts.

- Make 2 frames. To do this, fasten the legs using self-tapping screws with the posts in the upper part. Fasten the lower part of the rack from the inside at a height of 5 cm from the floor.

- Fix 2 planks sequentially on the frames using 4 self-tapping screws. Leave a gap of about 1 cm between the elements. Attach the screws from the inside or deepen them into the wood by 0.5 cm, cover them with putty (otherwise, when warmed up, the screws will leave burns).

- Fix thin strips on the lower crossbar for better stability of the structure.

Two-tier bench

To make such a design you will need a drawing. This is the only way to take into account every little detail and insure yourself against remaking the bench. Working with such a workpiece is much easier and more enjoyable.

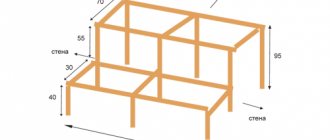

Let's look at how to make a structure 3 m wide, 3.6 m long and 2.4 m high.

- At a long blank wall, install a frame made of 50x70 mm timber.

- Sand 12 pieces of 110cm length and 6 pieces of 90cm length for the top shelf.

- For the bottom shelf, sand 6 pieces of 140 cm length and 6 pieces of 60 cm length.

- Make seats (flooring) from boards approximately 20x120 mm, their length should correspond to the length of the wall.

- For free flow of water and ventilation, leave 1 cm gaps between the boards.

- For the transverse ligament between the posts of both shelves, it is necessary to prepare 3 beams.

- For the upper tier, knock down the racks in a U-shape and connect them with two boards. Using 5x5 or 10x10 cm bars, attach the structure to the wall.

- Knock down the racks for the lower tier in an L-shape. Combine the long sides with the racks of the upper tier. Connect the lower racks together with boards.

- The work on the frame is completed. Now lay the boards on the tiers. To connect, use convenient fastening methods (the best option is wood nails).

Photo instructions on how to make a bench with your own hands

Bath furniture drawings

You can make simple wooden furniture for a bathhouse with your own hands, buy more serious products in a store, you can find the manufacturer’s contacts and buy from him at a lower price (although not a fact) or order a set made to your taste.

Wooden furniture from the manufacturer is, of course, good, but if you built a bathhouse yourself, then you can make furniture: the models are not the most complex, there are many available diagrams and drawings. The most important thing is to carefully process the workpieces: the edges must be rounded, all parts must be carefully sanded, first with a grinding machine, then with fine sandpaper by hand until a perfectly smooth surface without the slightest chips, burrs or other flaws.

Bath bench. DIY drawing

The parts are fastened either the old fashioned way using oak wedges, for which the corresponding grooves are cut out (a complex option that requires experience and time), or using self-tapping screws (nails are less reliable). When assembling bath furniture with your own hands using screws, “recess” the caps to a depth of 5-6 mm. Then fill the resulting holes with wood putty of the appropriate color. With this you kill two birds with one stone: the putty protects the iron from oxidation and dark spots and streaks will not appear on the furniture; moreover, if the items are used for the steam room, the metal parts will not burn the skin.

Do-it-yourself wooden bath table: drawing and dimensions (can be changed proportionally)

The table must be in the rest room. At least small. You need to drink a lot in the sauna. You will need to display teas, infusions and cups/thermoses/saucers. So without a table - nowhere. A drawing of a table that is stable and easy to manufacture is shown in the figure above. There shouldn't be any difficulties. The main connections are self-tapping. Their length is 3/4 of the total thickness of the parts being connected (so that they do not stick out from the tabletop). The diameters are all there, where to screw in is marked. Give it a try. It will work out for sure.

There is one little secret that will make the putty almost invisible: add a little dust to it, which is obtained during sanding. If you have successfully chosen the color, then after this additive the marks after sanding are barely noticeable.

Wooden bench. Can be used for a washroom or rest room in a bathhouse. Easy to make yourself

When assembling shelves for the steam room, benches, tables or other bath furniture, place the boards not closely, but with a small gap. This, firstly, will solve the problem of water drainage - it will flow into the cracks, secondly, the wood will be better ventilated, and thirdly, wood tends to expand/contract with changes in temperature and humidity, and such cracks provide the wood with this opportunity.

Watch this video on YouTube

Conclusions: furniture for baths and saunas should be made of wood. What furniture to buy for a bath is your choice, which depends on taste, habits and capabilities. You can buy a ready-made set, you can order production from a master, or you can try to make it yourself. Any option has its positive and negative aspects, but the most inexpensive furniture for a bathhouse is obtained if you make it yourself. The only thing that can be used with restrictions in the bathhouse is upholstered furniture. In this case, you need an ideal ventilation system that will effectively remove excess moisture from the air.

Watch this video on YouTube

Some interesting ideas that may be useful to you

This set of furniture when folded does not take up any space at all, but looks like a wall panel

On the open terrace near the bathhouse you can make stools like this. Original, just like the tree trunk solution

Log bench with back

If you want your garden to look beautiful, but at the same time do without buying expensive garden furniture, then these instructions will certainly come in handy. Do you have several logs? Turning them into a beautiful handmade log bench is very simple! Here's how to cut, shape and assemble pieces of wood to make the cute little bench you see in the photo. The design is not very sophisticated, but the simplicity of the whole concept makes it attractive. The tools you will need are an electric saw and a drill.

A drawing is definitely not required, because the project is very simple to make. Just use the photos as a guide and make sure the result is similar to what is shown here. Decorating your garden with unique handcrafted furniture like this one will definitely enhance the overall design.

