On the Russian market of sauna stoves, Vulcan stoves have a good reputation. They are produced in Odintsovo at the Vulkankomplekt enterprise. There are 7 types of stoves today, plus they are produced in 10 modifications. There are models with an open or closed heater, some with a remote or built-in tank for heating water, and some without it at all. “Vulcan” sauna stoves are produced with different volumes of steam rooms: from 6-8m3 to 20m3. Plus, there are two combustion options: fuel is added in the same room or in an adjacent one, through the wall. Moreover, the remote firebox is protected by an arch. This makes installation easier: the arch does not heat up to critical temperatures, and there is no need to make part of the wall from heat-resistant bricks.

Time-tested sauna stoves Vulcan VU-05 and VU-09

Installing an iron stove: choosing a base

Nobody just puts a metal stove on the bath floor.

And here's why: the thing is heavy, and therefore it would simply begin to sag on the floor over time. And it would do it unevenly. And when the stove is not level, it can crack. Therefore, either a brick foundation is made for it, or even a separate foundation with verified level horizontal lines to prevent destruction of the furnace. To decide whether you need a lightweight or a full-fledged base, you must first calculate the mass of the stove with everything due to it. You will learn how to do this from our article - you don’t want to repeat yourself, but everything is described in detail there.

Power calculation for a bath

To calculate the power of the bath, it is worth taking into account several important factors:

The norm for 1 person is 11 cubic meters. baths, and the furnace power is calculated based on the volume with a coefficient of 1.2; Russian and Finnish baths differ both in humidity and in temperature, which is also very important to take into account when creating an effective calculation.

Calculation example:

As a basic calculation method that does not require a person to have special knowledge, it is worth accepting this:

Background information:

- let the volume of the bath be 5x3x2.5 meters - 37.5 cubic meters;

- to heat a cubic meter of room to a temperature of 30 degrees, you need 25 kcal per hour;

- during operation, 1 square meter of oven area will produce 300 kcal per hour;

Thus it turns out:

- to heat our Russian bathhouse (60 degrees) per hour it will take 37.5 * 50 = 1875 kcal/hour;

- It follows from this that the stove surface area for such a room should not be less than 6.25 sq.m.

This algorithm requires only individual data from the region of the person who wants to install such a stove, because the weather conditions of the region are also taken into account here

New stoves for the Vulcan bathhouse

Since the second half of 2013, new modifications of the popular and proven models Vulcan VU-05 and VU-09 have appeared - Vector VU-05 and Vector VU-09. Their feature is a special convection kit and a mesh on the pipe for stones. For those who prefer dry steam, this is an ideal option.

Since the beginning of 2014, Vulcans have appeared in the premium class. These are the new Etna Premium sauna stoves, which are distinguished by a more sophisticated design. Moreover, the designers worked not only on the body itself, but also on the accessories for the pipe; they also developed a special cast-iron grate and four door options instead of the usual two.

New developments by Vulcan specialists. Etna Premium is distinguished by its non-standard, sophisticated design.

The old models Vulcan VU 02, 05, 07 have been replaced by new modified bathhouse stoves Elbrus 16, 20, 26, which have several modifications and configurations. There is also Elbrus 40, but it is classified as a sauna stove for commercial use - such a stove can heat a room from 25 to 40 m3. The category of “commercial” furnaces is not limited to Elbrus 40.

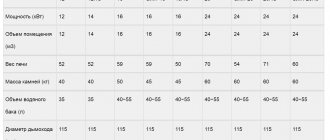

The main technical characteristics are summarized in a table. This will make it easier for you to navigate. Any of these models can be equipped with either a solid cast-iron door or a door with glass.

Main parameters of Vulcan sauna stoves

Prometheus 18 (Panorama modification)

Prometheus has a unique design due to its aesthetic mesh casing (see photo), thanks to which you can lay more stone for the stove.

And this, in turn, allows you to increase heat transfer and create a feeling of comfortable infrared radiation. This stove has design features similar to the Etna model, including a “ribbed” turbo firebox with increased thickness in some places and effective cast-iron grates that can “make” even damp wood burn. In addition, the manufacturer claims that the installed convection kit ensures faster heating of the stone.

- Steam room volume: from 8 to 18 m3

- Depth: 555 mm

- Width: 525 mm

- Height: 810 mm

- Weight of the oven itself: 85 kg

- Weight of stones: up to 200 kg (!)

