what a steam room is . The steam room is a small room in size, but bath lovers appreciate the versatility of the steam room, noting the healing power of steam, an oak broom, and communication with friends. To obtain pleasure, it is necessary to create comfort by correctly arranging individual parts in accordance with their purpose.

Steam room project in a bathhouse

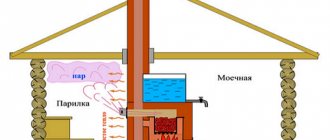

Externally, the steam room looks like a simple small room, without windows, but with a door. The internal contents of the steam room include some unique structures: a stove-heater, wooden shelves and ventilation holes.

The bathhouse, like the steam room itself, is built from natural wood. Aspen, cedar and linden are considered the most acceptable types of wood due to their low thermal conductivity.

Installation of the ceiling and roof frame

8 ceiling beams were mounted on the top frame of the walls, and saw cuts were made at the ends of the beams to accommodate the angle of the rafters. Connections from 3 beams were installed.

8 ceiling beams are mounted on the top frame of the walls

Three beam connections

The rafters were assembled using classical technology. First, the outer rafters were exposed, pinching the ridge. Then two rafters were fixed in the center. The remaining rafters were nailed through the ridge, first on one side of the roof, then on the other.

Please note that cuts were made on the outer rafters for cantilever beams to extend the roof.

Installation of rafters for a frame bath

Vertical gable posts were installed, the dimensions were determined locally. The opening for the attic hatch is formed with beams.

Cantilever beams are embedded in the recesses on the outer rafters. Frontal boards were nailed to them, and additional sheathing was attached on top.

Cantilever beams form the roof extension

Finished roof truss system

Selecting steam room parameters in a bathhouse

Before starting to design a steam room, it is important to determine not only its parameters, but also the size of the dressing room. To do this you need to adhere to the following rules:

- The area of the steam room depends on the number of users, with an average of about 0.7 square meters per person. m. For small steam rooms with seating, the area per person is reduced accordingly;

- The ceiling height of the steam room should be calculated at 20 cm greater than the height of the tallest user. The most suitable height, according to experts, is 2.20-2.40 m;

- too high a height in a steam room for a bath will require more heating power, since the heat from the stones always rushes upward;

- Depending on the type (sedentary or lying down) and the number of shelves, the width of the steam room depends. When calculating the minimum width, the height of the tallest user plus an additional 20 cm is taken into account;

- It is necessary to leave some gap in the form of an air gap from the stove to the walls and shelves in order to ensure the safety of its operation.

In addition, it is necessary to take into account the thickness of the finishing and thermal insulation layers.

We insulate the walls

With frame wall construction technology, you will need additional insulation for the walls. The very principle of operation of the room should resemble a thermos. This will help save costs on fuel for the furnace, as well as time to warm up the room and retain heat in it.

The beginning of work is marked by cutting an opening for the stove in the wall. Afterwards the walls are covered with film. Wooden blocks are installed on top of the film. Between them you need to put insulation that is resistant to fire.

Steam room design ideas

In fact, almost all steam rooms look the same. All of them are made from natural wooden materials, perform the same functions and have similar internal contents.

The main difference between steam rooms consists of different positions of shelves, their configurations, types of lighting, parameters, design and design of the heater stove. Ideas for designing a steam room in a bathhouse are presented in the photo.

Only a steam room in a traditional log house can boast the most plausible design. This is a classic version of a Russian bathhouse, made of logs, without decoration, with rough benches and a brick stove.

A wooden steam room with plank walls and sun loungers made of linden or cedar, with a brick or metal heater, has a more modern look. Stylish lighting, birch brooms, wooden buckets and ladles are used as decoration.

At your own discretion, you can arrange and fill the steam room with whatever you want. The decor of the log panel will give the steam room a modern, Art Nouveau style. LED lighting and original lamps will make the design more exotic.

Features of the steam room construction

When arranging a steam room with your own hands, you need to adhere to a number of rules.

Selection of oven

The main parameters on which the operation of the furnace will depend are: the number of stones and the duration of their heating, the power consumption of the furnace, the grate material, the heat resistance of the body and the design of the unit. To provide heat, in addition to the steam room, the adjacent rooms with their total area of 24 square meters require a power of 25 kW. Building a stove with your own hands will provide an opportunity to save costs on the overall construction of a bathhouse.

Floor finishing

As a material for flooring, the best solution is to use natural stone or porcelain tiles. For safe movement, plank flooring is laid. There is absolutely no need to insulate the floor. Moreover, one of the requirements for the arrangement of the floor is the creation of a hole for water outlet. Wood as a material for flooring is not a good option, since high humidity will lead to its deformation and rapid failure.

Ceiling finishing

For a ceiling, a height of about 2200 cm is sufficient; this is explained by human physiology and the physical properties of steam. With ceiling sizes that exceed this value, steam will escape upward and the effect of its action will simply be lost. Reducing the height will lead to discomfort during bath procedures, since there is a risk of head injury and difficulties arise when working with a broom.

Doors and windows

Installing windows is not considered a requirement. Glass or wood will be the most optimal material option for constructing doors.

- A glass door is practical.

- A wooden door is a tradition.

Determining the correct location of the furnace and choosing a steam source

Important factors when choosing a stove are the size of the steam room, the energy source and the method of generating steam.

A heater is a traditional solution when choosing a stove for a sauna. Stones are placed inside this oven. The traditional fuel is wood, but gas or electricity can be used. Furnaces can be of several types.

