During the combustion of any type of fuel, soot and tar deposits accumulate on the internal heating surfaces of the boiler unit. They are good heat insulators and, with their significant thickness, reduces heat transfer from the internal heat exchanger to the heated water. In addition, such deposits clog the flow sections of the smoke ventilation system, as a result of which the speed of movement of flue gases in them decreases.

This process contributes to overheating of the structural elements of the boiler with subsequent failure. Soot, in addition, has the ability to ignite in smoke ventilation ducts, creating a fire in the house. For prevention and in order to prevent the occurrence of such dangerous processes, each heating boiler must undergo periodic cleaning of heating surfaces and smoke exhaust channels. And the owners of such equipment should know how to clean the boiler from tar.

Methods for cleaning a chimney

If there is little soot, it can be removed with potato peelings or salt.

Before cleaning the chimney pipe from soot, you should choose the appropriate method. There are only three of them: mechanical, chemical and manual cleaning.

With a mechanical method, a brush is inserted into the chimney, which knocks soot off the walls. This method cannot always be used, since not every pipe has good access. In addition, the entire contents of the pipes are poured down, after which the garbage must be removed.

The chemical method uses powders and logs. They are placed during the fire. Under the influence of temperature, substances are released that soften the soot and it flies into the pipe or falls down. It is better to use such products for prevention when there is little soot deposits.

Traditional methods are also used to clean pipes. The problem of soot formation is dealt with with salt or potato peelings.

If professional cleaning is required, you can contact the fire department and call a professional. The quality of work will be at the highest level, but you will have to pay for the services.

Mechanical cleaning

A brush with a weight for cleaning the chimney from the roof

This method of cleaning pipes involves the use of additional means. The most common devices are brushes. They come in different diameters for specific chimneys. The brush-ruff is placed on the end of a long and flexible cable; a metal ball can be attached under it for easier passage down. The structure is lowered into the pipe and raised, as a result, soot is cleaned from the walls.

Before you clean the chimney in the stove with your own hands, you should take care of technical safety. When working on a roof, you need to provide insurance to avoid falling. Gloves, goggles and respiratory protection will also be required. A respirator is needed because when cleaning, small dust particles are formed that get into the mouth and nose.

Before cleaning the chimney pipe in a private house, you should first place a container in the fireplace into which combustion products will fall.

Dry cleaning

Chemicals for soot removal

If the chimney in your country house is not too clogged, you can use various chemical compounds to remove a small layer of soot. If the chimney pipe is brick, such substances will allow mechanical cleaning to be done less frequently. As an independent cleaning product, they are used for chimneys made of ceramics or stainless steel.

Periodic use of chemical cleaning of soot from chimneys of stoves and fireplaces makes it softer, after which the residue is easier to remove mechanically. The combination of these two methods will keep the chimney free of plaque for a long time.

Among the most popular means for cleaning pipes from soot are the following:

- Kominichek. This is a Czech drug that is sold in paper bags in the form of granules. Place the bag on top of the wood in a preheated oven without tearing it. During the combustion process, substances will be released that will effectively clean the pipes. Recommended for use when the soot layer does not exceed 2 mm.

- Log. They are produced under the names Chimney Sweep and others. Boxes will vary in appearance depending on the manufacturer. The rules for use are the same - the log must be placed in a well-heated oven. During the combustion process, smoke will be released, softening the soot. It will evaporate or fall down.

- Powders for cleaning pipes. Available in the form of packages with prepackaged powder. The package should be placed in a hot oven. There are both domestic and foreign production.

Traditional methods

Aspen logs burn soot, but they are used only for prevention, so that if there is a large deposit of soot, a fire does not occur.

If it is impossible to clean the pipes mechanically or chemically, you can use folk remedies. The simplest of them is heating an already heated stove with aspen wood. The flame from them is hotter, the soot burns instantly. But this method cannot be used if there is a large deposit - soot can explode and damage the chimney. Therefore, before cleaning the chimney, you should inspect it. Aspen is recommended for use for prevention. When lighting, it is enough to add a couple of logs to the regular fuel.