Photo source www.goodshomedesign.com/diy-decorative-log-bench/

Material

Wood is a capricious material, or rather, sensitive to how it was prepared and dried. Therefore, you need to not just take the first board of a suitable species that you come across, but take a closer look at it, and, if possible, measure the humidity.

IMPORTANT! Because a tree that is improperly dried after cutting and cutting will definitely warp—it will “lead,” that is, it will either change its geometry or twist it.

When inspecting boards for carpentry, of course, first of all look at the number of knots. They are known to cause a lot of problems for woodworkers.

Also pay attention to the dimensions. Boards can be very uneven - both due to uneven shrinkage and due to cutting too quickly. The reasons may be different, but you will have to adjust it to the desired size later.

ON A NOTE! The presence of mold, rot and cracks on the purchased material is unacceptable!

And since we are telling you about benches for a bath, we need to clarify in a separate paragraph which types of wood are best suited for such purposes.

Steam room

Resin leaks

If the bench will be in a steam room, then immediately discard coniferous wood. They begin to secrete resin at temperatures above 40 degrees.

Deciduous ones are fine. For example, you can take aspen, linden, poplar, ash.

Washing

There are no high temperatures in the washing room, but the water flows generously. This is where you can use conifers - it’s the resins that make them more resistant to high humidity and prevent them from rotting.

Take the same pine - it is the cheapest. All others are also suitable - deciduous ones are also possible if you use water-repellent impregnations.

Rest room and dressing room

There are no restrictions on wood - make it from what you feel like. Humidity will be high here too, but you can freely use both impregnations and varnishes. So the choice is yours.

How to make a bench with your own hands for a bathhouse

To make a regular portable bench for a bathhouse, there is no need to assemble a special frame. This design option is distinguished by its simplicity and ease of use.

Material selection

Only a certain type of wood is used to make bath benches. Due to the high resin content in pine, which begins to actively release under the influence of high temperatures, this type of material loses its relevance. Iron hornbeam is also not used, although it has a high level of resistance to water and moisture. Its significant disadvantage is the strong heating, which leads to burns on the skin.

Among all types of wood, it is better to give preference to:

- Linden. It practically does not heat up even in a sauna and is resistant to steam. The material has a pleasant smell, but after a while it begins to darken.

- Aspen. Its resistance to steam and water is an order of magnitude higher than that of linden, but it is inferior in smell. This variety is the most mediocre in terms of attractive appearance. Aspen is valued for its resistance to mold.

- Larch. It is noteworthy that wood under the influence of steam and water only becomes stronger and can last for ten years without changing color or texture. The disadvantage of the material is its high cost.

- Cedar. This representative of coniferous species releases resin in minimal quantities when heated. It is chosen for finishing steam rooms and making benches due to its positive effect on the lungs and the entire human respiratory system. Cedar is especially useful for people suffering from asthma, bronchitis, and lung diseases.

- Oak. This type of wood has proven itself well when used as a material for making bathhouse benches. Oak has increased resistance to water and steam, and has high decorative qualities, but products made from it are best used for dressing room equipment. Given its density, it gets very hot in the steam room.

- Birch. It is used to make benches for bathhouses because of the medicinal tar released when heated. Thanks to its healing properties, it is possible to treat even the most contagious skin diseases.

To make a bench you will need:

- wooden beam with a section of 6×7 cm;

- slats 2-2.5 cm thick and 6 cm wide (for the seat structure) in the amount of 9 pieces;

- fasteners made of wood or metal.

When decorating a bathhouse, it is not necessary to use the same material for finishing the walls and making the bench. But the option in one style looks more impressive, although playing in contrast also has its own originality.

Required Tools

To carry out the work you need to prepare the following set of tools:

- saw;

- hammer, mallet;

- pliers;

- screwdriver;

- sander;

- roulette;

- level.

Advice! It is important to prepare all the tools in advance so that you don’t get distracted when making a bath bench.

Bench manufacturing technology

Step-by-step instructions for a do-it-yourself wooden bench for a bath include the following steps:

- Cutting the timber into 4 fragments, each 40 cm long.

- Assembling U-shaped racks. Two pieces of timber 60 cm long need to be knocked down to form transverse jumpers.

- Cutting according to the specific length of slats for making a seat. It is optimal to use slats with a length of 160-170 cm.

- Assembling the bench. The prepared slats need to be stuffed onto the jumpers, avoiding a gap of less than 1 cm between them. This is necessary to remove excess moisture and to expand/contract the natural material when exposed to temperature changes and high humidity. In addition, it is recommended to retreat 20 cm from the edge in order to achieve increased stability of the structure.

- Bench strapping. To create a strong bench, the legs and stands need to be connected using the remaining slats, 10-15 cm away from the floor. Special corners are also suitable for these purposes, but it is advisable to attach them from the inside of the product, otherwise a burn will appear on the skin at the point of contact. That is why it is advisable to recess the fittings used in the manufacture of the bench by 2-3 mm.

Finishing and decor

The finished bath bench must be treated with a natural-based antiseptic composition. If you want to make it in country style, then you need to adhere to the following algorithm of actions:

- Sand the surface along the grain with a brush.

- Clean with a grinder until a relief pattern is formed.

- Apply translucent glaze in two batches.

- Wipe the surface with a dry sponge; when it dries, remove the glaze.

- Cover the bench with varnish.

Making and giving the bench the desired appearance is quite simple if you follow all the recommendations regarding assembly and finishing.

