Probably every stove owner eventually has a question about changing the type of fuel. This happens for various reasons. For example, someone used to use wood before, but now wants to try coal or peat to fire the stove, since these types of fuel provide more heat. Or maybe buying firewood is more expensive for someone than buying coal. But be that as it may, you still need to know how to properly heat a stove with coal. Although not all stoves are suitable for this type of fuel. For example, you cannot put coal into a Russian stove; a Dutch stove is not suitable for it, since large soot deposits and significant overheating are contraindicated for it. But coal is suitable for potbelly stoves, steel, cast iron and other heating structures.

What stoves can be heated with coal?

Potbelly stoves are most suitable for using coal. You can store both firewood and coal in them. After all, the material from which they are made is heat-resistant; it can withstand high temperatures for a long time.

Coal is an excellent option for a potbelly stove

Experts do not recommend using coal to heat a Russian stove. After all, its design was originally developed for wood fuel. This is due to the fact that the combustion temperature of coal in a furnace is much higher than that of firewood or other types.

A Dutch oven is also not suitable. After using fuel in such a stove, its condition deteriorates significantly: deformation of the body and parts from high temperatures, accumulation of soot in the chimney.

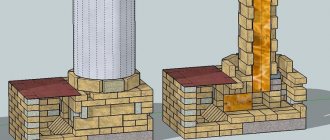

Heating a brick stove with coal is possible in two cases : if its firebox is lined with fireclay bricks, or if it consists of a steel frame with a wall thickness of at least half a centimeter.

Fireclay brick is resistant to high thermometer values; it can easily withstand the main temperature, while masonry made from ordinary bricks will be affected by less strong indicators. And thick steel will not deform and will easily withstand burning.

The grate in brick kilns fired with this type of fuel should be located two rows lower than usual. Coal fuel also requires an additional exhaust system.

If you equip an ordinary wood-burning brick stove correctly, then you can easily use coal to heat it.

Heating recommendations

Even a heating device designed exclusively for coal is fired using paper and a layer of wood. Coal is added only when the temperature in the firebox reaches a level sufficient for burning the rock. The first layer of coal material should be at least 6 cm. If the optimal size of the layer has not yet been determined by the owner of the stove, it is worth starting with this volume and increasing it to 15 cm if necessary, when the fuel burns well.

For heating boilers adapted for coal, the ideal shaft design includes vertical walls and a grate. The firebox is located at a sufficient height to ensure safe operation and the combustion process is not disturbed. During kindling, the coal is placed on the grate, with the valve slightly opened until the rock begins to burn well (then you can open it to maximum).

Dry fuel is best suited for kindling. Filling the stove with wet material is acceptable, but then the amount of soot on the walls will increase, and cleaning the grate and walls will be required earlier. The fuel, which is supplied after the first portion, is added only when the material poured in earlier has ignited efficiently.

Before supplying coal, always close the ashpit - this is a safety requirement first and foremost.

What kind of coal is suitable?

There are different types of fuel. Let's look at them in more detail:

- Lignite. The youngest species, characterized by high friability. It has a fibrous structure. A common fuel in power plants and factories. It is used infrequently for heating homes, as it does not heat a conventional stove properly.

- Brown. This fuel consists of peat and carbon. It has a low combustion temperature due to the large amount of water and other impurities. Can be used as local fuel.

- Coal . It has a high combustion temperature due to the large amount of carbon in the composition. Has a high heat of combustion.

- Anthracite. Contains up to 95 percent carbon. It has the highest degree of combustion heat. One disadvantage is poor ignition.

For heating stoves in households, coal and anthracite are usually used, as they have greater heat transfer. This type of coal for heating a home will be required several times less than brown coal or firewood. The only drawback is poor ignition.

This problem can be solved with the help of firewood: first put logs in the firebox, and after they burn out, add anthracite.

Long-flame coal has the best price-quality ratio. It ignites quickly, has high heat transfer, and is unpretentious in storage and use.

Owners' opinions

Below are some reviews from stove consumers.

“We purchased a stove for the Rus bathhouse with a fireplace door. It looks great and very presentable. And it works even better - a couple of clutches, and the steam room is already 110°C. Comfortable warmth without the feeling of suffocation. Economical fuel consumption coupled with a stylish design and an affordable price - Teplodar with both hands!”

Zarina Radina, Sverdlovsk region.

“The most affordable option for our home was the opportunity to buy a Teplodar gas stove. We doubted for a long time whether this would be an effective solution. But in reality everything turned out to be very simple and functional. The latest design of the stove allows you to steam comfortably after just 30 minutes of intense heating. No worse than wood heating. Thanks to the manufacturer, we were satisfied."

Sergey, Moscow.