There are safer ways to clean a chimney using folk remedies. Place a kilogram of table salt or a bucket of potato peelings into a hot and heated oven and heat it. They should first be dried so as not to lower the temperature in the firebox. The effect of the products will be milder than that of chemical drugs.

Mechanical soot removal technology

The most effective method to quickly bring a chimney back to normal is mechanical cleaning. The work is labor-intensive and requires the performer to comply with a number of rules.

Chimney sweep tools and equipment

Chimney cleaning devices used many years ago are still relevant today.

Indicative list:

- A metal brush with a diameter 20-30% larger than the cross-section of the chimney. For square pipes, a stiff brush is selected.

- Cable and brush holders.

- Steel round core with cable and carabiner. The diameter of the weight is 2/3 of the chimney section.

For cleaning, it is better to choose a brush with nylon hard bristles.

Polyamide bristles take the shape of the channel, and unlike a metal scraper, do not scratch the internal walls of the chimney. The high flexibility of nylon helps to get rid of plaque in hard-to-reach areas of the chimney

Before doing dirty work, you need to take care of personal protective equipment - wear long sleeves, glasses, a respirator and gloves, and put on boots with non-slip soles.

Working Conditions: Basic Safety

It is important to take the following precautions during the cleaning process:

- The inspection hatches of the chimney must be closed so that soot does not get inside the room and spoil the finish. Cover the open fireplace with a damp cloth.

- Work is carried out in calm, dry weather.

- Be sure to use a safety rope and belt.

- It is advisable to enlist the support of one responsible assistant.

- It is strictly forbidden to start cleaning while drunk, tired, or after taking medications that slow down the reaction.

It is necessary to inspect the chimney in advance for the presence of foreign objects, for example, bird nests.

If the socket is low, then it needs to be pushed in the direction of the combustion chamber. A high-positioned object can be reached from above

Step-by-step process of chimney cleaning

The whole process consists of several steps:

- Remove the pipe head from the top of the chimney and use a broom or long stick to remove visible dirt.

- Perform a test run with a weighting agent. The core should split large layers - small fragments will fall into the firebox.

- When the patency of the canal is restored, pull out the cable and connect the brush to the core.

- Clear a small area by lowering and raising the rope.

- Clean the rest of the chimney in the same way.

- Check the inspection chamber and remove any fallen soot.

The described technology is effective for straight chimneys - even at an angle of 45°, the passage of the core will be difficult.

Multifaceted professional brushes on a flexible shaft are designed for cleaning chimneys, ventilation systems and sewers. Markings on the cable allow you to control the depth of passage

How to clean a gas boiler at home

An integral element of any heating system is a gas boiler, which performs the function of generating heat to heat rooms. To ensure proper operation of this device, proper care will be required. During operation, it will be necessary to periodically clean the gas boiler from accumulated soot and other contaminants of various types.

How often is cleaning required?

The need for cleaning arises when certain negative aspects are detected during the operation of a gas boiler:

- a sharp decrease in temperature during stable operation of the device;

- increased gas and electricity consumption;

- the appearance of an unpleasant odor caused by carbon monoxide in the room.

Often the causes of these failures are clogging of certain elements inside the gas boiler. In order to understand exactly where the excessive accumulation of dirt has occurred, knowledge of the internal structure of individual elements is required, which can be studied in the technical documentation supplied with the gas boiler.

gas boiler device

Parts that require cleaning

This type of equipment contains the following elements that require regular maintenance and periodic cleaning:

- heat exchanger;

- igniter and burner with nozzles;

- chimney;

- filter component.

Maintenance of each individual unit requires a specific approach and has its own specifics of the work performed.

Igniter

When this element operates stably, its flame should look like a cone with a bluish tint. If the fire becomes yellowish in color, it is necessary to clean the contamination that led to the malfunction.

wire brushing

The order of work performed should occur in the following sequence:

- shut off the gas to the boiler using shut-off valves;

- get the igniter;

- use a brush with metal bristles to thoroughly clean;

- blow out;

- install the cleaned igniter in its original place.