Wood requirements

To make a bench for a bathhouse with your own hands, you need to take a responsible approach to the choice of wood; it must meet the following requirements:

- have a high degree of density, otherwise the product will simply crack during use;

- have a low level of thermal conductivity, otherwise when heated the material will pose a serious danger to the health of the visitor;

- have sufficient resistance to moisture so that the service life of bath furniture is longer.

As for the sauna benches themselves, all wood used (bars, boards) must be carefully sanded. For these purposes, sandpaper of different grain sizes or special machines are used. All existing corners must be rounded. In addition, bath furniture should have high strength characteristics and withstand the weight of several visitors, not just one.

To impregnate wood, it is not advisable to use synthetic-based compounds, which release toxic substances at high temperatures. To treat the bench, it is better to purchase natural impregnations.

To prevent damage to furniture due to high moisture, you should not sew up the space under the bench - this way the quality of drying the material will be much higher. A gap of 10 cm should be maintained from the wall to wooden furniture. It is not recommended to use paints and varnishes for processing interior items.

Garden bench made of logs

In every garden you can find a place to install a bench. Of course, I want it to be a beautiful and original design. To create a relaxing seating area, make a garden bench from a log. I don’t know what about beauty, but this is an original, and most importantly, durable and reliable bench that will last a very long time. A short instruction will help you easily cope with this task. If everything works out, you can also make a small bench, for example, for children.

What you need:

- For the backrest: 2 posts (length according to desired height), 1 board (approx. 120 cm in length)

- Part of a log, diameter about 30 cm

- 2 leg trims, length and diameter approximately 30 cm

- Chainsaw

- 12 screws, approximately 150 mm

- Drill

Step 1. Secure the log with wooden wedges. First mark the cutting line at the front, then along the longitudinal sides. Cut the saddle with a vertical cut to the middle of the log. Turn 180 degrees and make a cut on the other side. Step 2: Make the legs. Adjust the two short pieces of log to fit the saddle with a V-shaped notch and fasten with screws. Step 3. Screw the backrest crossbar to the bench and legs. Step 4. Screw the backrest board to the supports at the desired height.

Photo source unicommerce.si/novice_in_nasveti/nasveti/strokovno_znanje_za_vas_vrt/delo_z_motornimi_zagami_stihl/tako_izdelate_vrtno_klop/

If you are already making a bench from a log and you have enough material left, you can also make a flower bed like this in a log - a special charm for every garden. Just don’t forget about safety precautions when working with a chainsaw. When working, you must wear personal protective equipment. Wear hard gloves, preferably chrome leather. Wear trousers with leg protection and sturdy, rough-soled shoes that have a steel cap and rubber insert. But remember: personal protective equipment and accessories are no substitute for careful and safe work.

Therefore: read the operating instructions first and then get started!

What you need:

- log with a diameter of 30-35 cm

- 2 small log cuts about 30 cm long, 20 cm in diameter

- 4 screws, approximately 150 mm

- electric saw STIHL

- axe

- drill

The instructions can be read on the website, below are step-by-step photos.

Photo source unicommerce.si/novice_in_nasveti/nasveti/strokovno_znanje_za_vas_vrt/delo_z_motornimi_zagami_stihl/tako_izdelate_korito_za_cvetlice/

Log bench for a summer residence

This, of course, is not the most attractive bench in aesthetic terms, but it is simple and reliable. It's very easy to do.

- Splitting a log and cleaning the surface is not a problem. The most difficult task is to attach the legs correctly.

- First, draw some sketches to better calculate how to attach the legs to the bench.

- Then drill holes where they will be installed.

- Fill the holes with glue and insert the legs.

- Make a mixture of glue and sawdust. Fill the void between your feet and the bench with this mixture.

- When the glue has completely hardened, your bench is ready.

Photo source www.instructables.com/id/LOG-BENCH-1/

Which type of wood to choose

The material for benches in the bathhouse has strict requirements:

- high fiber density, which prevents the wood from splitting and cracking;

- low thermal conductivity, ensuring a comfortable temperature of the wooden flooring;

- resistance to moisture, allowing long-term use of furniture in difficult conditions.

It would seem that coniferous types of wood are suitable for a bathhouse: larch, pine, cedar, but they have a significant drawback that precludes their use for furniture in a steam room. When heated, resin appears on the surface of the boards, such secretions leave burns on the skin, so moisture-resistant coniferous wood is used for benches in the rest room or in the washing room.

Linden has become a favorite among materials for furniture in the steam room: it is easy to process, resistant to water and heat, and smells pleasant. Aspen is also good, but over time the wood begins to rot from the inside. Oak does not cause any complaints - this material has many advantages, but its cost is high. Benches can also be made from other types of wood: maple, poplar, birch.

Before making benches in the bathhouse, you need to find out the requirements for their design.

- Boards and beams used to make furniture for the bathhouse must undergo thorough sanding of the entire surface with a special machine or sandpaper.

- The corners of the benches must be rounded to avoid injuries and scratches.

- Furniture must be durable and reliable, designed for safe use by an adult.

- For antiseptic impregnation, it is prohibited to use synthetic liquids that release toxins when heated. The material is protected with special compounds based on natural oils.

- For better drying, the space under the bench is not sewn up.

- A gap of up to 10 cm must be left between the wall and the installed bench.

Preparing for the construction of a wooden bench

If you need instructions describing how to make a bench, then start with the preparatory stage. First you need to decide where the bench will be located, if it is stationary, or where it will be needed.

Next you need to work on the drawings and dimensions for making the bench. Here the Internet or thematic magazines can come to your aid. One way or another, mistakes at this stage can greatly affect the overall result of the work - we are talking about an uneven surface or a banal skew of the bench.