In addition to the “18”, a more powerful model, the “24”, is produced. Each Prometheus has three modifications, with a cast iron or steel door, as well as with a small flat or large (see photo) panoramic thermoceramic glass.

Disadvantages of Vulcan stoves

We didn't find any negative reviews at all. The general impression is that they are good, well-made metal stoves with all their pros and cons. The disadvantages include several design flaws, which, in principle, are not critical, but reduce the comfort of use.

- The water tank for Vulcan stoves has a small volume (20-40 liters). In addition to the need to drain/add water, there is another nuisance: in a small tank, the water boils before the steam room warms up. If we take models with a hinged tank, a different picture arises - the water takes too long to heat up, which is also not good. According to reviews, the best option is either to take models with remote tanks, or without them at all, and to heat the water, install a separate electric or wood-burning boiler (as conditions allow).

- There is one more inconvenience for models with a built-in tank - the tap for draining hot water is not located very well - if the stove is heated from an adjacent room, then the tap is located too close to the wall, which creates inconvenience.

- Models with remote heat exchangers have a lead diameter of ½ inch, although ¾ would be optimal, but this is already in the area of “process optimization”. The water flows well, but, as often happens, I would like it to be better.

- There is a purely theoretical drawback: the effectiveness of the damper, which switches modes from bath to sauna, is questionable. We did not find any reviews from owners of such “Vulcans” using the function. So how this option works is unknown.

These are all the shortcomings that we found while reading reviews from owners and experienced bathhouse attendants who analyzed the technical data of Vulcan bathhouse stoves (there are also heating stoves, but we didn’t look into them).

This is a photo of the weld around the smoke pipe (left click on it to enlarge)

Now the reviews themselves. We present impressions from the operation of only sauna stoves, not heating ones.

“I had two Vulcans, both for a long time. Each one is more than 10 years old. Moreover, it is still a secret to me what kind of steel they use. Externally, they are ordinary black metal, but they do not burn through. The stove is good, but for a Russian bath you need “dancing with a tambourine” in full: a brick screen, a steam gun and a convector on a pipe.”

My Vulcan is already an old man. And I would be glad to exchange it for a new model (I like the Harmony), but it won’t burn out, it doesn’t seem like it’s even going to. And we only heat it with birch, and harshly: I love high temperatures.

This is a photo of the welded seam of the firebox (to enlarge the size, click on it with the left mouse button)

My Vulcan is already three years old, U16 or 16U, I don’t even remember. My insulation is average. In an hour, the steam room in winter (14 cubic meters) heats up to 90°. I had friends who were extreme sports enthusiasts, and they reached 140°C with oak in 30-40 minutes. I'm happy with this stove, but I'll have to change the pipe to an insulated one, otherwise there's already one leaning against it.

I prefer the Russian steam room, which is not hot, but I decided to test how the damper on the Vulcan works. After steaming, I turned the handle. in a minute the temperature rose from 80 to 90. This despite the fact that the wood was no longer burning, probably due to the stones.

There is still an old Vulcan with a 30 liter tank. Everything is fine except this tank itself. Water boils very quickly and very early. Moreover, the tap is located so low that you need to draw water either by bending over or kneeling. Neither one nor the other makes me happy. And in general, I became convinced that the water tank in the steam room is pure evil. If it boils, it’s on guard, everything is steamed, and it’s kind of sticky. And if you don’t leave it empty, it will burn. I decided for myself: it’s better to install a separate water heater and not toil all the time.

Heating stoves

One of the lines of stoves for the Vesuvius - Elbrus bathhouse looks like this.

Vulcan also has heating stoves. This is the Alpina line, which quickly and effectively warms up the air in the room. Today there are three modifications in this category.

- “Mini” is the smallest, but it can heat rooms with a volume of 50 cubic meters, and it costs very little. Not the most sophisticated design, but if you need an inexpensive stove to heat a garage, greenhouse or any other similar space, then what can be done to suit the appearance, and the efficiency of the stove is very high.

- Alpina 200 is already designed for 200 cubic meters.

- "Alpina 250" - heats 250 cubic meters.

Large Alpines have two doors for loading fuel: the fuel compartment is very large and loading it from one door is inconvenient. A full stash burns and smolders for up to 20-24 hours. Such long-term combustion is ensured by the presence of a gas afterburning chamber, which makes it possible to create a firewood smoldering mode in which complete combustion of the fuel occurs.