After these steps, the color of the flame should again acquire a bluish tint. If this does not happen, it means that there are undetected contaminants on the igniter and a repeat cleaning procedure is required.

Burner with nozzles

This component is the main one in the design of a gas boiler. The element is intended for direct fuel supply.

example of soot

The sequence of work when cleaning the burner with nozzles is as follows:

- the valve on the gas supply pipe is closed;

- the burner is removed from its fixed installation location;

- the location of the injectors is remembered, after which careful dismantling is carried out;

- nozzles can be cleaned with an ordinary brush;

- the burner itself is cleaned using a brush, and the passage hole is purged using any hand pump;

- the nozzle is mounted back into the burner, according to the marks;

- the assembled element is installed in place.

Advice! This type of work is recommended to be carried out annually, before the start of the heating season.

Heat exchanger

The main purpose of this component in a gas boiler is the heating rate. The outer part may become covered with soot, which will significantly reduce operating efficiency. Cleaning of the presented unit is carried out mechanically at home.

This is what the heat exchanger looks like

To clean the heat exchanger from contaminants, you will need to acquire a certain set of tools, which includes:

- scrapers;

- brush with metal bristles;

- pipe cleaners of various shapes;

- a power tool, like a screwdriver with attachments designed for cleaning.

Advice! The best choice would be a tool that does not have sharp edges. Thus, possible damage to the heat exchanger during work is minimized.

The process itself goes as follows:

- the boiler is disconnected from the power supply and gas mains;

- the heat exchanger is carefully dismantled;

- cleaning is carried out using the most suitable and convenient tools;

- the cleaned element is installed back in accordance with the previous location.

There can be many reasons why internal parts become dirty, but the main one is poor-quality coolant, which causes scale to form on the walls.

If the presented material was useful to you, do not forget to like it

and

subscribe to the channel

.

Burner with nozzles.

This part is the main one in the design of wall-mounted and floor-standing gas boilers, since it is intended directly for supplying fuel.

The sequence for cleaning the burner with nozzles is as follows:

the gas supply valve closes; the burner is removed from its installation location; the location of the nozzle is noted, and then it is carefully unscrewed; You need to carefully clean the nozzle with a brush; the burner is cleaned with a brush, and its hole is purged using available pumping equipment; the nozzle is inserted into the burner according to the mark; the burner is installed in place.

It is important to know! The burner with nozzles should be cleaned once a year, preferably before the heating season!

Cleaning the gas filter.

This device is designed to purify incoming gas from various types of contaminants and impurities.

Therefore, it is very important to regularly clean the filter from accumulated clogging.

Cleaning the heat exchanger.

It is worth knowing that the main purpose of the heat exchanger of a double-circuit boiler is how much water will be heated and at what speed!

It is also necessary to understand that this element of the boiler unit can become clogged both inside and outside.

The outer part of the heat exchanger becomes contaminated with soot, which negatively affects its functioning. This boiler unit can be cleaned of soot mechanically, in other words, cleaning is done with your own hands.

The cleaning procedure is as follows:

- gas supply and power supply from the boiler is turned off;

- the heat exchanger is carefully removed;

- cleaning is carried out using convenient tools;

- the device is installed again in its place.

The cause of contamination of the inside of the device may be poor-quality coolant, due to which scale settles on the walls. As a result, the throughput of the heat exchanger decreases, which generally affects the functioning of the entire gas boiler.

The most optimal way to clean the inside of the heat exchanger is to wash it with chemicals. Among the reagents that are used to clean the internal walls, the following products can be distinguished:

- adipic acid;

- sulfamic acid solution;

- special gel.

- circulation pump;

- reagent container;

- electric heater.

The principle of cleaning the heat exchanger using a washing device such as a booster is as follows:

Heat loss calculator

Calculator for the number of radiator sections

Heated floor calculator

- to improve cleaning properties, the reagent is heated in a container;

- using a pump, the solution is supplied under pressure directly to the heat exchanger;

As a result of the circulation of the chemical, the scale lags behind the internal walls and comes out along with the waste solution.