“Based on feedback from friends, I decided to purchase a Rus stove from the manufacturer Teplodar. Outwardly, it is presentable; I was attracted by the increased manufacturer’s warranty of up to five years. Well constructed - thick, good steel. It’s a pity I didn’t immediately buy a tank for heating water; then I had to run around looking for a suitable one. I haven’t found any complaints in operation yet.”

Mikhail Badin, St. Petersburg.

“Our bathhouse is small, we only have enough money for it, so an electric stove is enough for us. We purchased a very inexpensive and practical option from the Teplodar company. We steam with pleasure, just like in a real Russian bathhouse. Installation is simple and consumes little electricity. Considering that we use the bathhouse once a week, the operating costs are quite reasonable. Overall, the result exceeded all expectations.”

Peter, Ekaterinburg.

Price

You can buy sauna stoves in many dealer stores, as well as on the website of the manufacturer Teplodar. The table shows the price of equipment without taking into account the cost of additional installation of a gas burner.

| Name | Dimensions (WxHxD), mm | Steam room volume, m3 | Price, rubles |

| Blast furnace 25 LC | 615x995x705 | 10-25 | 26000 |

| Cascade 18 LP Panorama | 380x920x770 | 10-18 | 20500 |

| Kuban 20 L | 500x865x700 | 10-20 | 19900 |

| Laguna 12 TK | 855x330x690 | 6-12 | 15000 |

| Teplodar Rus 18 LNZP Profi | 335x810x790 | 10-18 | 22600 |

| Rus Panorama 27 LNZP | 440x930x800 | 18-27 | 30800 |

| New Rus' 18 L (2004) | 395x815x805 | 10-18 | 13800 |

| Sahara 16 LRK | 785x380x755 | 8-16 | 17500 |

| Siberian cliff 20 health care facility | 835x565x730 | 10-20 | 26500 |

| Siberia 20 LRK Panorama | 785x375x750 | 10-20 | 23200 |

| Taiginka 10 TU | 405x330x705 | 4-10 | 8500 |

| Electric heater SteamFit 3 | 560x400x240 | 12 | 16700 |

| SteamGross 3 oven | 580x530x643 | 26 | 41000 |

Preparing the stove for lighting

Firing a stove with coal requires preliminary preparation of the heating device itself.

Before the start of the heating season, take a number of actions:

- Inspect the oven carefully. If defects are identified in the housing, repairs must be made: seal the cracks with mortar, replace parts, if necessary.

- Clean the chimney of soot. Large accumulations of combustion waste can cause improper air circulation or even fire in the structure.

- Check all doors, dampers, and latches.

If you have verified that there are no defects and that the heating structure is in good condition, you can proceed to the next step.

A set of measures before starting the fire

For the normal passage of the entire combustion process, it is necessary:

- carefully inspect the stove structure, starting from the firebox door of the stove and ending with the chimney. If cracks are found in the brickwork or chimney pipe, they must be sealed with a sand-clay mixture. Otherwise, the room will instantly fill with smoke, a large amount of carbon monoxide may appear, and small cracks will turn into large cracks and can actually damage the masonry;

- whitewash the pipe if you have not used the stove for a year or more;

- clean the chimney structure, including chimney channels, pipes from soot (if you have not used the stove for 3-4 months);

- clean slag and ash from the furnace. To avoid the appearance of dust in the room, combustion waste must first be filled with water, then raked out and taken outside;

- check for traction. To do this, insert a newspaper folded lengthwise into the firebox, set it on fire, and if smoke goes up the chimney, then everything is fine;

- use a dry cloth to wipe the outer part of the heating structure, otherwise an unpleasant odor will appear during the fire;

- Heat a little at a time 2-3 times a day, if the unit has not been heated for a long time, to prevent overheating of the stove.

*

Coal laying

How to heat a stove with coal correctly? Correct use of this type of fuel requires its special storage. Stones are poured into the firebox only after it is fully heated with the help of firewood.

First, paper, thin wood chips, sawdust or other flammable material are placed on the grate. The logs are not stacked very tightly on top, creating air gaps for better combustion.

Coal laying

Operating principle of a long-burning boiler

Boiler design diagram.

Automatic regulation consists of the control unit and the operation of the fan, which is responsible for the temperature of the coolant. The increase in coolant temperature depends on the access and volume of incoming oxygen, and the temperature in the system is controlled by a temperature sensor located in the water jacket of the boiler. When the set coolant temperature is reached, the oxygen supply is turned off and the fan stops operating. When the temperature drops below the set point, the automation transmits a signal to the fan, and it turns on and begins to pump oxygen into the boiler chamber, the smoldering coal again begins to flare up actively.

You can also heat the boiler in automatic mode: the boiler is in standby mode, that is, at certain intervals the fan turns on and allows the coal to die out: it maintains it in an undying state.

Ignition

After burning a batch of logs and pouring coal into the firebox, you need to monitor its ignition. If a small amount of coal fuel has already burned out, you can safely add the next one.

