Floor waterproofing with liquid glass is a type of penetrating insulation. It is obtained industrially from an aqueous solution of sodium silicate. Fine quartz sand is mixed with soda and fired in a kiln.

This is practically the only material that can be used to cover the base at high humidity; it is used in residential and industrial premises, swimming pools, baths, and saunas. Suitable for protecting wooden surfaces from moisture and protecting the material from fungal infections.

Using ZhS

The use of liquid glass in construction is due to its qualitative properties. It increases water resistance, which is especially important when constructing foundations for hydrological structures (fountain, pool, etc.). It also increases the heat-resistant qualities of bases for stoves, fireplaces and other heating devices.

Coating insulation of the pool bowl with glue Source dm-art-design.ru

The more liquid glass you add to concrete, the faster it will set, for example:

- if the material is 2%, then you can walk on the solution after a day;

- at 10% – after 6 hours.

Excellent waterproofing and heat-resistant mixtures are prepared from this glue. The primer is made from cement, water and liquid glass. Excellent insulation is obtained from glue and sand. The use of liquid glass has shown excellent results on the walls of wells, wet tunnels and basements.

The refractory mixture is made from sand and cement with the addition of office glue. The walls of the fireplace and stove are treated with it using a wide brush. In addition, you can use liquid glass for wood in the form of an antiseptic. To do this, the glue should be diluted with water.

Wood treated with glue Source www.cedar-stuff.com

Liquid glass is applied to a vertical surface in an even layer using a regular paint brush; on a horizontal surface it is easier to pour it and spread it with a squeegee or spatula. If the coating with liquid glass is supposed to be double-coated, then the first layer must dry completely.

Liquid glass - what is it?

This term refers to a water-soluble mixture of potassium or sodium silicates. Lithium silicates are used for electrode coating. The material has a viscous structure and consists of tiny crystals. When they hit the surface, they increase in size and fill microscopic cracks and pores. This creates a water-repellent and heat-resistant layer.

Penetrating waterproofing: applying a solution with LC Source obustroeno.com

The formulas of liquid glass or silicate glue are as follows: K2O(SiO2)n or Na2O(SiO2)n.

This glue was first obtained by the German mineralogist and chemist Jan Nepomuk von Fuchs in 1818 by the action of alkali on silicic acid. In addition to waterproof concrete and cement, potassium or sodium liquid glass is used for:

- preparing fireproof paint;

- gluing linoleum and PVC boards;

- self-leveling floors;

- antipyrrhenes for wood;

- impregnation of fabrics;

- securing weak soil;

- cellulose gluing.

If you add liquid glass to a cement solution, then after hardening you will get a very durable monolith.

Safety precautions during operation

It is recommended to wear rubber gloves and boots when applying glass waterproofing coating.

When diluting liquid glass, a strong alkaline reaction occurs, so you need to prepare a large container with clean water and vinegar.

A weak vinegar solution will neutralize the alkali if it comes into contact with the skin.

When pouring a glass coating, you need to protect the room from drafts. To do this, do not turn on the air conditioner and heating devices until the base is completely dry.

Proportions and mixing

Depending on the purpose of use, the proportions of the various components of the solution are chosen. Ready-made mixtures intended for a particular task are more expensive, so solutions prepared directly at a construction site are often used.

Stationery glue on the floor Source fundamentplus.com

Composition for coloring

The effect of silicates on coloring pigments significantly limits the number of shades. Potassium silicate is used to prepare coloring compositions - it gives a more uniform color, unlike sodium. Such dyes are produced in ready-made versions; you only need to combine 2 components.

See also: Projects of houses with second light

Primer

To get a good primer, glue and cement should be taken in equal quantities. This coating will significantly strengthen the concrete foundation. Lighter solutions are made for tiles.

Impregnation

To increase the service life of elements and structures, an aqueous adhesive solution is used in a ratio of 1/5. Impregnate with a spray gun or brush. Small items can be completely immersed in the mixture.

Waterproofing

To protect concrete from water, prepare a solution of sand, cement and glue in equal parts. Water is added until the mass becomes homogeneous and plastic.

Fire protection

Masonry mortar with heat-resistant properties consists of cement and sand in a ratio of 1/3. Water is added until a plastic consistency is obtained, silicate glue is added last and makes up approximately 20% of the mass.

Preparing silicate solution - tools and consumables

To prepare the composition you will need the following materials and tools:

- cement;

- river sand;

- silicate powder;

- water;

- a bucket for measuring parts of components;

- drill with auger attachment;

- brush, sponge, roller or spray gun;

- mixing container.