In addition, documentation is also needed in order to more accurately determine the required amount of materials.

Choosing a tree for a bath

There are many types of wood, but not all of them are suitable for saunas and baths. There are certain requirements that the material must meet:

- low thermal conductivity;

- ease of processing;

- absence of cracks, knots and resin pockets;

- high density.

Conifers containing resins can only be used in the wash room, dressing room and recreation room, where there are no high temperatures. The exception is Canadian cedar, which has a low resin content and a very attractive texture. In all other cases, steam room furniture is made exclusively from hardwood - ash, linden, oak, aspen, poplar, alder and others.

Characteristics of wood

The wood must be dry, dense, without cracks or other defects, with a smooth surface. The higher quality the lumber, the longer the furniture will last. Raw boards are more difficult to process, and finished products become deformed when drying.

Texture of different types of wood

Preparing for assembly

Before you start working on making a bench. We need to check the availability of tools. You should always have at hand: a hacksaw, a drill. It would be nice if you have a screwdriver. You definitely need a tape measure, a pencil, a square, a hacksaw, wrenches, a brush, and sandpaper.

If you decide to build a wooden bench, then you need to purchase materials:

Boards. Having dimensions of 100X40mm and 100X25 mm, you will need furniture screws with 8 - 10 mm threads, nuts, and self-tapping screws. Wood putty will also come in handy.

Be sure to purchase antibacterial protective impregnation. Once you have chosen the location of the bench, you need to draw up a work plan for its installation.

Select the size of the bench, decide how the back will be attached, plan the placement and fastening of the legs. Dig holes of the required size in the ground, place the legs in them, level them and fill them with cement mortar.

We draw up a drawing of the drawing, indicate the dimensions on it, and get to work.

How to protect wood from moisture and rot

If such a bench is intended for a steam room (although this is rare), then we recommend treating it from waterlogging (and subsequent cracking when drying) with those impregnations that contain oils and wax. In particular, you can purchase products from Tikkurila for this - they have developed compositions specifically for furniture in the steam room (we gave the names in the article about benches).

ADVICE! It’s still not worth covering the furniture in the steam room with an antiseptic. All antiseptics are poisonous to humans. There are heat-resistant varnishes that are marketed for the steam room and even for the stones in it. It's up to you to choose. We remain of the opinion that polishes have no place in the steam room.

We recommend making washroom benches from coniferous wood and covering them with moisture-repellent compounds. In principle, here you can already use an antiseptic under a layer of water-repellent impregnation or varnish.

In all other rooms it is not so humid, but still the humidity is higher than in the home. Therefore, impregnations and varnishes are recommended for use. There are no restrictions.

DIY wooden bench with backrest

A comfortable garden wooden bench with a back and a drawer is perfect not only for relaxation, but also for storing watering hoses, pots, tools and other equipment.

Briefly about the manufacturing procedure.

- Make the legs first by cutting the 1x6 boards at a 45° angle so you have 2 long halves.

- Pin and glue together at the beveled edges to form 4 legs.

- Assemble the box by attaching the boards to the legs.

- From below, inside the box, make a frame on which the mesh will be attached.

- Install a net at the bottom of the bench

- Make a seat and attach the hinge

- Attach the back with screws. You can make it square or rounded, whichever you like best.

Below are detailed photo instructions

Photo source www.instructables.com/id/Outdoor-Bench-With-Storage/

This is important to know: useful recommendations from experts

To ensure that your homemade bath furniture is reliable and lasts a long time, it is important to consider the following recommendations from experienced craftsmen:

- The boards of wooden benches for a bathhouse must be carefully sanded and their edges rounded, which will help eliminate the risk of injuries and splinters.

- It is strictly forbidden to use conventional oil-based varnishes and paints for bath furniture in a steam room, since when heated they release harmful toxic substances.

- It is undesirable to make furniture in a bathhouse from coniferous wood, since the released resins, although useful, can cause a burn if they come into contact with the skin.

- When choosing fittings, preference should be given to wooden fasteners.

- Ventilating the steam room after bath procedures will reduce the risk of mold and dampness, and will also extend the life of wooden furniture.

- The space between the floor and the lower bench should be left open, which will also promote better evaporation of moisture and prevent rotting of furniture and walls.

Now knowing which wood is best to choose for bath furniture and how to make benches and benches yourself, you can safely arrange your ideal steam room!

How are there species?

There are a large number of benches with a back, and each owner of a country house or dacha chooses for himself the option that is most suitable for the exterior of his personal plot.

Benches come in a variety of varieties depending on their scope of application.

- Ordinary benches with a back are suitable for any personal plot and will fit perfectly into the exterior of the yard. They are comfortable and very practical, as they have a simple design and are unpretentious in appearance. Suitable for installation near the house, in a gazebo, near a pond, etc. They can be made of wood, metal, stone, and also be combined (wood and metal, wood and stone, wood and brick, plastic and other building materials).

- Corner benches will look great where you can’t put a regular large bench with a back. They can be placed in the corners of the gazebo, in gardens, as well as in any convenient place in the garden. Such benches can be metal, wooden, stone or combined.

- Ordinary benches without a back can be installed anywhere, as they are universal and convenient enough for any country house. They can be easily made with your own hands, since they are made according to the most common standard drawing of the classical type.