The body of heating stoves has a ribbed surface, which increases heat transfer through the walls. In general, the design is quite simple, but effective, but what is needed for heating? Reliability and quality, and no one has yet complained about the quality of Vulcan stoves. In any case, we did not find any negative reviews. And the fact that after an old stove burns out, people come to buy a new one from the same company speaks volumes.

Heating stove "Vulcan" "Alpina-mini" - the most budgetary, but no less reliable option

Design features that you must observe when building a sauna stove

As mentioned above, stoves can be metal or brick, and their designs differ from each other. To understand which one will be more convenient for installation in a particular room, you need to consider both so that you can draw the right conclusion for yourself!

Metal oven

Metal sauna stove with water tank

Cast iron and steel versions of wood-burning sauna stoves have the same design, and their installation can be done in two ways, depending on their design:

- the firebox is located in the dressing room, and the heater is in the steam room;

- The firebox and heater are located in the sauna room.

The first option is preferable, since in the steam room you can accidentally burn yourself on the firebox door. Along with the heater, a water tank is also located in the steam room.

This diagram shows the design of a sauna stove model, in which the firebox goes into the dressing room.

Construction of a wood-burning metal sauna stove

- This oven is equipped with a water dispenser. It is convenient in that you do not need to constantly add liquid to the heater - water or broth, it will gradually flow in the specified amount. It is shown in the diagram as number one.

- At number two in the diagram there is a heater covered with a water dispenser, which, when heated, will give out the gift for a long time. Due to the fact that a metal stove cools down quickly, a closed heater will be a good help for retaining heat.

- A chimney pipe passes through the heater from the firebox. Its location also helps to retain heat near the stones.

- On the other side of the pipe there is the second part of the heater - already open. Water from the dispenser, passing through the closed chamber of the first heater and under the pipe, exits through the open heater in the form of dry steam.

- The deep and voluminous firebox, made of heat-resistant steel, has a chrome finish.

- The firebox contains a cast iron grate, which takes a long time to cool down, which means it also retains the heat from the fuel.

- Under the firebox there is an ash pan chamber with a drawer. Waste from burning wood is collected there, and it must be cleaned after each heating of the stove.

- An exhaust channel emerges from the firebox, having a certain length designed for the thickness of the wall through which it will pass. This model is made to be installed in such a way that the firebox door is in the adjacent room.

- A self-cooling door is installed on the combustion channel. It cools quickly due to the fact that it is located far enough from the combustion chamber.

- From the back of the firebox, through which it exits into the steam room, there is a secondary air supply channel.

- On the front of the case, on the side that will be near the wall on the steam room side, a convector casing is installed, which allows the heated air to escape upward and not into the wall.

- A chimney is placed on the pipe that passes through the heater.

- A water tank is installed on the chimney, operating on the principle of a samovar. The heated pipe inside it will serve as a good heat exchanger. The tank can be filled with water manually, or it can be connected to a water supply.

Convenient water heating tank

- Next, a chimney pipe riser is placed on the tank nozzle, which is passed through the ceiling and roof. When passing through flammable floor materials, the chimney must be insulated with non-combustible materials. The thickness of the insulator should be 7-10 centimeters greater than the thickness of the ceiling and extend towards the attic. The distance between the ceiling and the pipe should be 10-15 centimeters, filled with non-flammable insulator. Sometimes a box is used to lay or fill the insulator.

- Waterproofing must be installed around the head of the pipe on the roof so that moisture cannot penetrate into the attic and damage the wooden elements of its structure.

To install a metal stove, you need to properly prepare the place - it should be a non-combustible area made of brick, concrete or ceramic tiles and a brick wall through which the combustion channel will pass.

Approximate installation diagram of a metal stove in a sauna

The furnace installation diagram looks approximately as shown in the figure. Minor adjustments are possible, for example, if the stove is installed on a brick or concrete podium.

Sauna stove made from a pipe or an old cylinder

The difference between this design and the previous one is that the water tank is located directly above the firebox. For work you will need: a pipe for the stove and tank (wall thickness 1 cm, diameter 50 cm, height 150 cm); pipe for the heater (the wall thickness is the same, and the diameter is 35cm); mortise valve; metal fittings; hinges for doors; steel sheets with a thickness similar to pipes; tools for welding, metal cutting.