Principle of operation

To figure out how to properly heat a boiler with coal, let’s understand the principle of operation of such devices. When coal burns, heat is released, which heats the heat exchanger with liquid. It is already, under the action of a pump system, supplied to the radiators, heating the air in the necessary rooms.

The equipment is quite simple. At the bottom there is an ash pit where slag and ash are collected. Above it are the grate bars, on which the fuel directly burns. The heat exchanger can be located either around the firebox or on top.

There are also air-heated coal boilers. They directly heat the air in the room. Their design is much simpler, since there is no intermediary in the form of a liquid coolant. They are used more for heating garages and industrial premises.

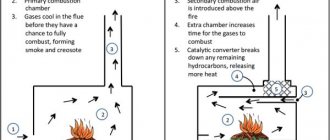

Long-burning models and pyrolysis devices have an increased level of efficiency. In the first, air is supplied from above, due to which only the top layer of fuel constantly burns. This allows you to load a lot of coal at one time, which will smolder slowly.

Sectional view of a coal pyrolysis boiler

In pyrolysis equipment, increased efficiency is achieved by additional combustion of volatile gases that are released during the oxidation of coal. For this purpose, they are equipped with specially shaped combustion chambers. In order for gas release to occur more actively, a particularly high level of temperature is maintained inside the furnace.

Causes of resin accumulation

The reason must be determined before cleaning begins in order for it to be effective.

The main reasons that provoke the accumulation of tar in boilers include:

- use of low-quality fuel;

- increased level of humidity of the material used;

- boiler operation at reduced temperature levels;

- Loading excessive fuel.

Types of pollution

For the operation of a solid fuel boiler, raw materials are required, due to which the combustion process will be carried out. Firewood, coal, peat and pellets act in this capacity. Each type of raw material has its own advantages and disadvantages. A common property is that during operation of the boiler, combustion products are released, which gradually accumulate on the internal parts of the chamber.

There are three main substances that pollute a boiler. The presence of each of them is due to certain factors:

- soot. Appears when the temperature during combustion of raw materials is not high enough. This is also affected by a lack of oxygen;

- resin. As a rule, its occurrence is due to various problems with the fuel: it may be too wet or of poor quality. Or you simply loaded too much raw material into the combustion chamber. A negatively influencing factor is also insufficiently high temperature;

- tar. The appearance of this substance indicates possible problems with the equipment itself. Either errors have crept into the design of the boiler, or the chimney was made too short, or the air flow is pumped into the chamber too weakly - the last factor is relevant for pyrolysis equipment.

Someone might think that a dirty boiler is not so bad, because all the deposits are hidden inside. In fact, the consequences can be quite negative. The performance of a solid fuel boiler depends on its cleanliness. With a high level of pollution, it will greatly decrease, as a result of which the house will become much colder, since the equipment simply will not be able to cope with heating the required volume of coolant.

In addition, such an attitude towards the boiler will lead to increased costs. First, fuel consumption will increase more and more as deposits accumulate inside the combustion chamber. Secondly, the boiler itself will quickly fail, and you will have to spend money either on repairing it or purchasing new equipment.

All these problems can be avoided quite simply:

use only high quality fuel; Initially, when choosing a boiler, pay attention to the compliance of its design with technical parameters; Perform preventative cleaning regularly. All this will significantly extend the service life of the equipment.

All this will significantly extend the service life of the equipment.

How can this harm?

A clean boiler works better.

The accumulation of resin on the walls of the unit in large quantities can lead to the following unpleasant consequences:

- every day the thermal capabilities of the boiler begin to decrease;

- the temperature throughout the house drops noticeably;

- the amount of fuel consumed increases;

- The service life of the unit is reduced significantly.

Cleaning a solid fuel boiler

When solid fuels burn, particles of tar, tar, and soot are concentrated on the inner walls of the furnace. All this negatively affects not only the heating of the room, but also reduces the service life of the equipment. Therefore, cleaning boilers of this type should be included in the list of regular maintenance.

Boiler clogged with soot and tarSource 1-teplodom.ru

Cleaning methods

For preventive cleaning of boilers operating on solid fuels (wood, coal, briquettes) there are 3 different methods. Moreover, each of them is radically different from each other, and has a number of certain difficulties. Let's take a closer look at them.