It is advisable to sift the sand to prevent the ingress of clay impurities that will reduce the quality of the silicate mixture. The water for mixing must be clean, free of debris and silty impurities.

Video description

In the video, testing wood treated with liquid glass for combustibility:

Antiseptic

To prevent rotting and damage to surfaces by fungus and mold, structures are treated with liquid glass diluted with water in a ratio of 1/1. Use glue for processing concrete and wood.

Repair composition

Liquid glass, cement and sand are taken in a ratio of 1/1/3. Water is added until a sufficiently thick consistency is obtained so that the solution does not flow out of the cracks when they are eliminated. The mixture is also used when sealing joints and pouring screeds.

Mixing the solution

To properly mix a solution using liquid glass, you must follow the recommendations for certain mixtures for treating and repairing surfaces. Dry ingredients and glue with water are mixed separately.

Screed with ZhS Source i9.photo.2gis.com

See also: Specialize in the design and construction of small forms

Dry components are added in parts to the solution, and not vice versa. For greater plasticity, the volume of water is increased. The mixture is applied to the surface, taking into account finishing technologies.

Application of liquid glass

When working with potassium or sodium liquid glass, you should use protective equipment - a special suit and mask. If the mixture gets into your eyes or skin, rinse with plenty of water. Since the solution sets quickly enough - within 30 minutes, you need to calculate the one-time volume of the batch. After half an hour, you can apply the next layer.

Basement waterproofing

The basement is an important structure, so protecting it from moisture is the main condition for a favorable atmosphere in the house and the safety of food. Most often in the basement there is poor insulation of joints and the presence of cracks.

Basement insulation diagram Source moydomik.net

To get rid of them:

- first clean the seams and cracks from various inclusions and dust;

- then prepare a solution of silicate glue and cement in a ratio of 1/20, add water until a plastic consistency is obtained;

- then apply the mixture to the seams or cracks and level them with the same solution;

- After this, coat with water using a brush.

After a day, it is better to apply a layer of glue to the repair site.

Treatment of a concrete well, swimming pool

First, the concrete is cleaned with a brush to remove dirt and dust. After this, apply one layer of impregnation with a roller or brush. After half an hour, apply the second layer. Liquid glass should lie evenly, without gaps. Then prepare a solution from a cement mixture and silicate glue in a ratio of 9/1 and apply it with a spatula in 20 minutes, taking into account the low viability of the solution.

Technology

Surface preparation

Such work often comes down to only cleaning from dirt, removing various fasteners (nails, screws, etc.) and leveling. By the way, the latter is done if necessary, depending on the method of external finishing.

But all this is not entirely true, since more events should be held. It is necessary to take into account that after all work is completed, the wall (floor, ceiling) will be “closed” from free access. Therefore, care must be taken to maximize the service life of the base material. How it's done?

- After cleaning, the surface must be washed so that all defects become visible. In particular, loose seams, cracks and the like. Their sealing is necessary in order to reduce heat loss in the room and additionally protect it from the penetration of liquids. In addition, such careful preparation of the base cleanses the pores of its material from dirt, which ensures deeper penetration of the liquid crystal into its structure.

- To prevent the occurrence of dampness and its “companions” (mold and mildew), it is advisable to impregnate the surface with an antiseptic composition. If we are talking about finishing structural elements made of wood, then be sure to use fire retardants (against fire) - read more about this here.

Further - depending on the method of further cladding. Activities include:

- applying putty. This is done in order to level the base as much as possible (for example, for painting);

- padding. To ensure high-quality “adhesion” between the surface being treated and the material being glued (for example, foam boards for insulation).

Waterproofing of RC can be done in different ways. Let's look briefly at each type.

Coating

Can be used as a main or additional (if necessary, for rolled products). It is not always possible to use bitumen-based products (including mastic) for this type of work. Therefore, the base is pre-treated with a solution of “liquid” glass. It is applied in a thin layer, and the crystals fill all the pores of the material, reliably sealing them. After this, pasting with roll products is carried out.

Depending on the specifics of the structure, sometimes you can limit yourself to one coating. No complications and minimal time. For better surface protection, layers are applied twice; the second - after the first has dried.

If the base is too smooth, for example, a reinforced concrete slab, then it is “roughened” with a metal brush. This will ensure better penetration of liquid crystals into the material.

General recommendations for treating concrete bases with liquid glass

The work of processing the concrete base is done quickly - the ready-made liquid silicate adhesive can simply be mixed using a construction mixer. Work should be carried out at temperatures above plus 5 degrees. After collecting the glue, the container is tightly closed. And :

- there is no need to treat external surfaces if frost is expected;

- if there is ice or frost on the base, no work is carried out;

- When processing horizontal areas, puddles are unacceptable.