Pipe sauna stove

- We divide a pipe of larger diameter in two using a grinder. From one part (length 60 cm) we will mount a water tank, from the second (90 cm) we will construct a heating device for a bathhouse.

- We make markings on a sheet of steel to cut out a circle equal in diameter to the pipe - the furnace body. To do this, it is convenient to use a can of paint or a marker. This circle will serve as the bottom of the structure. We weld it hermetically to the pipe.

- We immediately make the legs of the structure. To do this, we strengthen the bottom of the sauna stove with a metal frame made of profiles. Frame height 10-15 cm.

- After the stove stands firmly on its legs, draw a 25x7 cm rectangle on the body. This piece of metal will be the blower door. We cut it out with a grinder, equip it with hinges, a handle and a latch.

- We make a grate. Its task is to pass air from the ashpit into the combustion zone, hold fuel and not prevent ash and ash from entering the lower chamber of the furnace. Such a grid can be made from pieces of reinforcement or a sheet of metal with holes cut in it. The grate must be secured by welding in the inner part of the pipe at a height of 12-15 cm from the bottom.

- The firebox will be located above the grate. We cut out a door for it measuring 25x30 cm, departing from the level of the grate about 20 cm. We install the door in the same way as the ash door.

- We will construct the heater from rebar. By bending it in different directions, we give the reinforcement rods the shape of a basket, and fasten them together with plastic wire. This is where we will place the stones for the stove. We install the “basket” on the top of the pipe. Here we cut a door of any shape and again equip it with hinges and a latch.

- Next we'll take care of the water tank. The tank body is a pipe, 60 cm long. For this pipe we cut out the bottom, in which we in turn cut a hole and pass the chimney pipe through this hole. We secure the parts by welding. We cut in a tap closer to the bottom of the tank.

- Now we assemble the two parts of the stove together so that the tank is located strictly above the firebox. We make a weld.

- It is convenient to make the lid for the tank double-leaf. We cut out a circle, divide it into two equal parts, one of which is tightly welded to the tank, the other is attached to the first half with loops. To make it more convenient to open the tank, we equip the lid with a bracket handle made of reinforcement.

Thus, from the simplest materials you can quickly and cheaply build a sauna stove with your own hands, and it will not be functionally different from its purchased counterpart! By doing the work efficiently and slowly, you will get a result that will delight you and your guests for many years!

Which sauna stove is better, steel or cast iron?

Electric sauna stoves undoubtedly have several major advantages: they are environmentally friendly, easy to operate, fireproof and, most importantly, do not require the use of additional constructive measures to remove combustion products. Therefore, despite the fact that a wood-burning stove is considered the traditional option for a Russian bath, electrical devices in the steam room are becoming more and more popular.

Although most large manufacturers of sauna units usually have several electric heaters in their range, the most popular electric sauna stoves on the market are manufactured by specialized companies. This is explained by the fact that the design principles of heating devices using the principle of fuel combustion are radically different from the approaches to the design of electrical devices.

Minuses

Dmitry, 40 years old.

Installation of stoves in Russian baths

Vulcan stoves can be installed both in Russian baths and Finnish saunas. This is possible due to the uniqueness of the design, for the development of which both time-tested methods and the most modern ones were used, and the previous experience of domestic and foreign colleagues was taken into account. The result of long and fruitful work is a whole series of Vulcan sauna stoves, among which you can find models that satisfy a wide variety of parameters. For example, someone may find the most convenient Russian stove, the firebox of which is made from the dressing room, and in the steam room itself there is only its back wall. There are also a large number of models, which are loaded directly in the steam room.

We offer a large selection of models in size, designed for heating steam rooms of various sizes, with built-in or remote tanks, or not intended for heating water at all. As you can see, the choice is quite large. Let us repeat: if you do it at the very initial stage, you will get a bathhouse where you can get real pleasure without thinking about any annoying little things.

Selection of stones, fuel

Before you start using the Vulcan stove, you need to choose the right stones for it. The optimal temperature and heat release will depend on this. If the number of stones is insufficient, the sauna will not be able to warm up well. But when the number of stones is excessive, the temperature in the bathhouse will become too high, and this will negatively affect the comfort of staying in the steam room.

Stones for the stove should be chosen carefully

Experts in the field of heat supply believe that 40 kg of stones per 1 m³ of space is optimal. In addition, you need to take stones that do not expand or deform from heat.