Mechanical

This involves manual cleaning of the boiler grate, its firebox, and the lower part of the chimney (if possible). This is done as follows:

- Heat the boiler. This is necessary to warm up and facilitate the removal of resin accumulated on the walls.

- After the stored fuel burns out, thoroughly clean the internal walls with the available tools (wire brush, spatula, poker and other devices). In this case, you should be careful not to damage the walls of the boiler.

- After cleaning is completed, flood the device again with non-resinous firewood. Thus, you will “burn out” the remaining particles of tar and soot.

Chemical

Cleaning the boiler in this way involves the use of special means designed to combat deposits of soot, tar, and carbon deposits. The most common are 2 methods:

- The heated inner walls of the boiler (according to the previously described principle) are sprayed with the composition and left for a short period of time. After impregnation, the plaque is removed mechanically. The use of concentrates in this case facilitates the removal of soot.

- Granular particle preparations are poured into the firebox when the boiler is flooded. As a result of the chemical reaction that occurs, the carbon deposits are destroyed and removed through the chimney.

For the first method, the following means are considered the most popular and reliable:

- Adipic acid. It is diluted with water and then applied to the inner walls of the boiler. The chemical process that begins converts soot and deposits into salt, which settles to the bottom of the device and is then washed off. Cost 1 kg. the drug varies from 170 to 200 rubles.

- Crystalline sulfamic acid. The principle of operation is similar: the walls are sprayed, after which the deposited sediment is removed mechanically or washed off with water. The cost of a kilogram is 80-90 rubles.

“Vitamins” for cleaning solid fuel boilersSource avatars.mds.yandex.net

Means for passive cleaning of boilers and chimneysSource obsi.ru

Among the means that allow you to clean the boiler and chimney using the second “passive” method, the following can be distinguished:

- Log chimney sweep. The name of the product comes from its appearance; in size and design it resembles an ordinary wooden log. This feature allows you to use the product in the process of conventional combustion, laying it together with standard firewood. Poleshka (one of its many names) contains ammonium sulfate and phosphorus oxide. Therefore, the manufacturer recommends not removing the paper packaging when placing it in the oven. Substances released during combustion penetrate creosote deposits and destroy them. After complete combustion of the product, its “healing” properties are preserved due to the fact that some of the components are retained in the walls.

- "Vitamins" for solid fuel. A prophylactic product, the use of which avoids the need for cleaning. The product is intended to improve the combustion of firewood, coal, and briquettes. The result is lower energy consumption, reduced concentration of soot and creosote on the boiler walls and chimney, and extended service life of the heating device. Thus, by periodically adding the product to the firebox, you can ensure that there is no need for mechanical cleaning of the equipment.

Steam

This cleaning involves the use of a steam generator. The principle of operation is that steam is supplied inside the firebox under high pressure. Under its influence, carbon deposits soften and can be easily cleaned mechanically.

Cleaning wood and coal boilers with steam Source pechdoc.ru

Coal boiler after cleaning Source photoline.ru

Raw materials for combustion process

In order to start the process of firing a solid fuel boiler, several types of raw materials are used:

- coal of various types;

- firewood from various types of wood, pellets;

- peat;

- briquettes

Important! During the combustion of this raw material, as a rule, ash, ash and other combustion products remain, which settle on the working surface of the combustion chamber, as a result, this has a negative effect on the operation of the boiler.

Cleaning methods

Probably every boiler owner thinks about how to clean the unit and how to do it correctly. There are four main ways to clean a boiler from soot, tar and tar. Their features include the following important points.

Mechanical cleaning.

It involves cleaning a solid fuel boiler from combustion products using a special set of tools, which includes the following elements:

- poker;

- scrapers of different sizes;

- blades of different widths;

- metal brushes;

- brushes of various configurations, you can purchase them in any store, for example, here: https://pelletshome.com.ua/.

It is worth understanding that cleaning the boiler from soot using these tools is carried out only when the unit has cooled completely.

