Draft is a flow of air and flue gases coming out under the influence of aerodynamic forces using an exhaust duct. In plain language, normal chimney draft is a system where smoke and gaseous products obtained during the combustion process move through the chimney and exit. Backdraft is the flow of smoke into a living space. The chimney and exhaust ducts perform an important task by throwing out air filled with combustion products that is harmful to human life. But what to do if there is no traction? Let's understand the reasons.

Signs of lack of sufficient draft in the pipe:

- Smoke entering the room;

- Smoke in exhaust ducts;

- Soot deposits on the door.

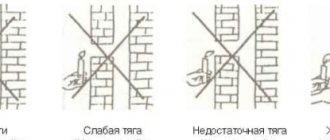

If you doubt that the chimney will perform its intended functions 100 percent, there are several simple ways to check how strong the chimney draft is.

- You need to insert a lit candle into the stove, analyzing the direction of the flame. The flame leans back, which means there is sufficient draft; the flame is motionless and ripples – the draft in the chimney is insufficient.

- You need to take a light ribbon, a piece of toilet paper, and bring it to the beginning of the exhaust duct of the firebox. If the sample pulls upward, then there is no malfunction; if it hangs under the influence of gravity, the air does not circulate.

- You need to place the mirror near the firebox and wait. Moisture appearing on the surface indicates insufficient smoke removal.

- You need to analyze the color of the fire: yellowish-golden color is correct. The fire is a deep orange color, red, which means there is not enough air movement.

- To determine the degree of adequacy of draft, you can analyze the behavior of the smoke; in this case, moderation is important. It is enough to bring a lit cigarette to the base of the chimney and burn a small piece of newspaper.

Top reasons for lack of traction

It is necessary to determine the time frame for the occurrence of the malfunction. Separately, it is worth considering cases when the chimney is new and during a test run the fact of reverse draft is revealed. Let us consider the reasons separately and in detail.

Reason 1. Incorrect chimney.

Proper chimney design is important for good air movement. If there is no draft when checking a new heating structure, then the reason is one or a combination of errors:

- The pipe diameter is too small and does not correspond to the installed capacity of the heating system being served.

- The chimney design has 90 degree turns. The maximum allowable rotation angle is 45 degrees. For ideal operation, the entire chimney must be extended along a strict vertical axis. However, such a design is not always possible; then tees and reducers are used. For a 90 degree rotation angle in the chimney, it is necessary to add 1 meter of pipe length. For a rotation angle of 45 degrees you need to add 0.5 meters.

- The presence of horizontal sections of the chimney. The total length of horizontal sections should not exceed 1 meter.

- Irregular pipe shape. The pipe must have a round cross-section. In the corners of the square pipe, a turbulence of the air flow occurs, which clogs the chimney. Square sections have chimneys made of brick; for their normal functioning, stainless steel pipes must be installed inside. Stainless steel pipes are easy to install, airtight, and their smooth surface prevents the accumulation of soot.

- The blower is not long enough, which does not provide the required oxygen flow.

- The chimney consists of pipes of different diameters; in places where there is a difference in size, favorable conditions are created for the accumulation of soot and soot.

- Insufficient tightness of pipe joints.

- No cap over the chimney. The cap protects against exposure to precipitation and objects that can clog the chimney (snow, dead birds).

- Incorrect pipe placement. The pipe should rise above the flat roof by at least 0.5 meters. The distance between the ridge and the pipe should be 1 meter. The total length of the sleeves must be at least 5 meters.

- Insufficient chimney insulation. The part of the pipe located outside the heated room must undergo insulation. Insulation will prevent gases from settling in the form of condensation on the inner surface of the pipe.

Reason 2. Ventilation

For proper operation of the heating system, proper ventilation must be established in rooms with approved combustion equipment. Often because of this there is no draft in the chimney. Reasons for lack of sufficient traction:

- Constantly open windows in the furnace room. Especially when the windows are located above the firebox.

- A strong draft, aerodynamic forces can change the direction of air movement.

- Insufficient fresh air required for combustion.

Reason 3. Exposure to natural factors.

The reasons for the lack of chimney draft can be:

- Rain, snow, hail, creating a pressure difference. Exposure to high street pressure leads to combustion products settling in the chimney, reducing the useful volume of the chimney.