It is important that as the temperature rises they do not begin to crumble and crack. Usually round stones are used, which are collected in ponds or quarries

Their size should be determined by the parameters of the furnace itself.

As for the fuel used, hardwood firewood is best. They are prepared and dried in advance. The firewood must be dry, otherwise it will take a long time to burn it.

How to choose and what to pay attention to?

The choice of a wood-burning stove is determined by the needs of the room and the intended use.

First of all, you need to decide on the size and power. These are the main parameters of the device that determine its ability to effectively heat the available volume.

Usually it is assumed that 1 m3 of sauna volume requires 1 kW of power. However, often the parameters of the stove do not correspond to the size of the bath, which is caused by the specific design or the presence of additions that take away thermal energy.

In addition to the basic parameters, you should pay attention to the following points:

- presence of a tank. The ability to simultaneously heat water by some users is considered very rational;

- firebox location. Most models have a lower location, which is determined by the design itself. There are models with an elongated combustion chamber designed for installation in a wall niche. Installations with a conventional firebox are more compact and lightweight, and do not require the creation of an overly strong supporting platform;

- manufacturing material. There are brick, cast iron and steel construction options. The first ones are bulky, require a lot of space, and are stationary. The latter are rare, as they are expensive and quite large. Preference is given to steel furnaces made from special heat-resistant alloys. They are inexpensive and practical;

- heater type. There are open and closed types of heaters. The first is preferred by most users due to the high heating speed, which allows them to quickly heat the bathhouse if necessary. Closed models have a lid over the layer of stones. It limits the loss of thermal energy and heats the room more evenly. At the same time, you will have to start heating the bathhouse several hours in advance (at least 3-4);

- furnace design. There are classic (ordinary), mesh (with a layer of stones around the firebox, laid in a mesh. It covers the entire furnace, surrounding it on all sides with a cocoon of stone), with a steam generator (makes it possible to supply pre-prepared steam) and designs with a water tank;

- installation method. There are stationary and mobile types. For its compactness, most users prefer the second option, although it is less efficient and has low power; The degree of mobility of a wood-burning stove is a very relative indicator. since it is in any case connected to the chimney.

- heated volume. This is a parameter that is directly related to the power of the unit. Usually it is equal to the volume of the steam room, but there may be options when the power is 15-20% greater than the size of the room;

- ash box. This is an element that makes cleaning the ash pan easier. Most modern models are equipped with this device.

IMPORTANT! Choosing a suitable sample should start with power, and only then consider other capabilities of the device.

Disadvantages of Vulcan stoves

We didn't find any negative reviews at all. The general impression is that they are good, well-made metal stoves with all their pros and cons. The disadvantages include several design flaws, which, in principle, are not critical, but reduce the comfort of use.

- The water tank for Vulcan stoves has a small volume (20-40 liters). In addition to the need to drain/add water, there is another nuisance: in a small tank, the water boils before the steam room warms up. If we take models with a hinged tank, a different picture arises - the water takes too long to heat up, which is also not good. According to reviews, the best option is either to take models with remote tanks, or without them at all, and to heat the water, install a separate electric or wood-burning boiler (as conditions allow).

- There is one more inconvenience for models with a built-in tank - the tap for draining hot water is not located very well - if the stove is heated from an adjacent room, then the tap is located too close to the wall, which creates inconvenience.

- Models with remote heat exchangers have a lead diameter of ½ inch, although ¾ would be optimal, but this is already in the area of “process optimization”. The water flows well, but, as often happens, I would like it to be better.

- There is a purely theoretical drawback: the effectiveness of the damper, which switches modes from bath to sauna, is questionable. We did not find any reviews from owners of such “Vulcans” using the function. So how this option works is unknown.

These are all the shortcomings that we found while reading reviews from owners and experienced bathhouse attendants who analyzed the technical data of Vulcan bathhouse stoves (there are also heating stoves, but we didn’t look into them).

This is a photo of the weld around the smoke pipe (left click on it to enlarge)

A little general information about Vulcan brand stoves

The manufacturer, as a proprietary feature, calls a double steel casing, which provides protection from uncomfortable radiation and optimally removes heat from the firebox. Speaking in detail, we are talking about infrared radiant heat transfer.

I can’t judge how innovative this solution is, but there is no doubt that thermal radiation becomes softer, or again, speaking in detail, “longer wavelength in the infrared spectrum.”