Any surface must be properly prepared - silicate glue is applied only to dry and clean surfaces. The top loose layer (ironization and cement laitance) is removed using various tools and units. For large areas - this is a grinding machine, sandblasting and shot blasting machine. For hard-to-reach places and in junction areas - hand tools. The resulting sludge and debris are cleaned out with stiff brushes and a construction vacuum cleaner.

Cleaning up garbage with a construction vacuum cleaner Source kwitka.com.ua

Floor waterproofing

Waterproofing with this material allows you to obtain a surface that is impermeable to water and air.

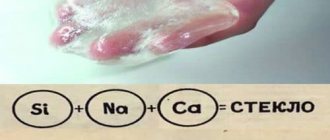

Sequence of surface preparation work:

- We prepare the surface, remove all loose building materials, paint, rust, oil stains and other contaminants from it.

- We sand the surface with a stiff wire brush or sandpaper.

- Remove dust using a powerful vacuum cleaner.

We take into account that it is problematic to apply plaster or putty on a glass floor, since they will not adhere to the surface.

Apply the diluted liquid glass in several layers.

The total thickness should be 3 mm on a concrete base, up to 6 mm on a wooden floor.

Advantages and disadvantages

Liquid glass has its advantages and disadvantages. The first include:

- low cost;

- low consumption of glue in solutions;

- resistance to precipitation;

- ease of use;

- good adhesion (penetrates 2-3 mm into concrete);

- durability of concrete and protective film.

Along with this, silicate adhesive prevents the accumulation of static electricity and is resistant to acids.

Protective film on wood countertops Source woodspil.ru

Along with the advantages, the material also has disadvantages:

- The protective film is not strong enough and is destroyed by mechanical stress.

- Not applicable on brick.

- When waterproofing the foundations of buildings and structures, rapid crystallization of the composition with the addition of LC occurs.

If the proportions of components in solutions are not observed, it is impossible to obtain the expected result.

Ensuring safety precautions

The glue is non-toxic, non-flammable and non-explosive. The prepared mixtures are stored in a dry, cool place at a positive temperature of 5 to 40 degrees.

Safety precautions and precautions Source beton-house.com

Silicate glass is frost-resistant and can withstand temperatures down to minus 34 degrees. The material can withstand 5 freeze/thaw cycles without losing its consumer properties. Should not be placed near heating devices or operating equipment. Residues must be disposed of correctly - do not pour into water bodies, soil or sewers.

Rules for working with material

To ensure a durable coating, you must follow the following rules:

- the temperature range should be from -5 to +30 degrees;

- You need to prepare the mixture in small portions, as it hardens quickly;

- When applied to a metal surface, it must be degreased.

Do not add material undiluted with water to ready-made plaster or cement mortar. We add it in the form of an aqueous solution in compliance with the proportions.

The reasons why the screed will be weak are different:

- Failure to maintain the proportions of water and cement.

- Old cement (with lumps).

- Increased clay content in sand.

- Improper preparation and care after installation when rapid dehydration conditions occur.

But if this happens, then something needs to be done about it - because with further finishing, difficulties are possible.

It is also impossible to leave it unchanged. Dust constantly forms on such a floor. The weak layer is easily destroyed by feet.

First way. Strengthening with primer.

The first thing most people come to is to strengthen it with a primer. The option is real, affordable and on everyone’s lips. But it rarely gives results:

A short comment on the video.

Judging by the nail test, the screed is quite suitable for tiling indoors. There are examples of a more deplorable state of the foundation, which they tried to strengthen with a primer:

For what reason did the tile bounce off the screed?

They tried to strengthen the loose screed with a primer. But primer, primer is different. Judging by the color and the resulting film, a concentrate primer was used in shock proportions. Or primed several times, allowing each layer to dry completely (as written on the canister). This gave a film on the surface. A tile with glue was attached to it. But under the film the same weak layer remained. The tile came off along it.

Where to order JS?

Searching and choosing a store or supplier of liquid glass directly depends on the required volumes for your goals and objectives.

In small quantities it can be found in construction markets, hypermarkets or on websites.

But if you need to purchase sodium liquid glass in large volumes of 1 ton or more according to individual characteristics, you must contact federal manufacturers, for example, the Promsteklocenter company. According to the information posted by this manufacturer, it produces and supplies silicate products throughout Russia and the CIS in any container and by any transport, and also owns its own laboratory, which guarantees high quality of the product.