- On wood. The installation of this stove in the bathhouse can provide a unique atmosphere. Even the fact that this stove will need to be periodically cleaned to remove soot from the stones will not overshadow the pleasure of taking a bath procedure. In order to reduce the appearance of soot, it is necessary to use aspen firewood as fuel. To maintain a stable temperature, you need to constantly monitor the combustion process.

- Gas. The use of a gas oven is characterized by good maintenance of the required temperature in the steam room, excellent heating speed and ease of operation. A significant disadvantage of this device is the size of the furnace and its large demand for gas. Using a furnace of this type is not advisable when there is no connection to the central gas line.

- Electric. The heater, which runs on electricity, is quite easy to use. This electrical appliance makes it possible to quickly achieve the required temperature, has sufficient power and is compact. Its arrangement does not require the organization of a chimney. The electric heater is safe for humans and the environment; due to the use of automation, its maintenance is simplified as much as possible, and its design features prevent the possibility of injury. The main disadvantage of this device is its high electricity consumption.

Types of heaters

The heater can be closed or open. If several people plan to visit the sauna at the same time, then the best choice is an open type of heater. The firebox (the place where the fuel burns) is not equipped with fire-resistant masonry. It is the place where stones are placed. This stove device allows the stones to heat up and warm up all the rooms of the bathhouse. When exposed to water, heaters with this device quickly lose temperature. This design is used in electric furnaces.

A closed stove is considered a traditional option for arranging a bathhouse. In this case, a large number of stones are placed in a special place in the furnace. In this case, steam is released through a special door; its level is opposite the stones in the first row. During fuel combustion, this door must be closed. To heat the steam room, open it in advance.

Selecting materials for finishing a steam room in a bathhouse

When building the best steam room for a bath, owners always hope for long-term operation. To meet such expectations, it is necessary to build a bathhouse from quality materials.

For wall cladding, it is recommended to use natural wood lumber with low thermal conductivity and high moisture resistance. These species include cedar, linden, aspen, black alder and ash.

As a thermal insulation material, it is recommended to give preference to foiled mineral wool, which has better moisture-resistant properties. Foil materials are also suitable for waterproofing: aluminum foil, penoizol and glassine.

To remove air without contact with water, install a vapor barrier made of polypropylene film or membrane variolation made of kraft paper. Plastic ventilation pipes are the best option for air supply and circulation.

Principles of vapor barrier

It is very important to take care of high-quality vapor barrier. This is due to the fact that hot air is much lighter than cold air, therefore it collects closer to the ceiling.

Thus, it is highly undesirable for the ceiling to have holes, cracks or gaps through which steam could leak out.

To carry out proper vapor barrier you will need to do the following:

- Attach foil, a special membrane or penoizol to the floor beams.

- The slats are screwed onto the waterproofing layer at a distance of about 70 cm from each other. To increase the service life of the slats, they must be well treated with antiseptics.

- The lining is attached to the slats themselves.

- A hole for the chimney is cut in a certain place on the ceiling.

- The attic is insulated.

- An additional layer of protective membrane must be placed on the insulation layer.

- Floor boards are attached on top of the membrane in the attic.

Installation of a steam room in a bathhouse

The process of constructing a steam room in a bathhouse consists of several main stages:

- development of a design for a bathhouse and all its components: dressing room, steam room, internal contents of the steam room (what kind of shelves, heater, lighting, accessories and even stones are needed for the steam room in the bathhouse);

- calculation of the amount of materials needed;

- design and calculation of ventilation ducts;

- laying a brick stove on a concrete base;

- finishing of walls and ceilings with waterproofing and heat-insulating materials;

- covering the steam room with natural wooden materials (lining, boards)

- placement of shelves (beds), installation of lighting and lighting;

- filling with decorative elements and special devices.

As you can see, making a steam room in a bathhouse is not difficult; it is important to be patient, as well as certain knowledge and skills.

Installing the stove

As for the stove, its choice and place for its installation - all this should be thought out at the stage of creating the project. The place for the firebox can be arranged both inside the steam room and outside it.

The stove must be installed in a specially designated place, which is processed and prepared in advance. The stove itself must be lined with bricks. A metal passage for the chimney is mounted on the ceiling.

A damper is installed on top of the stove along with a pipe, tanks are connected to them and discharged through the chimney. Insulation must be carried out with materials that are resistant to fire.

Photo of a beautiful steam room in a bathhouse

Ventilation

The ventilation system is a very important point. Its absence or incorrect installation entails the following consequences:

- the appearance of various types of bacteria and fungi;

- rapid consumption of energy and heat, wasteful use of fuel;

- There is no oxygen supply to a closed, unventilated room; as a result of being in it, you will eventually begin to breathe carbon dioxide, which can lead to loss of consciousness.

Natural ventilation can be done. To do this, there must be a small window and a vent in the oven. Air will enter through the first and exit through the second. A mechanical system of two fans works in the same way. One of them brings in fresh air, and the other removes carbon dioxide.

Your well-being depends on the correct design of the ventilation system.

A proper ventilation system is:

- arrangement of air in layers: below it is colder, rising to the ceiling, the temperature rises;

- the general temperature does not go astray;

- CO2 and other impurities are replaced by oxygen.

To achieve this effect, two rules must be followed.

- The hole where oxygen will enter should be at the very bottom. Ideally, near the stove. This will ensure a flow of cold air to the floor. Near the stove it will mix with the hot one, which means the temperature balance will not be disturbed.

- The second rule concerns the exhaust vent. It needs to be done exactly the opposite: away from the stove and higher.

Install dampers in ventilation openings to regulate air circulation.