Important point:

When cleaning a solid fuel boiler, the damper must be fully open.

As for cleaning the wood-burning boiler from tar and tar, the stages of work will be as follows:

- Initially, the unit is heated, since the resin and tar have a solid structure, which softens when heated;

- using blades and scrapers, substances are removed from the walls;

- After finishing cleaning, increase the boiler temperature for a while in order to burn out the remaining tar and resin.

Thus, we see that cleaning a solid fuel boiler from soot, tar and tar can be done with your own hands. Dry cleaning.

A special feature of this method of cleaning a solid fuel boiler from harmful substances is the use of various chemicals, and the entire scope of work can be performed using two methods:

- The product is poured directly onto the burning fuel (such substances contain a set of crystals that react with soot and resin, crumble them, and then come out along with the smoke).

- Using special chemicals, boiler working surfaces that are contaminated with tar and tar are treated (as a rule, the main components of these products are solvents and acid-based reagents).

Specialist's note:

When cleaning the boiler with chemicals, safety precautions must be observed!

"Soft blasting."

This method is considered an American technology for cleaning a pyrolysis or wood-burning boiler from combustion products.

Its essence lies in the fact that, using a special device, a special solution containing chalk and baking soda is applied to the contaminated surfaces of the boiler.

Steam cleaning of the boiler.

The essence of the method is that the walls of the boiler are processed using a steam generator, while the boiler unit also undergoes disinfection.

Cleaning a solid fuel boiler from soot, tar and tar can be done in a way that suits your financial capabilities and labor costs. And in conclusion, I would like to dwell on one more aspect of cleaning the boiler from combustion products. There are also several traditional methods for cleaning the boiler from soot and tar.

For example, salt is poured onto burning wood, which helps remove soot along with smoke. Also, dried potato peelings are placed on the burning fuel, which, releasing starch, significantly soften the contaminated surfaces for subsequent cleaning. We hope our information will help you to ensure that your home is always warm and cozy.

Watch the video in which an experienced user explains in detail how to properly clean a solid fuel boiler from tar:

An indispensable attribute of any heating system is a boiler, which acts as a heat generator for heating the home.

The modern heating equipment market is saturated with a very wide range of boiler units of various types. But they occupy a special place in this assortment, which are becoming more and more popular every day.

This trend is due to the fact that units of this type are very effective and economical devices for heating a country house or even an apartment. In order for a gas boiler to function smoothly and stably, it is necessary to properly care for it.

One type of such maintenance is other pollution. Let's talk in more detail about why to clean a gas unit, as well as in what ways this can be done.

Causes of combustion products and how to remove them

The by-products that appear during the combustion process are:

The reasons for the appearance of these substances lie in some important points:

- there is not enough oxygen for the combustion process;

- extremely low fuel combustion temperature.

Important! Do not forget that the chimney is an integral part of the heating system of the house, and just like the boiler, it requires periodic cleaning. You will find detailed information on how to carry out this procedure in our article “Cleaning the chimney”.

Factors that influence the appearance of resin:

- the fuel you use is of poor quality;

- the moisture level of the fuel material is very high;

- the temperature at which the boiler operates is quite low;

- you are loading too much fuel into the firebox.

Tar appears in several other cases:

- rather weak injection of air flow into the combustion chamber of the pyrolysis boiler;

- the unit is incorrectly designed;

- The height of your chimney is too low.

As you can see, the main reasons for the appearance of harmful substances are low-quality fuel, as well as the technical aspects of organizing the combustion procedure.

Important! Experts advise: use fuel that is only of high quality. Otherwise, the boiler will rapidly wear out, and you will constantly be thinking about how to clean the boiler from resin so that this procedure has a longer-term effect.

Periodic boiler cleaning

After learning how to fire a coal boiler, you need to learn how to clean it. These actions will help prolong the performance and neat appearance of the unit. During the smoldering process of coal at high temperatures, the device leaves a minimal amount of waste, which is dumped into the ash pit. The amount of waste is practically invisible; it becomes visible only after prolonged use of the device.