- Oval, round or semicircular benches with and without a back will look great in the center of the same round gazebo, in the center of the garden or in another place where they will create an aesthetic exterior for the entire garden plot, as well as perform their direct functions. Also, in the center of a round bench there can be a tree, a green bush, a beautiful flower bed blooming, or even a children’s sandbox. Here everything depends on the imagination of the master and the functional needs of the owners of a country house or dacha. They can be made of wood, metal, stone, and also in a combined form from various natural materials compatible with each other.

Photo gallery: DIY garden benches with wooden backs - types and designs

Wooden bench with metal legs for the garden

Wooden bench with forged metal legs for the garden

Corner wooden bench with brick support

Semicircular wooden bench on a brick support

Bench made of wooden beams for the garden with a back

Decorative wooden bench for the garden with supports made from flower boxes

Classic wooden garden bench with handrails and backrest

Round wooden bench with back for the garden

Original bench made from solid logs for the garden

Wooden bench on supports made of natural stones for a personal plot

Wooden bench with concrete supports in the form of flower beds

Wooden bench with wooden supports in the form of flower beds

Wooden bench with wicker back for the garden

Stone designer bench for the garden

Homemade portable bench design

A portable bench without a back is the simplest and most affordable option for homemade bath furniture. It does not require installation to a special frame and can be used in a steam room, washing room and dressing room. Surely many will be interested in how to make a bench for a bathhouse out of wood with your own hands.

When making a sauna bench, an important step is the selection of a working drawing and assembly diagram.

You can develop drawings and diagrams yourself or look at our ready-made examples. They indicate the length, height and width of individual structural elements.

To assemble a sauna bench yourself, you need to prepare the following materials:

- bars for legs with a cross section of 5 cm - 4 pcs.;

- bars for struts and crossbars;

- wooden board 5 cm thick of the required length and width - 1 pc.;

- metal or wooden fastening fittings.

All work is performed in the following order:

- In the blanks for the legs, mortises are made on the inside to fix the crossbars made of timber.

- A crossbar is attached to each of the prepared legs using self-tapping screws.

- A seating board is mounted on top of the resulting structure.

- The struts are fixed to the crossbars and the seat with self-tapping screws.

Now the portable bench for the bath, which we assembled with our own hands, is ready for use. After assembly, the product is treated with a protective antiseptic composition.

Knowing how to make a bench for a bathhouse, anyone can show ingenuity and imagination in order to make a practical and functional product without much effort.

Drawings for further work

Any construction should begin with the development of a drawing plan. The drawing should show the following parameters and dimensions:

- First of all, you need to make a list of all the available parts for the job.

- Next, you need to indicate the dimensions of the future bench: the width of the seat, the height of the backrest and its angle of inclination, the dimensions of the side slats, the height of the support legs.

- The drawing indicates the shape and dimensions of the frame for this model.

- The presence of fasteners and their location on the model must be indicated.

After the prepared sketch, an accurate calculation of the required material should be made in order to eliminate unnecessary financial costs. A carefully drawn up drawing of a bench for a summer house allows you to carry out the work consistently and without gross errors.

Photo

Carved bath bench

Furniture for the rest room

Furniture for the bathhouse

In the washroom With an unusual design Bench with stool Stationary benches Functional box bench

Benches as shelves Bench stylized as a log house

Benches and table in the bathhouse

With diagonal boards

Homemade wooden bench

Did this article help you?

How to make a small bench?

You can make a simple and comfortable bench with your own hands from any available materials: from old furniture, from a terrace, from a floor or even from an unedged board. And use the scraps to build additional parts, for example, crossbars to enhance the load-bearing capacity or additional shelves. A step-by-step diagram of a simple project that even a beginner can handle - a small bench consisting of two legs and a seat.

- First, you need to cut 3 parts from a wide board, that is, cut it into 3 parts: a seat and 2 legs. The seat should be 96 cm long and the legs should be 38 cm.

- Now you need to create decor on the legs. The first stage is to cut a groove in the middle of both parts. The second stage is to drill a hole of any convenient diameter in the center. Holes are also made in two parts.

- The next step is to create support in the racks. To do this you need to make an arch. First, a sketch is made in pencil, retreating 4 centimeters from the edge, then cut out with a band saw and sanded. The arch for the second rack can be made using the first one as a template.

- Now you need to cut out additional crossbars.

- On the future seat, for convenience and aesthetic appearance, bevels should be made along the edges - chamfers.

- The preparation is complete, now you can start assembling. First, you need to connect the crossbars and legs using screws - you get a kind of frame. Holes for screws should be prepared in advance using a drill.

- The last step is to screw the seat to the frame.

Making shelves in the steam room - step-by-step instructions + Video

A standard steam room shelf consists of two parts: a seat and a support stand made of durable timber. The latter consists of two beams placed along the seat and connected to each other. The boards that are placed on the frame must be thin, and the distance between them is usually one or two centimeters.

Making shelves in the steam room with your own hands

When making shelves, attention should be paid to fastening parts. In this case, it is extremely undesirable to use screws or nails, because if they come into contact with them, a person can get burned.

Stage 1. Decide on the size of the steam room

The bench for the steam room must be at least 1.5 meters. Regarding the size of the shelf, they will all depend on the dimensions of the particular bathhouse. However, its top step is in any case the largest - about 0.9 meters, while the rest are from 0.4 to 0.6 meters.

Optimal dimensions of a shelf for a steam room - diagram

The height of the shelves is determined according to the following criteria: a person must be comfortable both lying and sitting. It turns out that the distance between the ceiling and the top step should be at least 1.2 meters.