Adding additional coal

You just need to make sure that there are air gaps between the stones. They can be made with a poker. By opening and closing the blower we regulate the combustion process.

What not to do?

When burning coal in a stove, the following is prohibited:

- use pieces of bitumen, plastic, construction and household waste as kindling material;

- leave the vent and combustion door open at the same time;

- When lighting, use gasoline, kerosene, alcohol, and other flammable substances.

It should be remembered that adults should constantly monitor the combustion process and under no circumstances transfer this function to children.

To ensure maximum heat transfer, it is necessary that the coal be in the form of not too large pieces. It is not recommended to use excessively wet fuel, since during combustion a lot of steam will be released from its surface, which will significantly reduce the efficiency of the combustion process.

Features of kindling in winter

How to properly heat a coal stove in winter? In winter, cold air creates a special draft. It prevents smoke from escaping into the street.

- To ignite the stove in severe frost, you can use improvised means.

- If you have a hair dryer, take it.

- Close the ash pan door, open the firebox and valve.

- Preheat the oven for a few minutes and proceed with normal operations.

- After heating, smoke will not go into the room, and the fuel will ignite.

Why does smoke appear from a coal stove?

The stove is a complex structure that requires constant care, inspection and cleaning. This is a guarantee of safety and reliable operation of the stove, however, despite all efforts, troubles occur in the form of smoke. The main reasons for this situation may be a number of reasons:

- blockage in the smoke riser;

- the formation of cracks in the masonry, leading to a decrease in draft and temperature of exhaust gases, letting them into the room;

- quite strong cooling of the chimney;

- incorrect stove design;

- wear of the internal masonry.

Firebox rules and coal combustion temperature in the furnace

Basic Rules:

- Coal is added as it burns. Its thickness should not exceed 60 mm.

- When opening the firebox door, the vent should be closed.

- If the stove is equipped with a hob, the vent should be covered at any load. If this is not done, smoke will enter the room.

- The fuel should burn evenly.

- If you have a large amount of coal dust left over during coal storage, you can use it. How to properly heat a stove with coal dust? Wait until the bulk of the fuel burns, and then add a small amount of dust.

- When the combustion ends, you need to cover the vent.

- The chimney closes only when the coals have completely burned out.

It is not recommended to immediately heat the oven too much. It is better to do this gradually, so that a comfortable temperature will be maintained in the room for a long time. You should pay attention to the moisture content of the coal.

If the fuel has an excess of moisture, then less heat will be released during the heating process. This is due to the fact that drying requires significant energy expenditure.

The combustion temperature of coal in a conventional furnace can reach thousands of degrees. But usually it is much less - 600-800 degrees. The combustion temperature of anthracite at home is 500-600C, and the highest reaches 2100C.

Alternative fuels

Today, the most popular type of fuel used for heating residential and industrial facilities is coal. If desired, it can be replaced with alternative raw materials:

Peat

One of the most efficient types of fuel raw materials. Peat is suitable for stoves with special fuel chambers that increase draft during its combustion.

The material is produced in pieces and pressed briquettes. Peat moisture levels range from 22 to 40%, which leads to the formation of large amounts of ash. In terms of its calorific characteristics, it is significantly inferior to firewood, which is the main disadvantage.

Pellets

Fuel pellets are produced from dry biomass (sawdust, wood chips, bark and wood dust) by hot pressing. These are small capsules whose humidity level does not exceed 10%, so they are an excellent fuel for a brick or metal stove.

Unlike firewood, pellets can burn for quite a long time, releasing carbon dioxide and water. They are distinguished by environmental friendliness, safety and high calorific value.

Conclusion

Coal is the most common type of fuel. Its heat transfer is significantly higher than that of firewood, briquettes and pellets. Not all types of stoves can be heated with this product. To use it, you need a special firebox made of fireclay bricks or dense steel.

The process of laying, igniting and burning a corner will not require much effort if you follow the basic rules. But it will not be possible to heat the room with this type of fuel alone, since additional materials are required for ignition: paper, wood chips, small logs.

Periodic boiler cleaning

After learning how to fire a coal boiler, you need to learn how to clean it. These actions will help prolong the performance and neat appearance of the unit. During the smoldering process of coal at high temperatures, the device leaves a minimal amount of waste, which is dumped into the ash pit. The amount of waste is practically invisible; it becomes visible only after prolonged use of the device.

The entire combustion process takes place on a grate. But over time, the time comes when the solid fuel boiler needs to be cleaned. Such cleanup activities are not considered particularly time- or financially expensive.

These products are thrown directly onto hot coals, resulting in the formation of acrid smoke, which will remove all the toxins inside the boiler and chimney. In this case, the operation of the device can not be interrupted. In addition, the walls of the device can be cleaned with a brush and a wire brush, which are usually included when purchasing the equipment.