But there is something else, for example, fireboxes have built-in dividers that allow you to optimize the combustion process. And the developed ribbed surface in the upper zone of the firebox allows you to increase the area of the heat transfer surface. Phew, I switched to a complex presentation. I'm simplifying.

Thanks to this, the stones heat up more evenly and quickly, and the water evaporates more efficiently. The movement of steam from the furnace into the room is ensured by special control valves. It should be noted that there is a useful design solution - a special hole for cleaning the chimney and furnace labyrinths from soot. It is convenient to operate and no dismantling is necessary.

Models of Vulcan sauna stoves differ in two main indicators: heating volume (m³) and level of comfort. They are all metal (steel). Let's look at the main characteristics.

Classic wood-burning sauna stove

Wood is most often used to heat saunas in the standard version. Furnaces for such premises differ in the type of combustion, and can be continuous or periodic. In the first case, the stove is heated constantly and requires maintaining the fire. In the second option, a single heating is enough, after which the heat remains for several hours.

Wood-burning stoves for saunas or baths, which are classified as continuous, heat the stones throughout the entire process. They are placed so that the heater is located inside the room, and the firebox is on the other side. This ensures free flow of fuel and constant access to the firebox.

In order to prevent rapid cooling of the stones, a brick structure is installed. In this case, it will take several hours for good heating.

If it is planned that the sauna will be used by many people, then it is better to install a continuous combustion stove. This allows you to maintain uniform heating and provide unlimited time for the steam room with a sufficient amount of fuel. A batch oven can also be used for a large number of people, but then it must have appropriate dimensions. Otherwise, the temperature will quickly drop and you won’t be able to get a good steam bath.

A continuous combustion furnace can be made from steel sheets with a thickness of 4-5 mm. In this case, the furnace parameters should be as follows:

- depth from 45 to 60 cm;

- height from 35 to 50 cm;

- width from 25 to 40 cm.

The permissible volume of the steam room reaches 12 cubic meters. m. 1 cu.m. m requires at least 6 kg of stones. The maximum weight of the heater is 150 kg. The container itself, intended for placing stones, is a kind of bunker. Thanks to this shape, it is possible to press most of the stones to the surface of the firebox for increased heat transfer. It is recommended to place the chimney structure in such a way that it passes through the heater.

Often there are variants of metal stoves that have double walls. In this case, there is no need to close the gap between the walls to speed up heat exchange in the room. Less common are stoves with a space between the walls filled with water.

Etna 20 Premium

This stove is distinguished by its original aesthetic design, and in addition:

- Innovative turbo-firebox ensuring high-quality combustion and economical fuel consumption;

- the developed ribbed surface of the firebox increases the total “heat removal” area and increases the service life;

- three-layer casing, creates soft radiation and comfortable conditions of outgoing steam;

- durable thermal glass, measuring 410 x 290 mm, makes it possible to admire and control the combustion process.

- Steam room volume: up to 20 m3

- Depth: 765 mm

- Width: 820 mm

- Height: 810 mm

- Weight of the “heat generator”: 90 kg;

- Weight of stones: up to 95 kg

The Etna model has a modification “26” (up to 26 m³ of heating), it is slightly larger in size and allows you to invest up to 120 kg of stone.

Vesuvius - sauna stoves, review of designs and models, recommendations

Inexpensive Vesuvius sauna stoves are captivating primarily because of their price. She is democratic. At the same time, the stoves are made of cast iron, quite thick, 8 - 12 mm in different places. Therefore, they are reliable and durable (the manufacturer talks about 30 years of actual service...) and at the same time extremely cheap.

Thick cast iron is the basis of a sauna stove

The body of Vesuvius sauna stoves is often made of cast iron, which users like. But you can also find options made entirely of steel...

The combustion chamber of a cast iron stove consists of two main components: the lower part of the firebox, the upper part of the firebox, connected to the bottom by 4 bolts, and a heat-resistant cord is laid between them. Above, a cover is bolted to which the chimney is attached.

There are two removable cast iron elements:

- above the combustion chamber there is a shaped flame stopper, which must be set to the position according to the instructions;

- at the bottom of the firebox there is a grate.

The firebox door is also made of cast iron; it can be decorated with heat-resistant glass. The enclosing gratings and ash pan are made of steel.