Stage 2. Select wood for the steam room

The bath shelf is an extremely important element, because it comes into direct contact with human skin

Therefore, the choice of wood for its manufacture should be given due attention. So, let's look at the options:

1. Linden is ideal for our purpose. It is easy to process, it does not crack and smells quite nice. Moreover, linden is known for its healing properties, and is relatively cheap. The only downside is that at high temperatures it loses its original color over time.

Steam room in a bathhouse made of linden

2. Aspen also has healing properties. Due to its low cost, as well as its ability to “suck” all the negativity out of a person, it is quite popular today. There is also a drawback: aspen begins to rot from the inside, so it is extremely difficult to distinguish high-quality wood from low-quality wood by eye.

Aspen as a material for a bath

3. Abashi is a tree native to sunny Africa, which has a number of beneficial properties. It is resistant to high temperatures and moisture. During use, the color of the wood practically does not change. The only negative is the cost of Abashi.

Abashi - material for finishing baths

Stage 3. Build the frame

The manufacture of the shelf must begin with the construction of a wooden frame; for this we will use beams, to which we will subsequently attach boards. We will need five racks and, accordingly, ten bars. The beams are fastened to each other with the same beams, and to the racks with special screws, two for each piece.

For flooring we will use boards (the gap between them should be at least two centimeters). So, the bottom shelf requires three boards, and the top one requires seven boards. Their approximate length is about 2.96 meters (this is explained by the fact that some gap should be left between them and the walls, because then you will have to cover them with clapboard).

Frame for a shelf in a bathhouse - photo

Stage 4. Connecting the frame

To connect all the parts, oak wedges are used, which must be driven into pre-made holes. At the same time, many builders avoid such a troublesome procedure (meaning fastening without using nails), resorting instead to traditional self-tapping screws, but with deep recessing.

Connected frame for a bath - photo

In any case, the bottom shelf should be movable - this simplifies further care of it. In most cases, it is made in the shape of a triangle, which allows for maximum compactness in the room.

The free space that remains between the levels is usually left open, but you can additionally install backrests there, preferably made of pine needles (it has healing properties).

Stage 6. Regimental defense

This is the final stage of our work. If you do not treat the wood with chemicals, it will soon become unusable due to constant contact with moisture. Rot or mold forms; this can only be prevented with timely prevention.

Drying oil or varnish are unacceptable for this purpose, since under extreme conditions they emit an unpleasant odor and can lead to allergies. It is better to use natural impregnation, which is freely sold in most stores. It has excellent characteristics and should be used to cover all surfaces of the bath.

Common mistakes when creating a bench

The work is not without mistakes, which is especially important for inexperienced craftsmen. Accounting and detailed analysis of erroneous actions is necessary in order to avoid similar situations in the future. Errors that may occur at any stage of work:

- Selection of low-quality raw materials. The presence of defects on the surface and improper storage of timber can lead to unnecessary financial costs, loss of personal time and a reduction in the life of the bench.

- The product can easily be damaged by high humidity (weather conditions), pests and fungi if the wood has not been treated.

- No sanding of surfaces and edges of wooden blocks. Sharp edges and jagged edges can injure people, especially children's delicate skin.

- Another possible mistake may be related to incorrect design of benches with a back. An insufficiently modeled angle of inclination will lead to pain in the back and muscles in the future. It is simply uncomfortable to sit on such a bench.

- Poor quality assembly of the structure. Using only self-tapping screws during the work process may not be enough. It is better to additionally treat the joints with glue, and lay metal corners along the outer surface.

- Irregular shape of supporting structures. The support must be made not only of high quality, but also taking into account the shape. To properly distribute the applied load on the bench, the frame must have supports of sufficient width.

The location of future garden furniture plays a very important role. The soil should be of sufficient density, or even better, prepare a small base for installing the bench. It is better not to install a bench, which is intended primarily for relaxation, near the economic zone and areas with unstable soil.

After a detailed study of the methods and techniques for making garden benches for a summer residence, the appropriate conclusions can be drawn. To create a convenient and most practical model, you should carefully study the options available today, prepare a high-quality drawing and select materials. A beautiful and comfortable wooden bench for your garden, made by yourself, will pleasantly surprise your guests.

Care instructions

In order to extend the service life of the bench, you should adhere to the following tips:

- wipe dry both the seat and the back of the bench after each procedure;

- regularly ventilate furniture;

- periodically treat wooden benches with oil or oil wax;

- if there is contamination, use warm water with laundry soap, but aggressive cleaning agents should not be used due to the active chemical compounds in their composition.

If traces of mold or mildew are detected, the affected furniture elements must be replaced.

In addition to care recommendations, you need to know that when making wooden sauna benches with your own hands, the surface should be sanded to perfection. To avoid injury and splinters, all corners must be rounded. It is advisable to use fastening elements not made of metal, but of wood - dowels. A good prevention against rotting and fungal development is the gap between the furniture and the floor. Otherwise, dampness will begin to accumulate in such places, which will cause damage not only to the bench, but also to the walls.

Purpose and types

The bench can be portable or stationary. The size of the structure depends on the dimensions of the specific village bathhouse. The universal height is considered to be 60-70 cm. If a multi-tier structure is made, the distance from the ceiling to the top point of the bench should be at least 1.2-1.3 m.

Most often, portable benches are smaller in size than their stationary counterparts. There are many factors to consider when choosing the type of shop. The purpose, size of the room and the expected number of visitors matter. Based on the type of construction, benches are divided into several types.

Single-tier

More often these are mobile structures for small steam rooms. This option is very convenient - you can easily move the product to any place. You can take the bench outside for drying or minor repairs. This design can be flat (linear) or angular. It's great for a locker room. A single-tier bench is easy to make and easy to maintain. This is an excellent manufacturing option for beginners. You don’t need any special skills to make it yourself.