- The crown of a tree obstructs free access to air masses.

- A tall building nearby reflects the smoke coming out of the chimney.

- Using raw wood as a raw material.

- The canopy is too low above the pipe.

External inspection and repair

To understand why the stove smokes, you need to carefully examine the entire structure from the chimney to the ash pan.

In this case, you need to pay attention to the integrity of the structure, the absence of cracks, loose seams, traces of soot and smoke. Peeled pieces of plaster should be removed, carefully check the condition of the seams between the bricks in a cleaned area

All detected defects must be corrected.

What to do if there is a lot of damage? The best option may be to completely replace the masonry in the damaged area. When used in the upper part of a metal pipe, it can be fixed by arranging temporary fastenings to the roof and attic parts. Then you can begin dismantling the masonry. The brick must be cleaned of old mortar, soot and carbon deposits, and sorted. Then make a new laying.

If there are minor damages, you can remove defective bricks, old mortar, and lay new ones. In this case, it is necessary to ensure that the seams are filled as completely as possible. After repairs, the walls need to be plastered with clay mortar; after drying, it is advisable to whitewash them. In addition to a neat appearance, defects that may occur during further use will be more noticeable on a light surface. After completing the repair work, it is necessary to clean the pipes and chimneys.

Ways to eliminate backdraft

Having determined the reasons for the discrepancy with the air duct, we will try to find a solution. If there is no draft in the chimney due to imperfect chimney design, you should:

- Increase the diameter of the chimney pipe to the size of the firebox outlet. Aligning the diameters will increase the intensity of air movement.

- Extend the pipe so that it rises 0.5 meters above the roof, if there are tall trees nearby, high-rise buildings by 1.5 m.

- Remove 90-degree angles from the chimney and replace horizontal sections with inclined ones.

After eliminating all design errors, check the traction again. If you are unhappy with the result, then it may be that the fuel unit itself is faulty. Check the boiler, stove, fireplace.

No traction in the stove in the bathhouse: what actions to take

It happens that the stove in the bathhouse smokes and burns poorly due to poor draft. You can make a device for cleaning pipes from soot with your own hands. You will need:

- rope;

- plastic bottle;

- load (sledgehammer).

What to do:

- Attach a sledgehammer (a metal part with a hole) to the end of the rope.

- In the middle part of the bottle, make longitudinal cuts along the entire perimeter at a distance of 1.5-2 cm from each other. When the device moves up and down the pipe, they will scrape soot from the walls.

- Make holes in the bottom of the bottle and in the tire.

- Place the container on a rope (over a sledgehammer) and screw on the lid.

- Tie a knot in the rope over the tire hole.

- Clean the pipe.

Some of the soot will fall into the firebox, and some will fall inside the bottle. The draft will become normal, the stove will stop smoking.

How to return normal cravings

If there was draft in the chimney and until a certain moment you did not know that smoke could remain indoors, then you should try to return normal draft using options.

- Chimney cleaning. There are two options for the operation. The first option is an old one: attach a large rag to a long stick and clean the pipe like a bottle brush. The second version of the operation is progressive: add substances to the fuel that enter into a chemical reaction during the combustion process, removing contaminants outside. The cleaning agent can be sodium chloride (when using firewood) or special compounds sold in stores. The chimney must be cleaned every six months.

- Elimination of external factors. If it is not a matter of design, accumulation of soot, or soot, then it is a matter of external factors that impede the free movement of air masses. The cause may be trees, tall buildings, or strong winds inherent in this terrain. When it is impossible to eliminate the source of the causes, special devices should be used: stabilizers, deflectors, rotary turbines.

The role of the damper in the operation of the heating system

Damper to reduce the intensity of combustion and draft

A damper, or damper, eliminates the possibility of developing reverse draft and increases the fire safety of the room. It is installed using 2 methods:

- into the chimney pipe;

- on the oven door.

The damper serves as a kind of regulator. When the gate is closed, the cross-sectional area of the pipe decreases along with the draft and vice versa.

Stabilizing devices

The reason for the lack of draft in a chimney located in a bathhouse in a residential building may be overheating of the outlet pipe, leading to a temperature difference and sedimentation of combustion products on the inner walls of the pipe in the form of condensate.