The entire combustion process takes place on a grate. But over time, the time comes when the solid fuel boiler needs to be cleaned. Such cleanup activities are not considered particularly time- or financially expensive.

These products are thrown directly onto hot coals, resulting in the formation of acrid smoke, which will remove all the toxins inside the boiler and chimney. In this case, the operation of the device can not be interrupted. In addition, the walls of the device can be cleaned with a brush and a wire brush, which are usually included when purchasing the equipment.

What should be the regularity of cleaning processes?

The interval between cleaning processes for wood, pyrolysis or pellet boilers depends, first of all, on the quality of the fuel material:

- if you use high-quality fuel, the boiler unit must be cleaned approximately once a month;

- If you use fuel of low quality and with a high level of humidity, cleaning should be done once every 15–20 days.

Important! Despite the above deadlines, you should always monitor the operation of your unit, and if there is a violation of the operating rhythm, you can clean the solid fuel heating boiler from tar outside the schedule.

How to clean a boiler using a chemical method?

These methods are extremely rarely combined. For the cleaning process to be successful, you will need:

- scrapers;

- brushes;

- scrapers

- screwdriver;

- fabric gloves;

- corresponding electrical devices (spreading and non-spreading heads).

Before any type of cleaning, the boiler must be turned off and the power source must be disconnected. After this, you need to turn off the gas tap and heating shut-off valves, then wait for the boiler to cool completely

When choosing a tool, pay attention to the absence of sharp edges and ends, which can damage the internal parts of the unit and subsequently cause corrosion.

Chemical cleaning of boilers is very common precisely because of the ease of the process. To do this, the reagent is heated to the required temperature, then, using a special pump, it enters the boiler system and enters into a chemical reaction with deposits and scale.

Acids for cleaning:

- adipic;

- sulfamic;

- gel.

Adipic acid is diluted with water and very carefully poured into the cooled boiler using a pump. Carbon dioxide affects carbonates, which are converted into acid salts and subsequently dissolved. After this, it is necessary to release the pressure and wait until the acidic salts precipitate, which is easily washed off with plain water.

Sulfamic acid must be diluted with water in a separate vessel, and then pumped under pressure into a cooled gas boiler. After some time, the boiler is washed with high pressure of water and dried. The gel is not an acid, but it is capable of dissolving any petroleum derivatives, as well as effectively separating scale from metal parts. The gel allows you to clean the gas boiler gently and carefully without damaging its walls.

After this, it is necessary to release the pressure and wait until the acidic salts precipitate, which is easily washed off with plain water. Sulfamic acid must be diluted with water in a separate vessel, and then pumped under pressure into a cooled gas boiler. After some time, the boiler is washed with high pressure of water and dried. The gel is not an acid, but it is capable of dissolving any petroleum derivatives, as well as effectively separating scale from metal parts. The gel allows you to clean the gas boiler gently and carefully without damaging its walls.

The disadvantage of chemical boiler cleaning is that the acid cannot be controlled. During exposure, along with scale, the acid reacts not only with deposits, but also with metal parts of the boiler that are not covered with dirt. This effect can be reduced by adding inhibitors to the cleaning composition.

Air heating in a country house is now not popular in Russia. This method has become widespread in Canada and the USA. Steam This type of heating is practically not used in cottages. It is mainly used in industrial facilities. It is economically and technically justified if steam is involved in the technological processes of the enterprise. Stove Heating with a stove is a well-known option. In country houses, stove heating is gradually giving way to more modern, efficient and easy-to-use options. It is impossible to heat a large cottage with a stove. In many homes, the stove is an element of interior design, rather than a source of heating. Heating system for country houses with liquid coolant Let's take a closer look at the most popular type of heating - water. Water heating systems, depending on the fuel used, are divided into the following classes: Systems running on gas (main gas, liquefied gas) Heating on electricity (with electric boilers) Systems running on solid fuel Systems running on liquid fuel From the point of view of comfort for accommodation, all designated heating options...

On the eve of the New Year holidays, pyrotechnic products are in great demand. In this regard, employees...