Bunk

This bench can be placed in a larger bathhouse. Typically, the width of such a bench allows a tall adult to lie quietly. To access the second tier, a special ladder is provided. Such benches are installed along blank walls without windows or ventilation holes. If you do otherwise, drafts will occur.

Three-tier

These designs are designed for rooms with large dimensions

It is important to maintain the proper distance from the top bench to the ceiling. Such a bench is relevant in a steam room: you get the opportunity to choose the desired air temperature (it is hotter on the highest bench). The middle tier is made stationary, the other two are made mobile

The distance between the tiers should be at least 1 m. The lower bench is made smaller (up to 60 cm in width and no more than 95 cm in length). The remaining tiers of the structure may be larger

The middle tier is made stationary, the other two are mobile. The distance between the tiers should be at least 1 m. The lower bench is made smaller (up to 60 cm in width and no more than 95 cm in length). The remaining tiers of the structure may be larger.

Stepped

This model is designed specifically for rooms with small dimensions. The lower part of this structure is usually used as a step. You can sit on it, and you can use it to climb higher. The upper tier should be large; it allows an adult to lie down.

Finishing and decor

Already sanded boards and bars are placed into the structure, so the surface of the finished benches is subject only to finishing. They use special compounds that give a beautiful appearance and extend the life of wood in difficult conditions.

There are many natural-based products on sale for painting benches in a steam room. Natural products are most suitable, since the coating will be affected by high temperature and humidity. Painting is carried out before the bathhouse begins to operate. This way the composition will dry and harden under gentle conditions, which will increase its strength.

How to do

The design itself is simple, allowing for various modifications, including complete simplification, when everything is done without tenons and grooves, simply cut to connect the planes and mounted on long self-tapping screws (just remember that in the bathhouse you should not use self-tapping screws, which can rust ).

What tools will you need for the job?

miter saw with miter box or adapter

You can drill with either a drill or a drill press.

The easiest way to select a tenon and groove, of course, is with a router, but you can also do it the old fashioned way - with a chisel. If you don’t have the equipment and the desire to tinker, simplify the design.

Well, we will still need to sand everything, which can be done with a sanding machine, or with a grinder, or with sandpaper on a block - we’ll sand it with whatever we have.

Instructions

The only material needed is a board 50x100 mm at the end. Recommended wood: oak, aspen, larch, pine.

Depending on the length of the bench, the number of supports may be more than two. Therefore, calculate the consumption yourself based on specific dimensions.

The triangular support consists of the following parts: horizontal, vertical and connecting strips, as well as a wooden dowel with a diameter of 12 mm and a length of 100 mm connecting the structure.

Above are drawings of each of the planks. Following them, you will cut the board, make grooves, and then make holes for the dowel. By the time of installation, all parts must be sanded.

Then, from the prepared parts, we select a vertical strip and fasten it with self-tapping screws directly to the wall where the bench is planned. Probably there is no need to say that the height should be the same

The distance between the supports is determined by the length of the bench.

Next, the horizontal and connecting strips are attached to the vertical strip using dowels. Of course, with glue.

Making a seat should not be difficult - we assemble it from our boards, the width of which is 100 mm, not forgetting the gaps if the room is damp. (Gap 1-1.5 cm.)

The seat is attached to the supports either using self-tapping screws or wood screws. Of course, you can put it on glue and dowels. But for the dowels you need to drill holes in both the support and the seat.

That's all. The bench turned out to be stationary, quite durable and strong (50 mm thick is very good). There shouldn't be any problems making it.

Bath bench: design features

The bench in the bathhouse is somewhat different from the usual one.

Firstly, its width and length are determined by the number of bathhouse users, their height and build. Secondly, such products involve the arrangement of several tiers, which is unusual for ordinary benches. Important! Hot air and steam in the steam room accumulate under the ceiling. On a 3rd tier sun lounger it will be noticeably hotter than on the lowest one. This point should be taken into account when planning the steam room and arranging benches.

There are 2 options for sauna benches - sitting and lying. The dimensions of the sauna bench depend on the purpose and the position that the steamers prefer to use:

- the minimum seat width is 30–40 cm for a sitting bench, for a more comfortable position 60 cm is recommended, and 80–90 cm is required for a lying bench; the value in the latter case may be greater: this is the width that a person occupies while lying down and placing his hands freely;

- the width of the step of the lower bench must be at least 40 cm;

- the distance between tiers is from 40 to 60 cm. As practice shows, the optimal range is 45 cm, the minimum distance from the floor of the bathhouse to the desired tier is 40 cm;

- a bench for a bathhouse is made with your own hands of a certain length, and the size is determined by the preferred position: in a sitting steam room, the length of the bench is equal to the width - at least 40 cm for each user, a 60 cm long option is more convenient; for sitting with bent knees, 90 cm is required, and for lying down, but with bent knees - at least 150 cm; The length of the bench for lying is 180–210 cm and is calculated according to the height of the tallest user of the steam room.

The size of the bathhouse benches depends on the location. If the benches are straight and placed along opposite walls, all of the above factors are relevant when determining the size. But with an L-shaped arrangement of benches, you can save on space.

Ergonomics

Ergonomics is the science of how to make things and processes comfortable for humans. In this case, we are talking about ensuring that the seats in the bathhouse do not cause inconvenience due to their size.

Of course, much when choosing sizes will be dictated by the size of the rooms themselves for which you are planning to make benches for a wooden sauna with your own hands. But the height of the seat is a point that is of great importance, but depends little on the size of the room.