The stabilizing device consists of a regulator equipped with a temperature sensor and a fuse damper. When the temperature rises, the sensor gives a command to open the damper, and cold air flows through the hole, equalizing temperatures and pressures.

How to clean the stove and chimney with your own hands

The pipe can be cleaned without climbing a ladder to the roof. There are special chemicals available for removing soot:

- Chimney Sweep log. This is a small briquette consisting of coal wax, phosphorus oxide, and ammonium sulfate. It is placed in the firebox and set on fire, it burns for 1.5 hours, clearing the walls of the chimney channel of soot.

- “Komichek” - granules for cleaning metal sandwich pipes and brick chimneys, packaged in small bags. Contains copper chloride and activated carbon. The bag is thrown into the oven on firewood, the door is closed tightly. When burned, chemicals are released that dissolve the soot.

- PKH is an anti-carbon chemical composition.

Effective cleaning of soot from a pipe can be done using the old fashioned methods:

- dry potato peelings. Place the dry peel into a well-heated firebox and set it on fire. The starch that is formed during combustion will dissolve soot build-up on the pipe walls. For preventative cleaning, you will need a full bucket of cleaning;

- mix 7 parts of saltpeter, 2 parts of coal, 5 parts of vitriol, burn a small amount (20 g) in the stove with the door tightly closed. Carry out the procedure 1-2 times a month;

- several times during the heating season, burn an armful of aspen firewood in the stove;

- Throw mothballs into the hot firebox. The product releases vapors that destroy the soot layer;

- Burn 2 liters of walnut shells in the oven;

- Throw a couple of tablespoons of salt onto burning wood; it softens the layer of soot, which lags behind the walls and falls into the firebox in the form of flakes.

You need to be careful when cleaning pipes with mothballs and walnut shells. Naphthalene is explosive and can ignite soot in the pipe. Walnut shells have a high combustion temperature, which can cause the pipe to become deformed and crack.

If the draft is good and the stove does not smoke, the chimney still needs to be cleaned. Soot deposited on the walls can ignite at any time and cause a fire. The safety of the home, garage, bathhouse and the operation of the heating device depend on the cleanliness of the pipe.

Strength check

Before you try to fight bad traction, make sure that your traction really leaves something to be desired.

You can check the traction using special devices or yourself. Simple ways to fix traction:

- Light a piece of paper and let it burn for a while. When you bring it to the stove or fireplace, extinguish the paper and observe the direction of the smoke. If it is directed towards the pipe - good thrust, deviates in the opposite direction - reverse thrust, if it remains “straightforward” - there is no thrust. Similar manipulations can be done with thin tissue or toilet paper without setting it on fire.

- If there are smokers in the house, then follow the direction of the cigarette smoke or the flame of a match or lighter near the fireplace or stove. Draw conclusions similar to the first point.

- The flame of an ordinary candle can also help in determining the draft in the home.

- A pocket mirror brought to the firebox and covered with condensation may indicate problems with removing smoke from the stove.

- The presence of too much draft, which carries away useful heat from the room, is indicated by an audible hum in the stove - a loud hum.

- The color of the fire in the firebox can be an indicator of different drafts. A golden hue means good draft, white flame means excessive draft, red color and black smoke means poor draft, high probability of reverse draft.

A regular lighter can help test traction

An anemometer is a device familiar to many people of the Soviet period. Using this device it was possible to measure the draft of the chimney. Readings within 10–20 Pa were considered normal. The disadvantages of the device are its low accuracy when the wind force is less than one meter per second.

This simple device will help protect your life in a stove-heated home.

Modern industry offers a sufficient number of devices for measuring draft; there are devices that record draft at the inlet and outlet of the chimney.

Stabilizer installation

The chimney draft stabilizer involves the installation of an additional structure in which a gas boiler draft sensor is built-in.

To install the system, a so-called umbrella is installed on the chimney pipe. Between the open part of the hood and the smoke outlet pipe there is free space through which air flows freely pass. With its help, the stability of the air flow is monitored to determine the desired level of traction force in the chimney pipe. If necessary, a special gas boiler draft sensor is installed in the cap on the chimney pipe. He monitors the temperature inside the chimney. The sensor is triggered when the temperature of the gases rising through the pipe decreases.