Areas of application

Depending on the thickness of the polycarbonate sheet, many designs can be made. Corrugated sheets with a wavy or trapezoidal structure are considered a good alternative to roofing coverings or an addition to them. It is also used for the construction of canopies, canopies, terraces and verandas. Honeycomb sheets are most often found in greenhouses and conservatories - this is where their properties are most in demand.

And also the use of polycarbonate sheets is relevant for the following areas:

- construction of a shower for a summer residence;

- creating a cover for the pool;

- fencing of sports grounds and public areas;

- glazing of greenhouses, winter gardens, balconies;

- production of swings, benches, gazebos, and other garden structures;

- formation of internal partitions in offices, banks and other institutions;

- production of advertising and information structures;

- road construction - as noise-absorbing shields, stopping pavilions.

Products made from sheet polycarbonate, thanks to simple and convenient cutting of the material, can have a decorative appearance. With its help, stylish transparent grilles are made for windows, curly hedges and gazebo frames. Smooth sheets are widely used in upgrading cars, bicycles, and motorcycles; they can be given different shapes.

When is cleaning possible?

In any case, it is inappropriate to wait until the moment when the device turns into a grimy “Cinderella”, so cleaning the gas boiler from soot is carried out at a certain time. There are three options.

- Periodic maintenance. It is a necessity. Owners are recommended to perform preventative cleaning of equipment at least once every 2 years. Better - once a year.

- Such a “cleaning” operation is required when the efficiency of a gas boiler decreases: heating of water for hot water supply is worse, heating does not work well enough. Usually in such circumstances a professional is called.

- Cleaning a gas boiler from soot during repair work. When a heat generator breaks down during the heating season, the technician who comes to fix it also does preventive maintenance - cleans the heat exchanger.

The first 2 cases are not very attractive for equipment owners, since they involve expenses due to the invitation of an “alien” master. Often you can handle cleaning yourself, but almost any rule has exceptions. For example, it is better not to experiment with a condensing boiler that has a closed combustion chamber. If the owner is completely unfamiliar with such a unit, then professional help is already a necessity.

Preventative cleaning of a gas boiler from soot - flushing the heat exchanger - is a simple operation, and it is also performed quite quickly. This procedure can be carried out independently without much difficulty.

There are certain symptoms that indicate the need to clean your equipment. These include:

- increased gas consumption due to clogged heat exchanger;

- an atypical hum inside the device due to pump overload;

- reducing water pressure in the DHW circuit;

- radiators that are not hot enough;

- constantly working burner.

All these signs may not only be symptoms of a clogged unit, so other possible causes of problems should also be taken into account when diagnosing the equipment yourself.

Single-circuit or double-circuit boiler - is there a difference?

Varieties of boilers do not in any way affect the time period after which it is necessary to flush the heat exchanger. It is much more important which liquid () circulates in the heating system and which is supplied for hot water supply.

When using process water that has undergone standard purification, the boiler can be flushed no more than once every four years. This removes a layer of scale (which still forms) and deposits that have a more complex structure. If you do not filter water before pouring it into the system, but use ordinary water from a centralized water supply, then flushing should occur more often, at least once every two years. This is due to the high content of chlorine in the liquid, which, upon contact with the heating element, settles in the form of scale.

Some users prefer to use antifreeze as a coolant. This liquid is of higher quality: it does not freeze even at low temperatures, releases heat more slowly, but heats up quickly. Unfortunately, antifreeze is poisonous

, and breaking down into components, leads to damage to metal structures. The heat exchanger through which antifreeze circulates should be cleaned at least once every 1.5-2 years.

Therefore, both single-circuit and double-circuit boilers require timely cleaning of the heat exchanger, the intervals between which are the same in all systems.

In order to clean the bithermal heat exchanger less often, it is necessary to take care not only of the quality of the coolant in the heating circuit, but also of the quality of the water in the DHW system. The water should be pre-purified and filtered. You should also take into account the fact that the process of scale deposition begins at a temperature of 70°C, its rate increases by 2 times with every 10°C increase in temperature. In this case, the process progresses, since the growing layer of calcium impairs heat transfer and the temperature of the heat exchange wall increases.