For everything the price is small - from 250 - 350 USD. for smaller models in the line, and up to 500 USD for medium sizes...

What size…

Manufacturers of metal sauna stoves are looking for a compromise between the size of the combustion chamber and the price. On the one hand, a large firebox for a sauna stove is good - a lot of long logs will fit in, the comfort of preparing firewood and servicing the stove increases, and the energy output from just opening the door...

On the other hand, the price and weight of the product are increasing; consumers simply will not buy a stove that is too expensive. Was it possible to find a middle ground in this matter in the Vesuvius sauna stove...

As many people note, shortened firewood is needed, since even 50 cm already extends beyond the chamber, although it is acceptable for use, but at the same time, the combustion chamber turns out to be sufficient in volume to heat the steam room in one load...

Overview of the model range and choice of sauna stove

When you come to the store, you can find a number of different models of the Vesuvius sauna stove.

- First of all, you need to differentiate between sizes. Each dimension is designed for its own steam room volume from 6 - 14 cubic meters, and up to several dozen. The greatest demand is for medium ones, designed for 12 - 24 cubic meters.

- Next is the fundamental question: steel body or cast iron? For a sauna stove, which is purchased for decades, experts recommend cast iron... You can see that the company offers excellent casting, and the cast iron is really thick, on average 10 mm.

- Door with or without glass... Glass creates the effect of a fireplace, you can see the flame and visually control the combustion. But this will come in handy when people are often in the waiting room...

- With an additional closed heater and steam generator or a simplified design. An additional steam generator makes it easier to saturate the room with steam and quickly transform a Finnish dry steam room into a wet Russian one... This is in demand.

An example of a review of the model range of sauna stoves in a store

The video provides an overview of the counter of VESUVIUS sauna stoves of different sizes and designs. How can you choose a stove for a steam room…. Consideration of the design features of different fireboxes and more in the video...

An example of the design and characteristics of a sauna stove for 450 USD.

As an example, we can consider the dimensions and design of a sauna stove designed for an average steam room with a volume of 12 - 24 cubic meters. The model is called LEGEND 22, made of cast iron.

- Fire door Vesuvius 271

- Heated from an adjacent room

- Height, mm 680

- Width, mm 560

- Depth, mm 750

- Weight of stones, kg 180

- Chimney diameter, mm 115

- Steam room volume, m3 12-24

How to set up a steam room with a Vesuvius sauna stove

When installing a stove, it is necessary to comply with the requirements of fire regulations and the manufacturer’s instructions in this regard. Instructions are included with the oven.

In particular, it is necessary to create fireproof, non-combustible areas of the enclosing surfaces - floor, ceiling and wall - with the specified dimensions at the place where the stove is installed. There are also a number of rules for arranging a chimney passing through the roof.

But all this does not make much sense if you do not create reliable and environmentally friendly thermal insulation for the steam room. How to insulate a steam room

The video shows an example of the design of a steam room with a VESUVIUS sauna stove.

Model Taal 14

Compact dimensions allow Taal 14 to be used in small bathhouses. The price is also quite “compact”. The stove can be placed so that firewood can be supplied from the steam room or from an adjacent room. Here are the parameters of this model:

- Steam room volume from 8 to 14 m3

- Double casing around the firebox

- Depth: 360 mm

- Width: 410 mm

- Height: 710 mm

- Weight of the stove itself: 57 kg

- Weight of stones: up to 40 kg

We recommend: How to paint lining inside a country house - beautiful and high quality

Design features:

- Furnace wall thickness: 5 mm

- Chimney diameter: 110 and 115 mm

- Length of laid firewood: up to 300 mm.

Two numbers written after the name of some Vulcan models indicate the maximum heated volume of the steam room in cubic meters. For example, Taal 14 means that the steam room that this model can “serve” is up to 14 m³.

Types of wood stoves: cast iron, steel, brick

The material from which the stove is made is crucial both for the rate of heat transfer, and therefore the heating time of the steam room, and for the service life of a particular stove.

The main division can be made as follows: there are brick (masonry) stoves and there are metal ones.

Brick

They are considered the most appropriate for a Russian bath, but not for a sauna. The high heat capacity of the brick prevents the steam room air from overheating during those long hours while the stones in the closed heater reach a temperature capable of producing light steam.