It is preferable that the seated person's knees are not raised relative to the pelvis, so the seat should not be too low. However, too high is also uncomfortable - your legs will dangle in the air without support, which increases pressure on the vessels under the knees and in the hips. Therefore, we can proceed from the height from the floor to the knee bend of adults.

Various ergonomics manuals advise making the height from 30 to 50 cm. We believe that it is easier to derive the arithmetic average from the measurements of the people who will most often use this bathhouse.

The width of the seat depends on how they will sit on it - if they sit as usual, then 30-40 cm is enough, and if reclining, then 60 cm.

Those benches on which the steamer will lie must be long enough to accommodate him at full height, and also wide enough so that he can freely place his arms along his body. It is also better to measure such things on specific people.

BY THE WAY! Adherents of the Russian bath should remember that the height of the upper shelf on which the steamer lies is about 85 cm, and the shelves cannot be covered with clapboard to the floor, because the steamer’s feet are located under the bench or shelf.

Before introducing you to the drawings, we recommend that you take a look at our other material, which describes in detail all possible types of benches.

Benches made of boards

The most popular option is benches made of boards. There are quite a lot of execution options. There are even designs that look like sofas. If you put soft pillows on them, you can lie down.

This garden bench is more like a sofa: if it is of sufficient size, you can lie down

Garden furniture designs, based on a modern approach, are assembled simply. As a rule, they consist of rectangles with partitions made of thinner wood, connected together into one whole.

If you stretch your imagination and put it to work, you can build a work of art from an ordinary bench if, for example, you install wooden wheels instead of legs and armrests.

A bench made of boards with a back and wheels instead of sides - looks interesting

One of the simplest designs of a country bench consists of one board, to which legs are attached in the shape of the letter “X”. Our ancestors built similar shops, although they can still be found today.

Traditional bench design

Using wood, you can build a bench in the shape of the letter “P”

In this design, it is very important to ensure reliable fastening of the seat and legs. This option involves the use of a thick board or timber for reliability.

As an option, you can install the board “on edge” for greater rigidity, and for greater reliability it is recommended to fasten it using metal corners.

This photo shows an option where the cut is made at 45 degrees. This is not difficult to do with the help of a special tool. If you connect all the parts, you get an angle of 90 degrees. If the board is thick and the seat does not sag, then the bench will last quite a long time.

In the photo below you can see another option for an interesting solution, which is characterized by increased reliability. Boards of different lengths are used as legs. The difference in length is the thickness of the board: every second board should be shorter. The structure is connected using nails. Moreover, through one board, the nails are driven either into the board for the seat or into the board for the legs.

Modern style bench

Types of wood used for benches

Corner bench for steam room

Raw wood immediately after cutting and cutting will warp under the influence of high temperature, the products will change geometry and become distorted. The moisture content of the material at the time of manufacture should not be higher than 15%.

When choosing a board, lumber with fallen, knots, and darkened areas is rejected. The number of knots also plays a role in smooth wood processing. The purchased boards should be free of rot, mold, and microcracks.

The type of wood is selected based on its thermal conductivity, the moisture resistance of the species is taken into account, and attention is paid to the strength and hardness of the material.

Linden

Linden wood has antiseptic properties

One of the classic wood options for furniture in a steam room, heated linden releases a pleasant honey aroma. Pliable rock belongs to the category of soft materials, and therefore requires pre-treatment to remove moisture. Linden spirit is considered a natural antiseptic.

Wood does not conduct heat well, so at high temperatures you can lean against it without the risk of getting burned. The products breathe, that is, they allow steam to pass through. Linden wood can increase the secretion of sweat, which is important for a bathhouse. The disadvantage is the ability of the material to darken over time.

Birch

It belongs to the group of medium-density rocks, does not heat up when heated, and resists moisture absorption. Durable material is well suited for benches. Requires ventilation from time to time, so it is preferable to make small wooden benches. Old tree trunks are more difficult to process.

There are about a hundred species of the species; pubescent and silver birch are used for the bath interior. The beautiful color varies from light brown to light yellow, sometimes with reddish colors. The aroma has antibacterial properties; the tree does not emit resinous components.

Pine

Pine releases a pine aroma at high temperatures

Available and inexpensive material of medium density. A bath bench made of pine wood is not built in the steam room, but is placed in the locker room and dressing room, since it releases resinous substances at temperatures above +40°.

The temperature in the washing room and shower is not high, so the resins in the wood prevent moisture saturation and prevent rot and mold from developing. Thermal conductivity is low, wood maintains an acceptable level of comfort when touched. It is easy to saw, plan, joint, glue well, and join with nails and screws. For finishing, stain is used to reveal the design.

Exotic wood varieties

Meranti. Wood color - red, density 610 kg/cm3. Due to the heavy and dense wood, meranti does not heat up and can withstand temperature and humidity changes well. The wood is smooth, non-fibrous, practically free of knots, and easy to process.

Additional functionality – awnings over benches

If there are no shady areas on the site, then an additional canopy can be provided for protection from the sun. Let's look at several options for its implementation.

The canopy can be installed separately or made part of the structure, as in the presented photo. Here we see 4 racks made of timber, on which the top trim is made. The roof is formed by boards installed on edge - the classic form of a pergola. Lath trellises were added to the sides of the structure. All this will become a reliable basis for climbing plants, which after a while will provide beautiful and cool shade.

Pergola canopy

Installing a large canopy can be made from a simple bench into a swing. This functionality will be appreciated by both adults and children.