The mass of the stove brick together with the chimney can be quite large - one and a half tons, for example. Therefore, such a stove simply cannot do without its own foundation. And all together - the brick, the work of a professional stove-maker, the foundation - make it one of the most expensive sauna heaters.

BY THE WAY! Such stoves are never small, so they are installed in relatively spacious family or family-guest baths (if we talk about private steam rooms).

Steel

The exact opposite of a brick stove is a steel one. They are made of thin steel, with a thickness of 2 mm. It is clear that such a model can be not just compact, but even miniature, although with a compartment for firewood they cannot be absolutely tiny.

On the other hand, it is known that prolonged heating causes the iron to oxidize, become covered with scale and break down, forming holes in the body.

ON A NOTE! In steel stoves, the grade of steel from which it is made is of great importance. Structural steels burn out quickly. Alloyed (stainless steel) will also burn out, but not so quickly. Steels with a high chromium content are considered the best.

By the way, saving metal is not the only reason why manufacturers make the walls thin. Such a stove also quickly warms up itself, followed by the entire steam room. In a sauna, a thin-walled stove is more than appropriate.

Cast iron

The thickness of the wall or ceiling of a cast iron stove is greater than that of steel. But here, too, the grade of cast iron plays an important role in durability.

FOR YOUR INFORMATION! The best grades of cast iron are heat-resistant and alloyed.

Nowadays, it is much easier for companies to work with steel than with cast iron, so the number of models on the market made from this alloy is quite limited. However, the demand for them never falls. Because it is believed that a cast iron stove is almost as good for a Russian bath as a brick one.

Of course, in a Russian bathhouse they often don’t just install a cast-iron stove, although the heat capacity of cast iron is higher than that of steel. It is surrounded by a brick screen. Moreover, they will surround it in such a way that from the outside it will look like a real brick oven. In this case, you will also have to take care in advance to ensure that there is a reliable foundation under the stove.

Cast iron stoves for a wood-burning sauna are unnecessary, unless, of course, the durability of the unit is of paramount importance.

Design Features

Vulcan sauna stoves are produced with a thick firebox wall – 5mm carbon steel, which are additionally reinforced in areas of greatest load (here the thickness can reach 10mm). To make it convenient to clean the firebox and ventilation ducts from soot, there is a special hole with a lid on the top panel of the stove. The cast iron grates in Vulcans have a specific shape. They are designed so that even damp wood burns efficiently (it is often undesirable to burn with damp wood - the stove and chimney will quickly become overgrown with soot).

Bath stove "Vulcan". Design Features

After studies of “spent” own furnaces, carried out jointly with MSTU “Stankin”, certain design changes were made to the design of the “Vulcan” furnaces. A complex labyrinth of dividers appeared in the firebox, with the help of which the heated air is retained inside for as long as possible. In this way, maximum heat transfer from the heated air is achieved to the walls of the furnace and stones, and through them to the air in the steam room. To increase reliability, additional stiffening ribs were welded into the firebox. These fins simultaneously increase the heat transfer area, increasing the efficiency of the stove and the heating rate of the steam room and stones.

During the improvement, much attention was paid to welded seams, since they are the weakest link in any firebox. To prevent the seams from coming into contact with water, they are all made from the outside. To avoid deformation during heating, the new design is designed in such a way that almost the entire mass of the chimney falls on the reinforced pipe.

Oven "Vulcan Etna 20" with panoramic door and cast iron

Glass doors in wood-burning stoves are beautiful, but many have encountered the fact that the glass cracks due to temperature changes. The new Vulcan ovens are equipped with German doors with Schott Robax glass, which can be operated at temperatures up to 760°C. Moreover, what is more important, they do not crack under large differences: the temperature at the edges can be +50°C, and in the middle +500°C, and the manufacturer guarantees the absence of cracks. Their declared service life is 20 years.

Stove "Vulcan" for a bath. Schematic representation of the main design solutions

The design is well thought out from a safety point of view. A double metal screen is made to protect against hard radiation. It also serves as good protection against burns, since the temperature of the outer casing is not so high. The air flow created between the two layers of walls contributes to a more complete transfer of thermal energy into the air. Manufacturers also claim protection against the entry of combustion products (in particular, carbon monoxide) into the steam room by creating powerful draft.

All the improvements and changes in the design have led to the fact that instead of the previously stated 10 years of operation, today the service life of Vulcan bathhouse stoves has been doubled: manufacturers say that under normal operation they will last 20 years.